Metal-matrix composite material and preparation method thereof

A composite material and metal-based technology, applied in the field of improving the bonding strength of graphene and metal interface in metal-based composite materials, can solve the problems of failure of the reinforcement phase, failure of the reinforcement phase to play a bearing role, poor affinity, etc., and improve the bonding strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

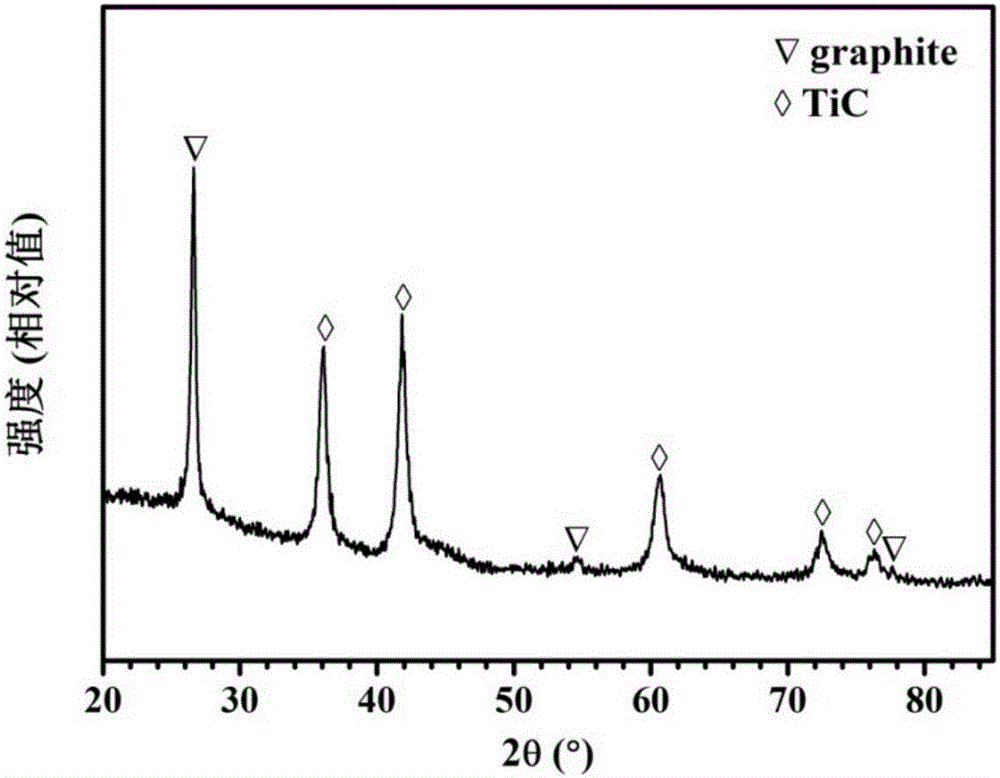

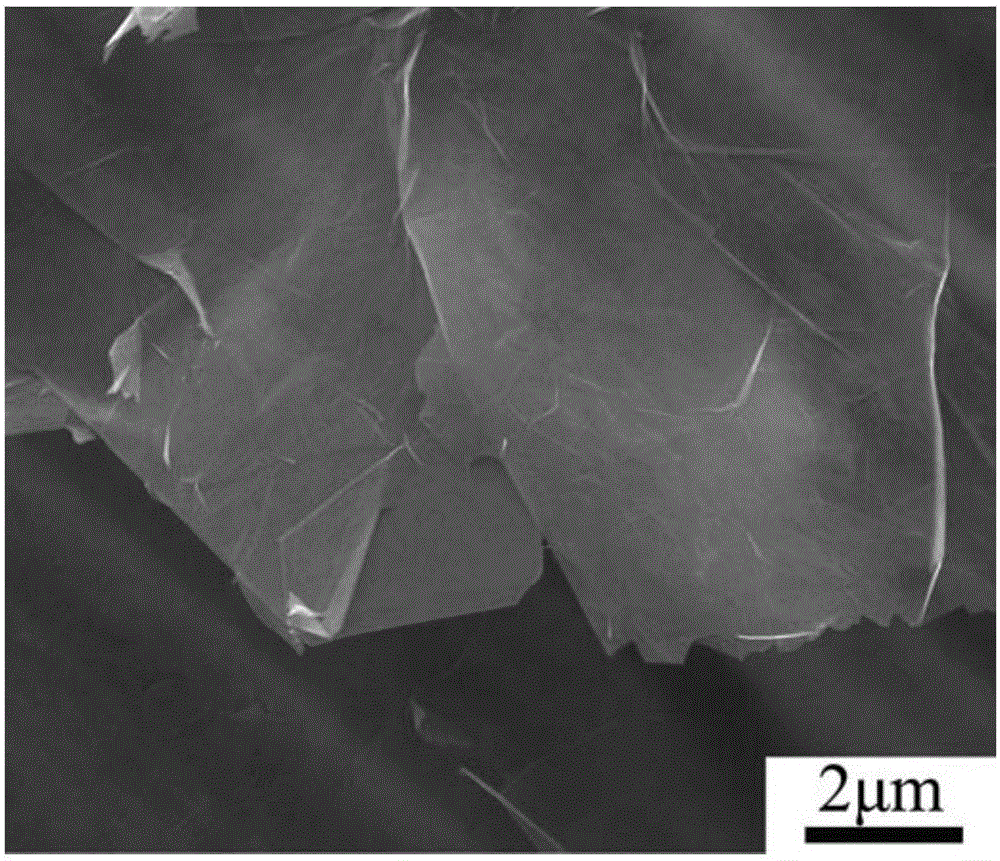

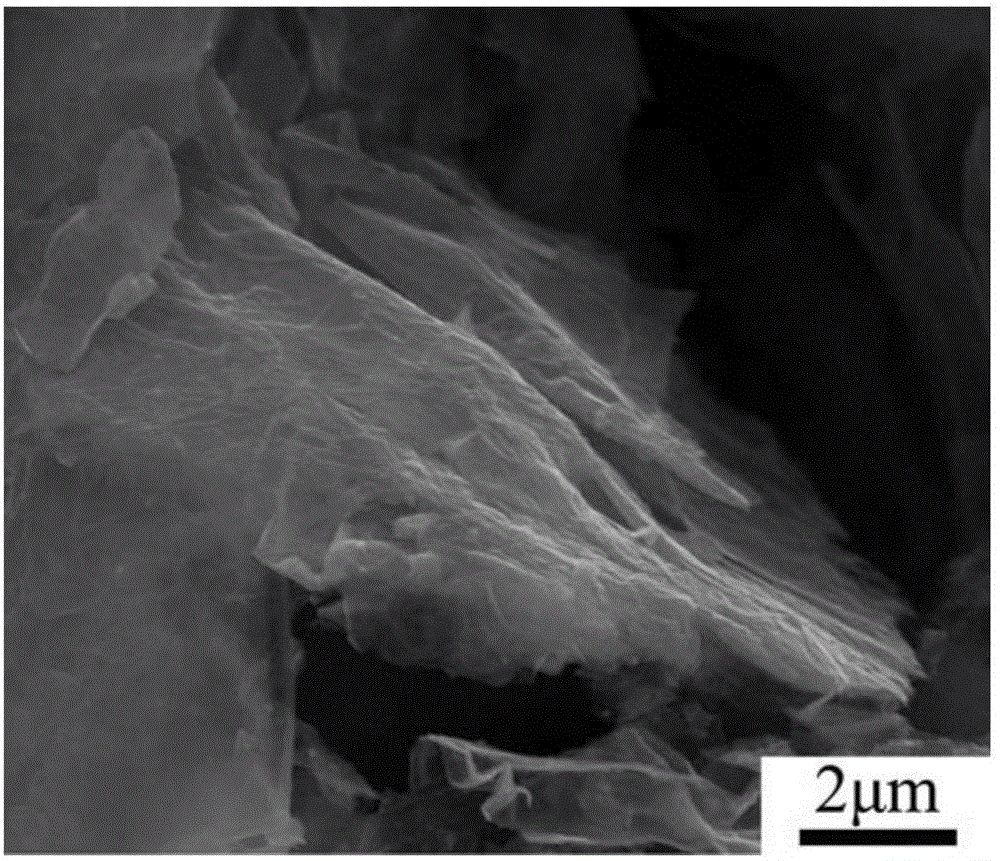

[0034] In this embodiment, the metal matrix composite material is based on aluminum, and graphene modified with titanium carbide is used as a reinforcement.

[0035] The preparation method of the graphene modified by titanium carbide is as follows:

[0036] (1) Take a certain amount of graphene powder, utilize NaCl:KCl=1:1 as mixed salt, utilize 300 mesh titanium powder as the titanium source of titanium carbide coating, three kinds of powders are according to molar ratio 5:5: 1. Put it in a ball mill jar and mill it for 10 hours, the ball milling speed is 150r / min, and the ball-to-material ratio is 1:1 to obtain the mixture;

[0037] (2) Place the mixture obtained in step (1) in a platinum crucible, seal it, and then place it under an argon protective atmosphere at 850° C. for 1 hour and then cool it with the furnace;

[0038] (3) Put the crucible and the reacted product in water, heat until the mixed salt is completely dissolved, then separate, wash and dry the solid to obt...

Embodiment 2

[0044] In this embodiment, the metal matrix composite material is based on copper, and graphene modified with vanadium carbide is used as a reinforcement.

[0045] The preparation method of the graphene modified by vanadium carbide is as follows:

[0046] (1) Take a certain amount of graphene powder, which is exactly the same as the graphene powder in embodiment 1, utilize NaCl:KCl=1:1 as mixed salt, utilize 300 mesh vanadium powder as vanadium carbide coating Vanadium source, the three powders are placed in a ball mill jar for ball milling for 10h according to the molar ratio of 10:10:1, the ball milling speed is 150r / min, and the ball-to-material ratio is 1:1 to obtain a mixture;

[0047] (2) Put the mixture obtained in step (1) into a platinum crucible, seal it, and then place it under an argon protective atmosphere at 1000° C. for 4 hours and then cool it with the furnace;

[0048] (3) Put the crucible and the reacted product in water, heat until the mixed salt is complet...

Embodiment 3

[0054] In this embodiment, the metal matrix composite material is based on copper, and graphene modified with chromium carbide is used as a reinforcement.

[0055] The preparation method of the chromium carbide modified graphene is as follows:

[0056] (1) Take a certain amount of graphene powder, which is exactly the same as the graphene powder in embodiment 1, utilize NaCl:KCl=1:1 as mixed salt, utilize 300 order chromium powders as chromium carbide coating The chromium source, three kinds of powders are placed in the ball mill tank for ball milling for 10h according to the molar ratio of 10:10:1, the ball milling speed is 150r / min, and the ball-to-material ratio is 1:1 to obtain the mixture;

[0057] (2) Put the mixture obtained in step (1) into a platinum crucible, seal it, and then place it under an argon protective atmosphere at 950° C. for 4 hours and then cool it with the furnace;

[0058] (3) Put the crucible and the reacted product in water, heat until the mixed sal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com