Double split trench gate charge storage type insulated gate bipolar transistor (IGBT) and manufacturing method thereof

A charge storage and charge storage layer technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as reducing the switching speed of the device, increasing the switching loss of the device, and deteriorating the short-circuit safe working area of the device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

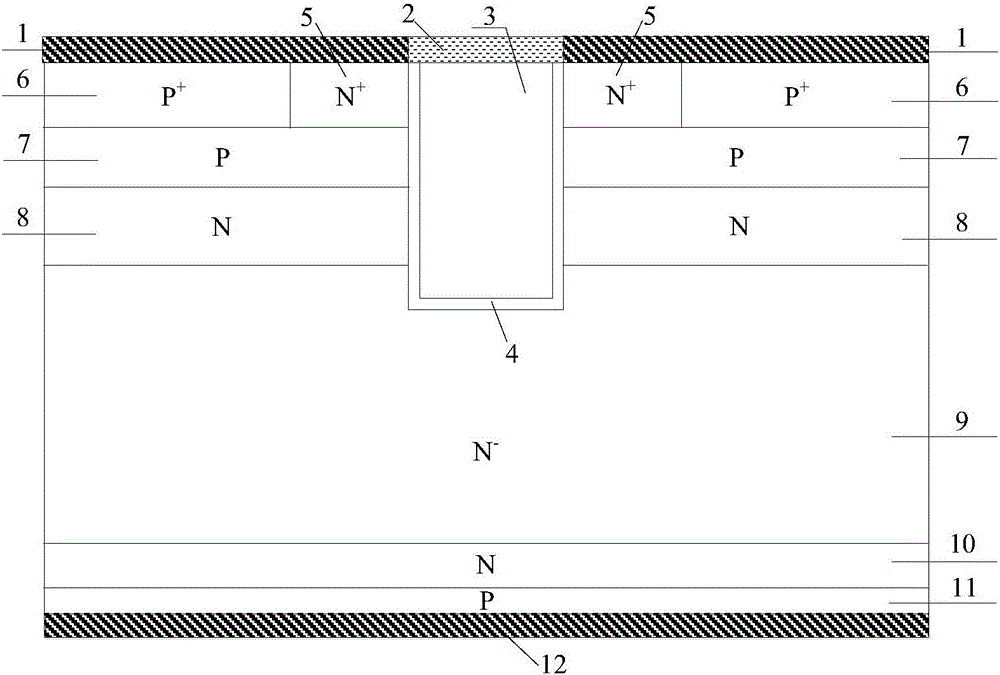

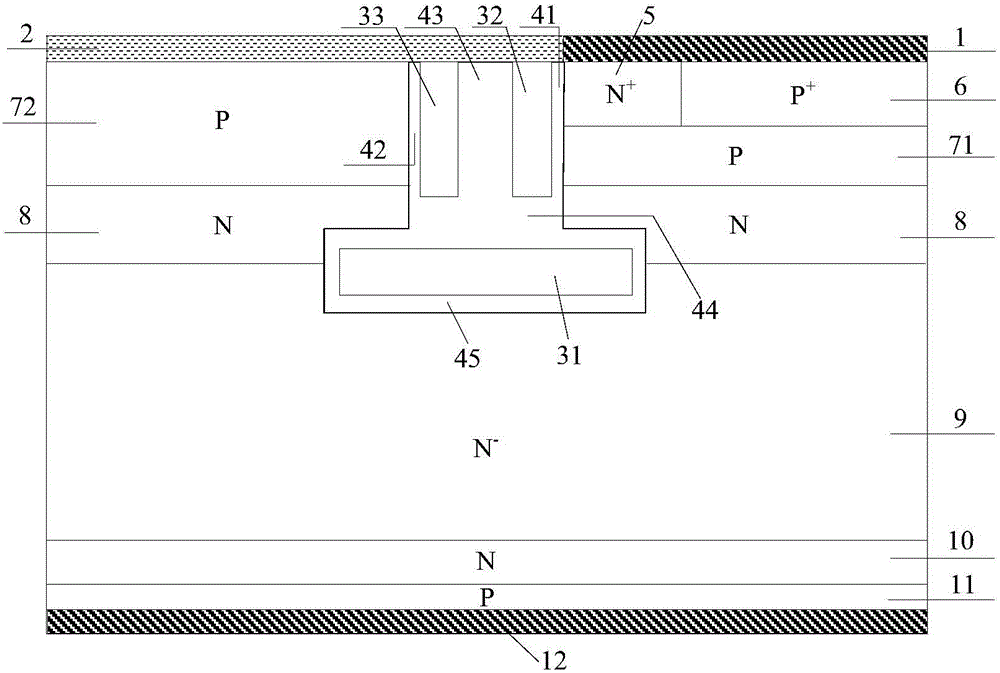

[0049] In this example, a double-split trench gate charge storage type IGBT, its cell structure is as follows figure 2As shown, it includes: the back collector metal 12, the P-type collector region 11 located on the back collector metal 12 and connected to it, the N-type field stop layer 10 located on the P-type collector region 11 and connected to it, The N-drift region 9 located on the N-type field stop layer 10 and connected to it; the compound double-split trench structure located in the middle of the upper part of the N-drift region 9 and connected to it; located on both sides of the upper part of the N-drift region 9 and connected to it The N-type charge storage layer 8, the sidewall of the N-type charge storage layer 8 is connected to the sidewall of the composite double split trench structure, the p-type base regions 71 and 72 located on the upper part of the N-type charge storage layer 8 and connected to it , the sidewalls of the p-type base regions 71 and 72 are con...

Embodiment 2

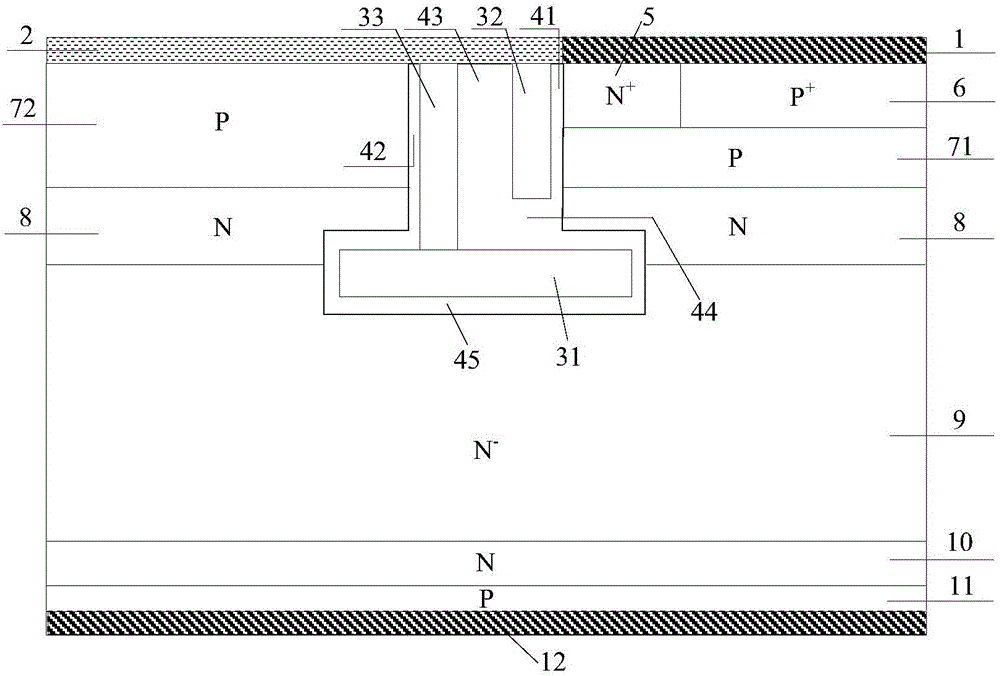

[0051] A double-split trench gate charge storage-IGBT in this example, its cell structure is as follows image 3 As shown, different from Embodiment 1, the lower part of the side split electrode 33 directly extends to the upper surface of the bottom split electrode 31, so that the side split electrode 33 and the bottom split electrode 31 are directly connected to further reduce the gate capacitance of the device.

Embodiment 3

[0053] In this example, a double-split trench gate charge storage type IGBT, its cell structure is as follows Figure 4 As shown, different from Example 1, there is also a layer of N+ layer 13 in the partial region between the lower layer structure of the trench structure and the p-type base region 71, and the concentration of the N+ layer 13 is greater than that of the N-type charge concentration of the storage layer 8 and its sidewalls are connected to the composite trench structure, the formed N+ layer 13 further reduces the resistance of the area between the underlying structure of the composite trench structure and the p-type base region 71, and further improves the The carrier injection enhancement effect at the emitter end can achieve a better compromise between the device's forward voltage drop and switching loss.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com