Preparation method for hyperbranched polycarboxylic acid polymer scale inhibitor

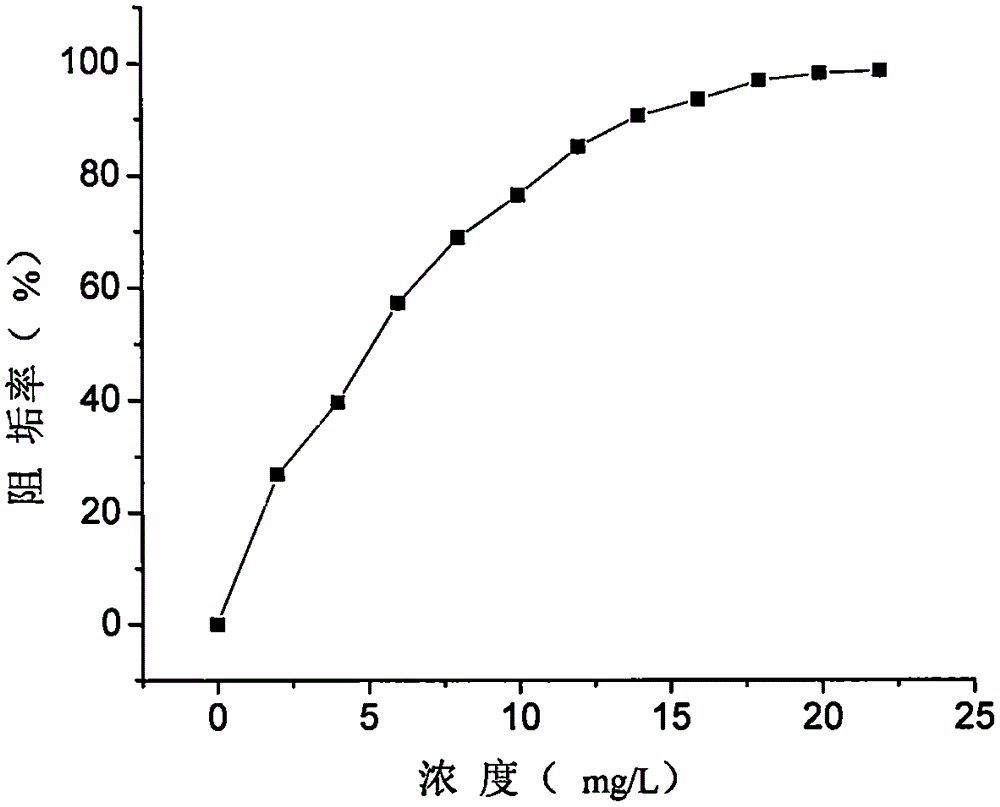

A technology of antiscalant and polycarboxylic acid, applied in chemical instruments and methods, descaling and water softening, special treatment targets, etc., can solve the problem of low maleic acid activity, unsuitability for industrial production, and high experimental control conditions and other problems, to achieve excellent scale inhibition performance, high scale inhibition effect, and improve the effect of scale inhibition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) in parts by mass, in a reactor with a stirrer, a thermometer and a condensing device, add 60 parts of propenyl alcohol, 38 parts of maleic anhydride, 1 part of p-benzoquinone and 1 part of anhydrous cobalt chloride, After stirring evenly, raise the temperature to 50°C, keep it warm for 12 hours, and measure the conversion rate to over 95%, remove the condensation, and remove the small molecules under vacuum conditions to obtain the functional monomer.

[0034] 2) Under vacuum conditions, add 30 parts of functional monomers, 20 parts of maleic anhydride, 48 parts of tetrahydrofuran, and 2 parts of benzoyl peroxide into a closed reactor, heat up to 70 ° C, keep warm for 8 hours, and The reactants are dried under vacuum conditions, and unreacted monomers are washed away with a small amount of mixed solvent, and the washed products are dried and hydrolyzed with saturated sodium bicarbonate to obtain a hyperbranched polycarboxylic acid scale inhibitor.

Embodiment 2

[0036] 1) In parts by mass, in a reactor with a stirrer, a thermometer and a condensing device, add 55 parts of propylene alcohol, 43 parts of monoethyl maleate, 1 part of hydroquinone and 1 part of anhydrous silica gel , after stirring evenly, raise the temperature to 70°C, keep it warm for 10 hours, and measure the conversion rate to over 90% to remove the condensation, remove the small molecules under vacuum conditions, and obtain the functional monomer.

[0037] 2) Under vacuum conditions, add 32 parts of functional monomers, 18 parts of maleic anhydride, 47 parts of tetrahydrofuran, and 3 parts of benzoyl peroxide into a closed reactor, heat up to 70 ° C, keep warm for 8 hours, and The reactants are dried under vacuum conditions, and unreacted monomers are washed away with a small amount of mixed solvent, and the washed products are dried and hydrolyzed with saturated sodium bicarbonate to obtain a hyperbranched polycarboxylic acid scale inhibitor.

Embodiment 3

[0039] 1) In parts by mass, in a reactor with a stirrer, a thermometer and a condensing device, add 65 parts of hydroxyethyl acrylate, 33 parts of maleic anhydride, 1 part of p-benzoquinone and 1 part of anhydrous chlorinated Cobalt, after stirring evenly, raise the temperature to 60°C, keep it warm for 12 hours, and measure the conversion rate to be more than 95%, remove the condensation, and remove the small molecules under vacuum conditions to obtain the functional monomer.

[0040] 2) Under vacuum conditions, add 35 parts of functional monomers, 20 parts of monoethyl maleate, 43 parts of acetone, and 2 parts of di-tert-butyl hydroperoxide into the closed reactor, and heat up to 70°C , keep warm for 10h, dry the reactant under vacuum condition, wash off the unreacted monomer with a small amount of mixed solvent, dry the washed product, hydrolyze with saturated sodium bicarbonate to obtain hyperbranched polycarboxylic acid scale inhibition agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com