A kind of preparation method of cerium-doped barium tantalate for gamma ray shielding

A technology of gamma ray and barium tantalate, which is applied in nanotechnology, chemical instruments and methods, tantalum compounds, etc. for materials and surface science, can solve the problems of excitation limitation in the visible light region and large forbidden band width, etc., and achieve composition Single, reduced bandgap width, and absorption-promoting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

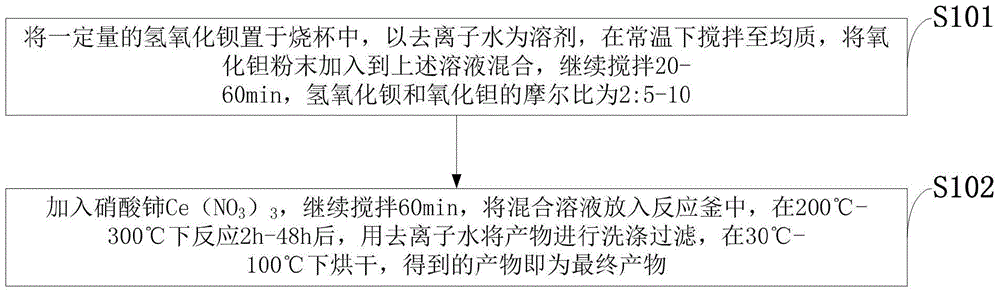

[0029] Such as figure 1 As shown, the preparation method of the cerium-doped barium tantalate for gamma ray shielding according to the embodiment of the present invention comprises the following steps:

[0030] S101: Put a certain amount of barium hydroxide in a beaker, use deionized water as solvent, stir until homogeneous at room temperature, add tantalum oxide powder to the above solution and mix, continue stirring for 20-60min, barium hydroxide and oxide The molar ratio of tantalum is 2:5-10;

[0031] S102: Add cerium nitrate Ce (NO 3 ) 3 , continue to stir for 60 minutes, put the mixed solution into the reaction kettle, react at 200°C-300°C for 2h-48h, wash and filter the product with deionized water, and dry it at 30°C-100°C to obtain the product is the final product.

[0032] Described cerium source is cerium nitrate or cerium oxide; (Ce(NO 3 ) 3 or (CeO 2 ).

[0033] In the present invention, the molar ratio of barium hydroxide and tantalum oxide is 2:5-10.

...

Embodiment 1

[0039] Put barium hydroxide in a beaker, use deionized water as solvent, stir until homogeneous at room temperature, add tantalum oxide powder to the above solution and mix, continue stirring for 20-60min, and finally add cerium nitrate Ce (NO 3 ) 3 , continue to stir for 60 minutes, put the mixed solution into the reaction kettle, react at 200°C-300°C for 2h-48h, wash and filter the product with deionized water, and dry it at 30°C-100°C to obtain the product That is the final product, wherein: the molar ratio of barium hydroxide and tantalum oxide is 2:5-10. The moles of cerium and the total moles of cerium and barium are 2%-16%.

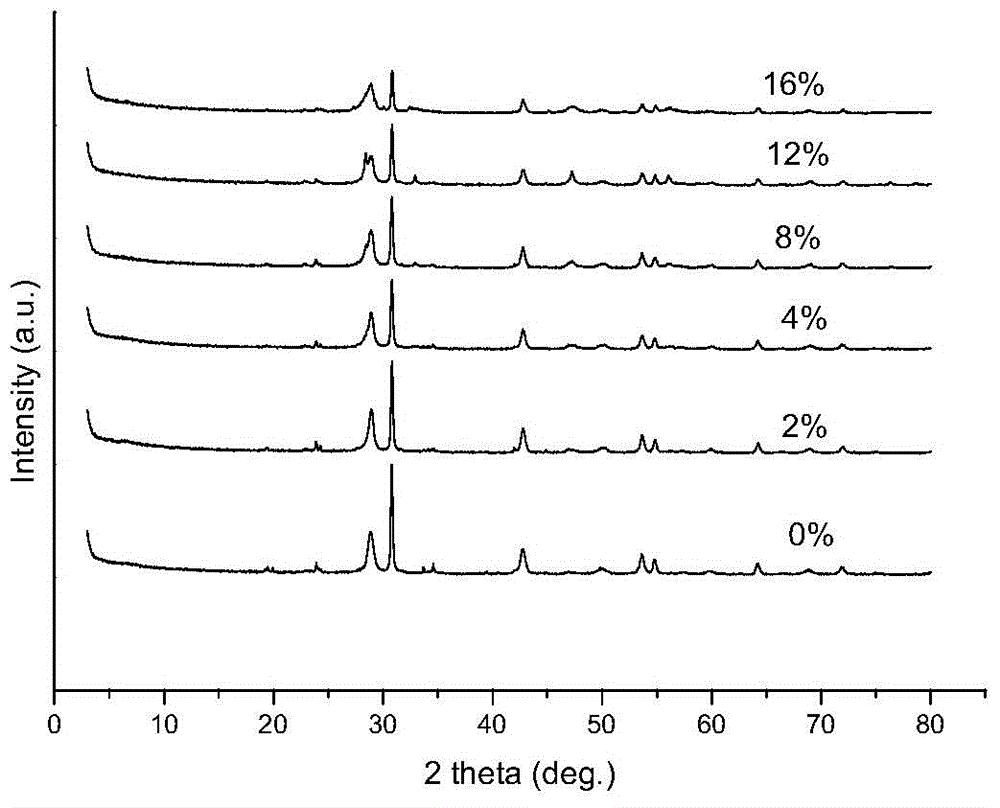

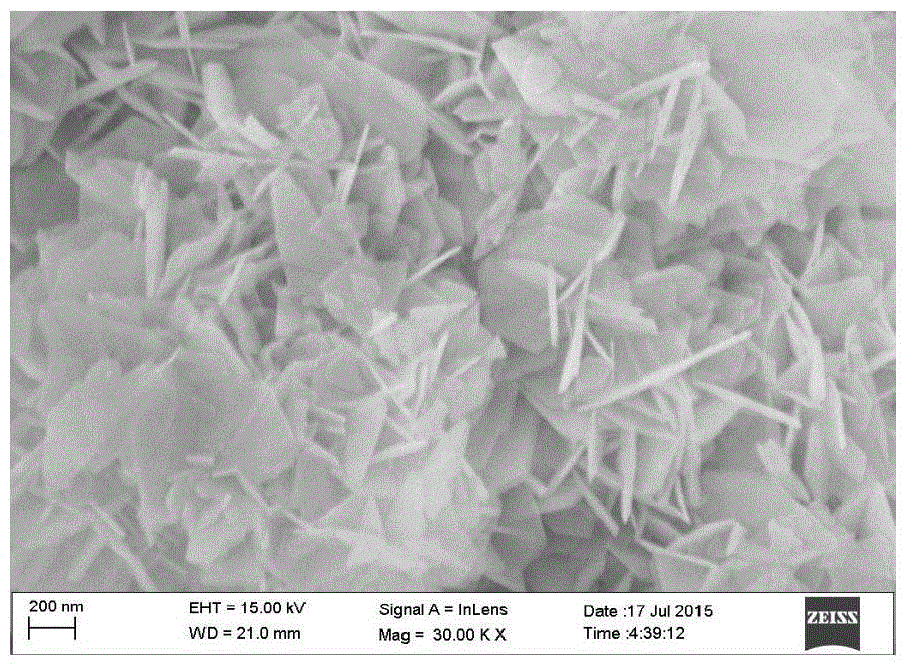

[0040] The structure and properties of the product were characterized by X-ray diffraction (XRD), scanning electron microscope (SEM), transmission electron microscope (TEM), X-ray photoelectron spectroscopy (XPS), diffuse reflection and fluorescence emission spectroscopy (PL), respectively. From figure 2 It can be seen that the XRD result shows...

Embodiment 2

[0042] Ba doping of EPD and Ce by two-roll mill 5 Ta 4 o 15 Mix the powder, add raw rubber, zinc oxide, stearic acid, cross-linking agent TAIC, anti-aging agent 4010A, Ce-doped Ba 5 Ta 4 o 15Powder, paraffin oil, vulcanizing agent DBPH. The rubber material was vulcanized on a flat vulcanizing machine, and the vulcanization conditions were 160°C, 13MPa, 30min. The mass proportion of the inorganic powder in the prepared composite material is about 40%.

[0043] Use 3 "x3" NaIγ spectrometer system (provided by Beijing Institute of Chemical Defense, and its radioactive source is 241 Am, the energy is 59.5keV, and the detector used is NaI(TI) to test the gamma ray shielding performance of the composite material, the results are as follows Figure 7 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com