Method of repeatedly modifying polymeric thin films on plastic surface

A polymer film and multiple repetition technology, applied in the field of polymer film that can be repeatedly modified on the surface of plastics, can solve problems such as damage to the digestive system, and achieve the effects of low price, high yield, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of polymethyl methacrylate plastic with anti-bioadhesion properties

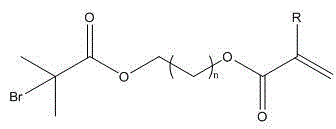

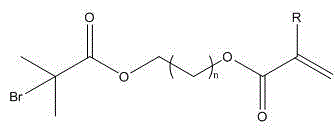

[0027] A. Put 24.4mL of 2-hydroxyethyl methacrylate and 87.7mL of triethylamine into a round bottom flask, and add 29.6mL of 2-bromoisobutyryl bromide and 100mL of dichloromethane dropwise with a dropping funnel The mixture was reacted at room temperature. After the reaction is completed, filter and wash repeatedly with hydrochloric acid, saturated sodium carbonate, and saturated brine respectively to obtain a light yellow oily liquid with aroma, which is separated with a silica gel column to obtain a bromine-containing initiator monomer. Add the bromine-containing initiator monomer into methyl methacrylate at a ratio of 5%, and then add a small amount of azobisisobutyronitrile as an initiator for continuous bulk polymerization, and stir well and evenly. First prepolymerize at 50°C for 5 hours, then pour the transparent and viscous prepolymer into a mold, and continue bulk polymerization ...

Embodiment 2

[0034] Preparation of polystyrene lubricated plastic with low coefficient of friction and reusable multiple times

[0035] A. The synthesis of bromine-containing initiator is as described in Example 1. Add the bromine-containing initiator monomer into styrene at a ratio of 1%, and then add a small amount of azobisisobutyronitrile as an initiator for continuous bulk polymerization, and stir well and evenly. First prepolymerize at 90°C for 1 hour, then pour the transparent and viscous prepolymer into a mold, and continue bulk polymerization at 200°C for 6 hours to obtain a modified polystyrene transparent plastic;

[0036] B. Add 9g of sodium methacrylate, 62mg of 2,2-bipyridine, 288mg of cuprous bromide, and 27mL of deionized water into the reactor, stir well under the protection of argon, and add the initiator into the reactor to integrate polystyrene sheet plastic. The reaction was carried out at 60° C. for 12 hours. A polystyrene plastic sheet modified with a sodium polym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com