Material for table tennis and production method thereof

A table tennis and raw material technology, applied in applications, household appliances, other household appliances, etc., can solve the problems of many protruding parts at the bonding place, poor processing performance of materials, not found, etc., to shorten the grinding processing time, and the ability to resist blows. The effect of increasing and decreasing eccentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

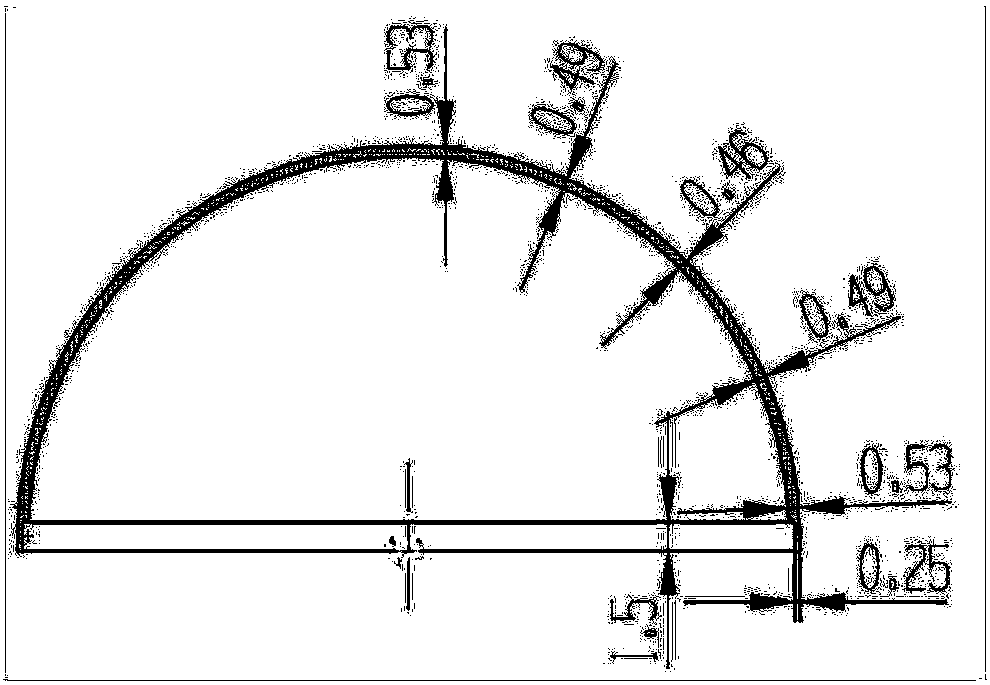

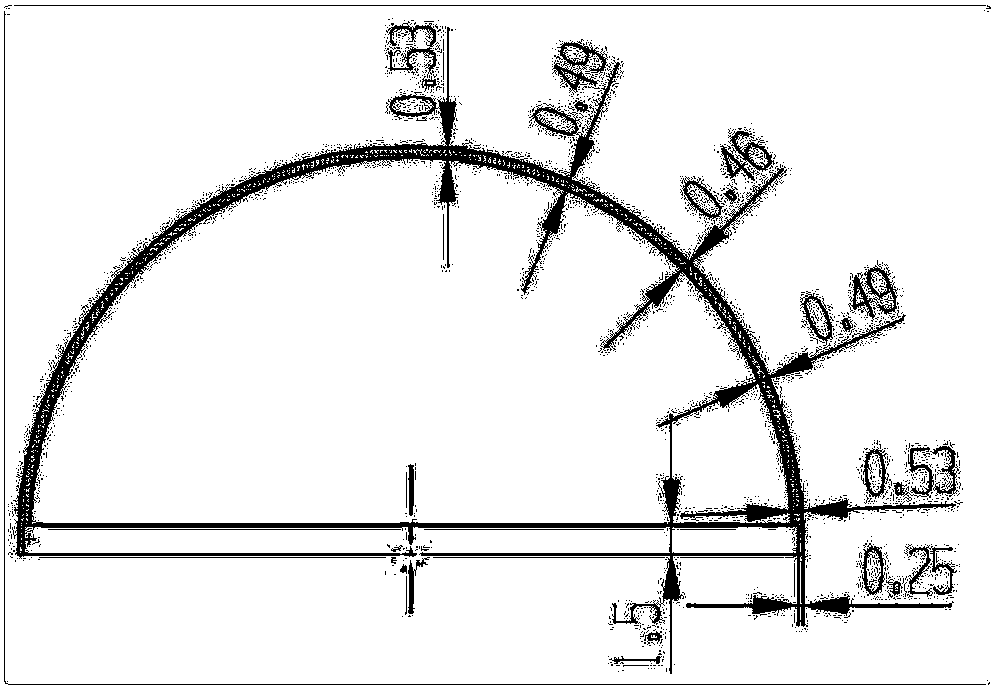

Image

Examples

Embodiment 1

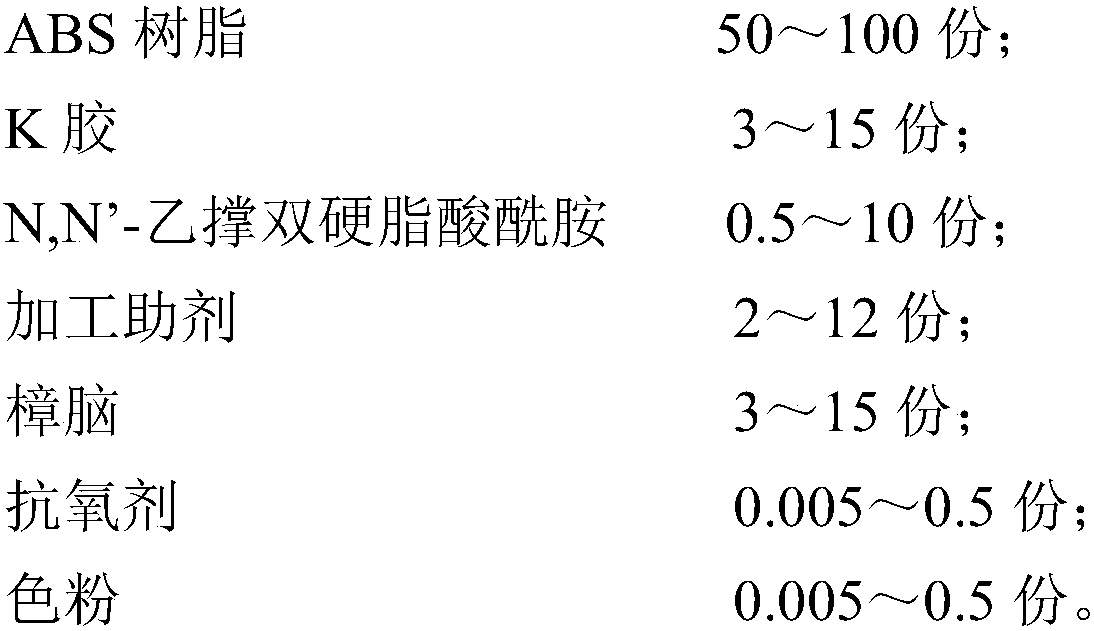

[0026] As an embodiment of the present invention, the table tennis material includes the following raw materials in parts by weight:

[0027]

[0028]

[0029] The production method of this table tennis material comprises the following steps:

[0030] According to the weighing of the above-mentioned raw material components, after high-speed mixing, they are extruded and granulated by a twin-screw machine to obtain the material for table tennis. The twin-screw machine adopts seven-stage temperature control, and the temperatures of each stage are respectively: 150 ° C, 160 ° C. ℃, 170℃, 180℃, 190℃, 200℃, 190℃.

Embodiment 2

[0032] As an embodiment of the present invention, the table tennis material includes the following raw materials in parts by weight:

[0033]

[0034] The production method of this table tennis material comprises the following steps:

[0035] According to the weighing of the above-mentioned raw material components, after high-speed mixing, they are extruded and granulated by a twin-screw machine to obtain the material for table tennis. The twin-screw machine adopts seven-stage temperature control, and the temperatures of each stage are respectively: 155 ° C, 165 ° C. ℃, 175℃, 185℃, 195℃, 205℃, 195℃.

Embodiment 3

[0037] As an embodiment of the present invention, the table tennis material includes the following raw materials in parts by weight:

[0038]

[0039]

[0040] The production method of this table tennis material comprises the following steps:

[0041] According to the weighing of the above-mentioned raw material components, after high-speed mixing, extrude and granulate through a twin-screw machine to obtain the material for table tennis, wherein the twin-screw machine adopts seven-stage temperature control, and the temperatures in each stage are respectively: 152 ° C, 162 ° C. ℃, 172℃, 182℃, 192℃, 202℃, 192℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com