Method for preparing sponge indium from polymetallic sulfide material

A technology of polymetallic sulfide and sponge indium, which is applied in the direction of improving process efficiency, etc., to achieve the effects of low processing cost, high indium yield, and mature equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

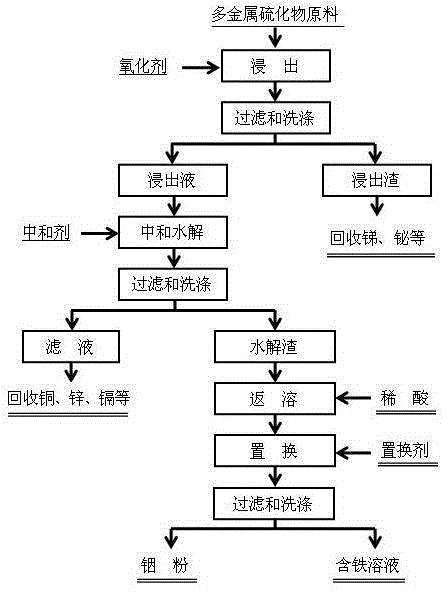

[0029] see attached figure 1 , Condition: The raw material composition of polymetallic sulfide is: iron 16.48%, copper 21.01%, lead 23.48%, zinc 3.56%, sulfur 12.48%, antimony 1.22%, bismuth 2.80%, cadmium 0.80%, indium 0.25%, silver 0.04% , all exist in the form of sulfides, weigh 3000 grams of polymetallic sulfide raw materials, the amount of nitric acid added is 3 times the weight ratio of the polymetallic sulfide raw materials, slowly heat to 85 ° C, the stirring speed is 250 rpm, the leaching time is 4h, and the leaching is over. Then, filter and wash to obtain leaching solution and leaching residue respectively. Add caustic soda to the leaching solution and stir to neutralize residual nitric acid, control pH to 3.0, filter and wash to obtain indium iron hydroxide precipitation and filtrate containing lead, copper and zinc, respectively. ; Indium-iron hydroxide mixed precipitation was added with dilute sulfuric acid to adjust the pH to 0.5, the precipitation was re-dissol...

Embodiment 2

[0031] see attached figure 1 , Condition: The raw material composition of polymetallic sulfide is: iron 16.48%, copper 21.01%, lead 23.48%, zinc 3.56%, sulfur 12.48%, antimony 1.22%, bismuth 2.80%, cadmium 0.80%, indium 0.25%, silver 0.04% , all exist in the form of sulfides, take by weighing 3000 grams of polymetallic sulfide raw materials, the oxidant is hydrochloric acid+sodium hypochlorite, and its addition is 5 times the weight ratio of polymetallic sulfide raw materials, slowly heated to 85 ℃, stirring speed is 250rpm, The leaching time is 6h. After the leaching is completed, filtration and washing are performed to obtain the leaching solution and leaching residue, respectively. The leaching solution is added with caustic soda and stirred to neutralize the residual hydrochloric acid, and the pH is controlled to 3.5. , copper, zinc and other filtrates; indium-iron hydroxide mixed precipitation was added to dilute hydrochloric acid to adjust pH 1.0, the precipitation was r...

Embodiment 3

[0033] see attached figure 1 , Condition: The raw material composition of polymetallic sulfide is: iron 16.48%, copper 21.01%, lead 23.48%, zinc 3.56%, sulfur 12.48%, antimony 1.22%, bismuth 2.80%, cadmium 0.80%, indium 0.25%, silver 0.04% , all exist in the form of sulfides, weigh 3000 grams of polymetallic sulfide raw materials, the oxidant is sulfuric acid + ammonium persulfate, and the amount added is 4 times the weight ratio of the polymetallic sulfide raw materials, slowly heated to 85 ° C, and the stirring speed is 250rpm, leaching time 5h, after leaching, filter and wash to obtain leaching solution and leaching residue, respectively, add caustic soda to the leaching solution to neutralize residual hydrochloric acid, control pH to 3.0, filter and wash to obtain indium iron hydroxide precipitation and Filtrate containing lead, copper, zinc, etc.; indium-iron hydroxide mixed precipitation, adding dilute hydrochloric acid to adjust pH 1.0, re-dissolving the precipitation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com