Organic selenium triazine polymer and preparation method thereof

A technology of organic selenium and polymers, applied in organic chemistry and other fields, can solve the problems of high temperature resistance, small addition amount, large addition amount, etc., and achieve the effects of good water resistance, good compatibility, and high decomposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1 The structural formula of the flame retardant described in the first embodiment is:

[0038]

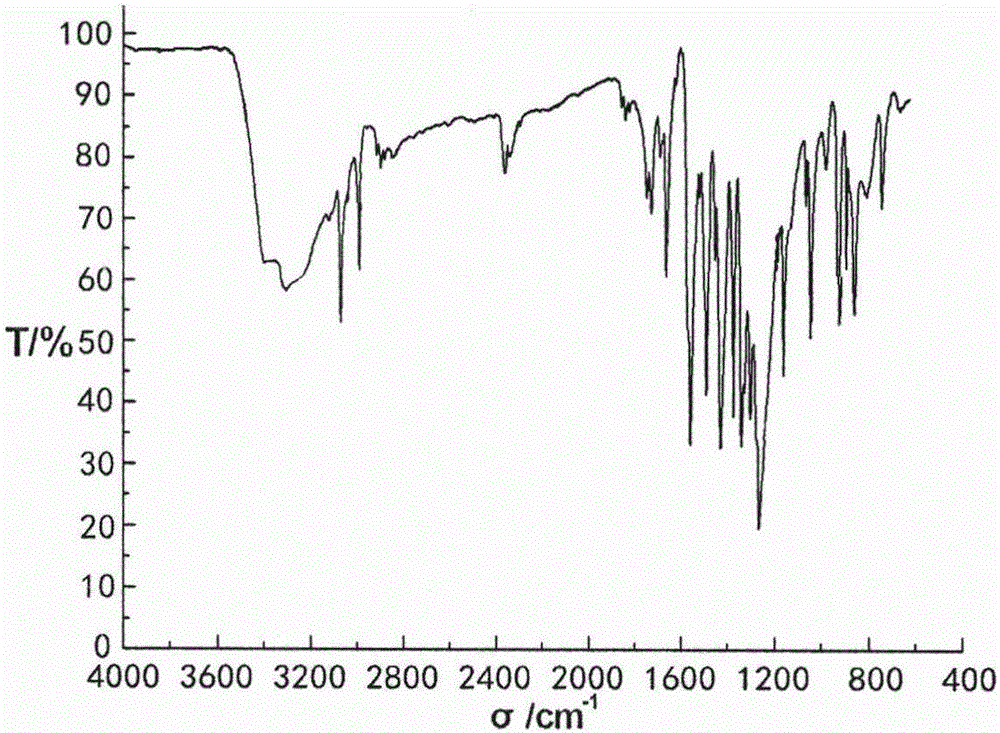

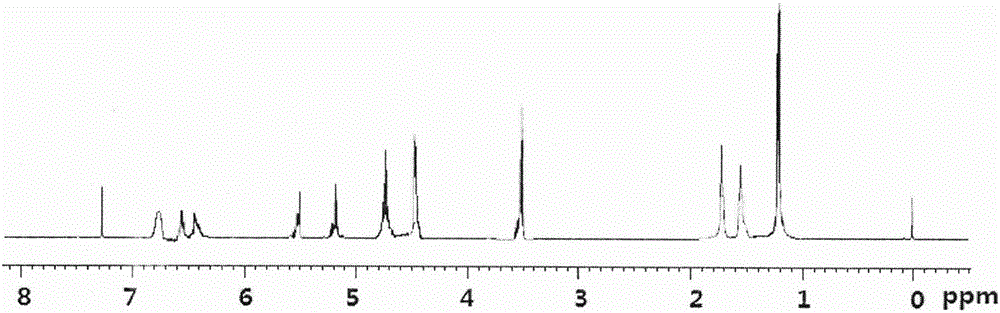

[0039] The preparation method is as follows: in a 500ml four-necked flask equipped with a stirrer, a thermometer, a constant temperature dropping funnel and a high-efficiency reflux condenser, add 250ml of acetonitrile and 29.72g (0.1mol) of triglycidyl isocyanurate, turn on the stirring, drop Add 6.92g (0.1mol) 65% ethylamine aqueous solution, control the temperature not to exceed 10°C during the dropping process, add dropwise for 3h, then keep the reaction at 30°C for 0.5h, so that the pH value of the reaction solution reaches 7-8; Then add 12.30g (0.1mol) selenourea, control the temperature not to exceed 50°C during the adding process, then raise the temperature to 60°C, keep the reaction for 8h, make the pH of the solution reach 7-8, after cooling, suction filter (solvent recycling) The product FR-1 is obtained after washing, drying and crushing; the yield is 98.5%,...

Embodiment 2

[0040] Example 2 The structural formula of the flame retardant described in the second embodiment is:

[0041]

[0042] The preparation method is as follows: in a 500ml four-necked flask equipped with a stirrer, a thermometer, a constant temperature dropping funnel and a high-efficiency reflux condenser, add 250ml of acetonitrile and 29.72g (0.1mol) of triglycidyl isocyanurate, turn on the stirring, drop Add 6.92g (0.1mol) 65% ethylamine aqueous solution, control the temperature not to exceed 10°C during the dropping process, and then keep the reaction at 30°C for 0.5h to make the pH value of the reaction solution reach 7-8; then add 13.80g (0.1mol) selenocarbazide, control the temperature not to exceed 50°C during the addition process, then heat up to 65°C, keep the temperature for 7 hours, and make the pH of the solution reach 7-8. After cooling, suction filtration (solvent recycling), water washing, The product FR-2 is obtained after drying and pulverization; its yield is 97.3...

Embodiment 3

[0043] Example 3 The structural formula of the flame retardant described in the third embodiment is:

[0044]

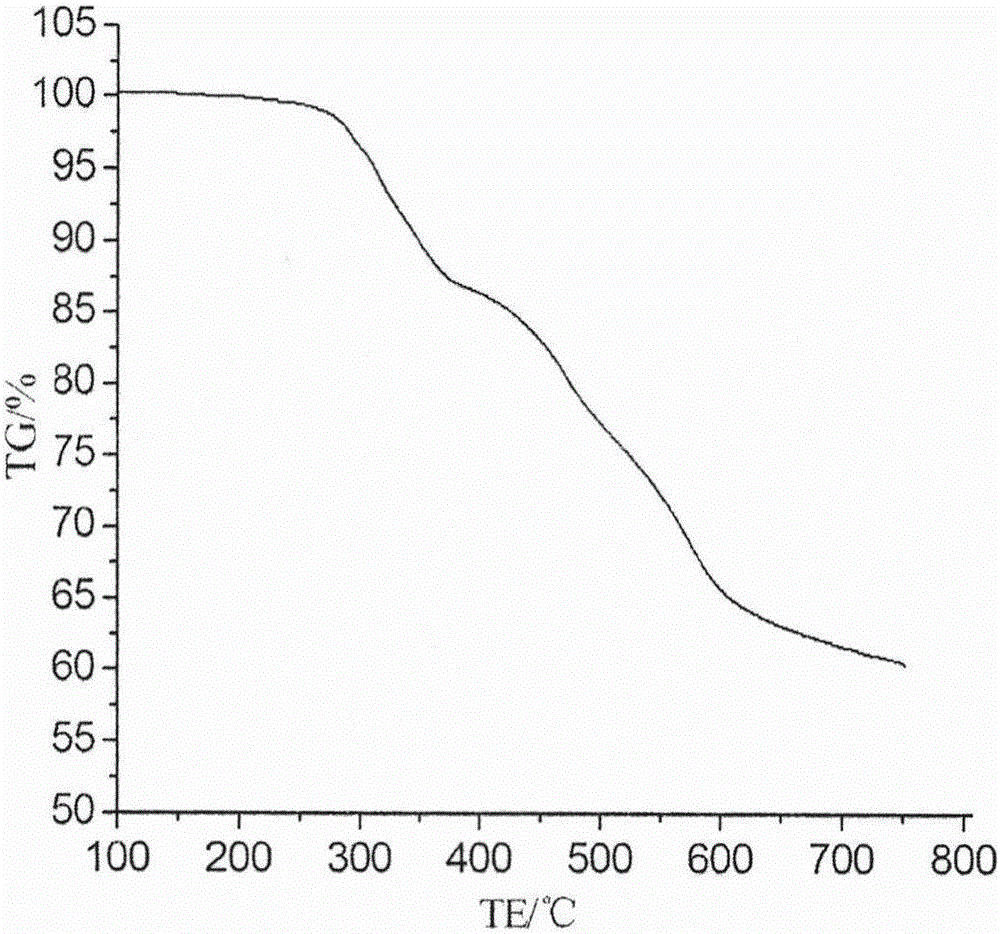

[0045] The preparation method is as follows: in a 500ml four-necked flask equipped with a stirrer, a thermometer and a high-efficiency reflux condenser, add 250ml of acetonitrile and 29.72g (0.1mol) of triglycidyl isocyanurate, turn on the stirring, and add 7.51g (0.1mol) ) Thioacetamide, control the temperature not to exceed 10°C during the addition process, then raise the temperature to 25°C, keep the reaction for 4 hours, make the pH value of the reaction solution reach 7-8; then add 12.30g (0.1mol) selenourea, and add it in the process Control the temperature not to exceed 50℃, and then reflux for 6 hours to make the pH of the solution reach 7-8. After cooling, suction filtration (solvent recycling), washing with water, drying and pulverizing, the product FR-3 is obtained; its yield is The decomposition temperature of 96.7% and 1% thermal weight loss is 288.3°C. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com