Novel nano-crystalline cellulose modified lithium ion battery diaphragm and preparation method thereof

A lithium-ion battery and nano-cellulose technology, which is applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as low liquid absorption rate and liquid retention rate, poor electrolyte affinity, and battery safety hazards. Achieve the effects of less air bubbles, reduced defoaming time, and superior liquid absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific embodiments. The described embodiments are only preferred embodiments of the present invention, and are not intended to limit the present invention. For those skilled in the art, the present invention may have various modifications and changes. Any modifications, equivalent replacements, improvements, etc. made within the spirit and principles of the present invention shall be included within the protection scope of the present invention.

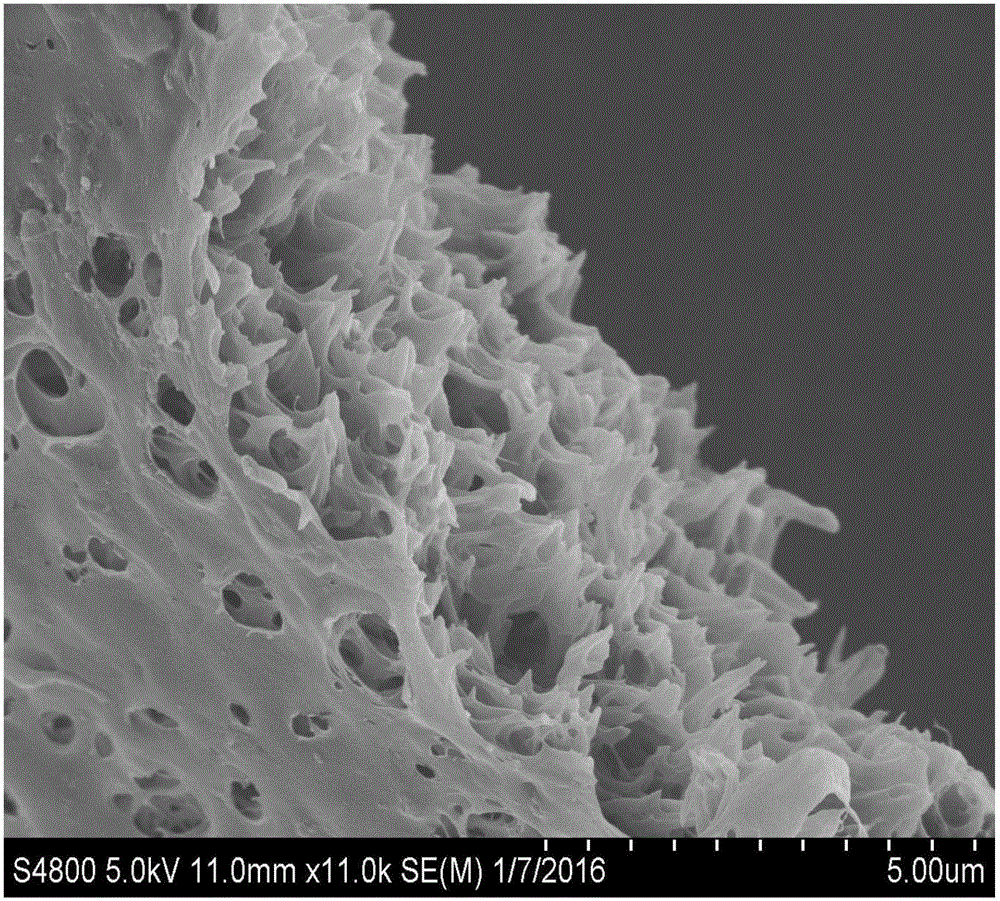

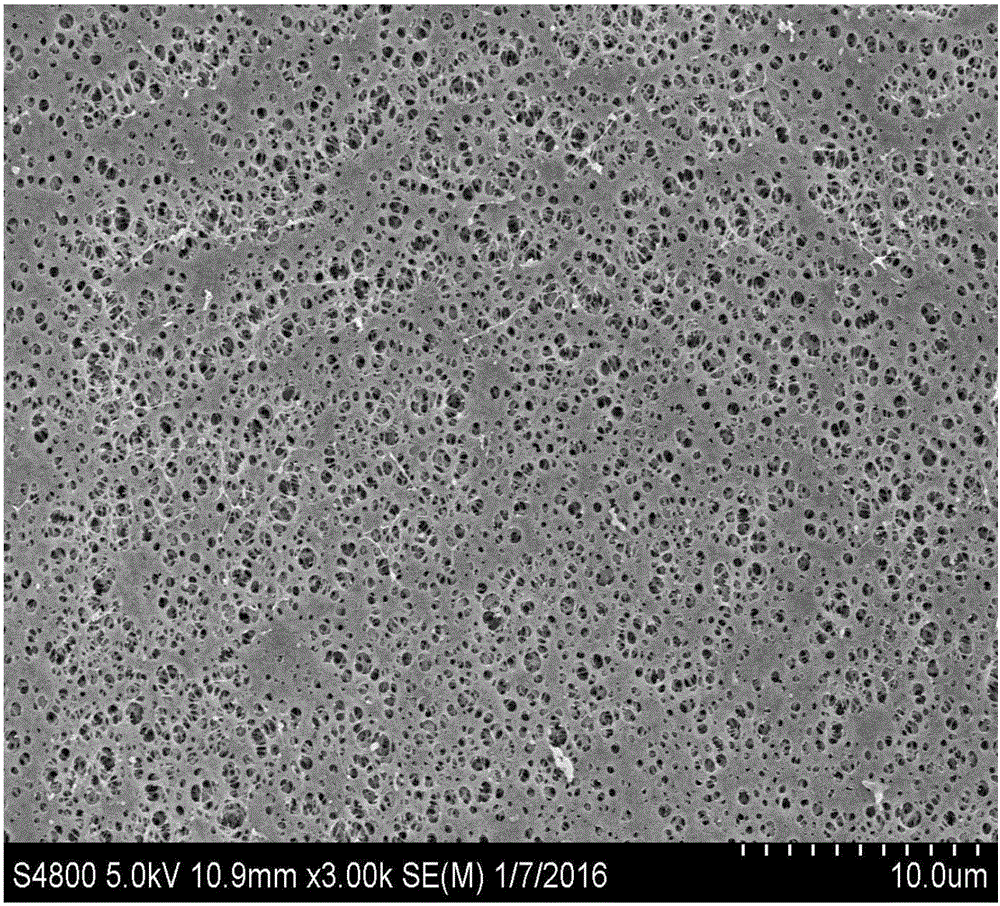

[0034] (1) The polymer matrix is polyvinyl alcohol with a molecular weight of 77000. Cellulose nanofiber-lithium accounts for 0.1-20 wt.% of the polymer matrix.

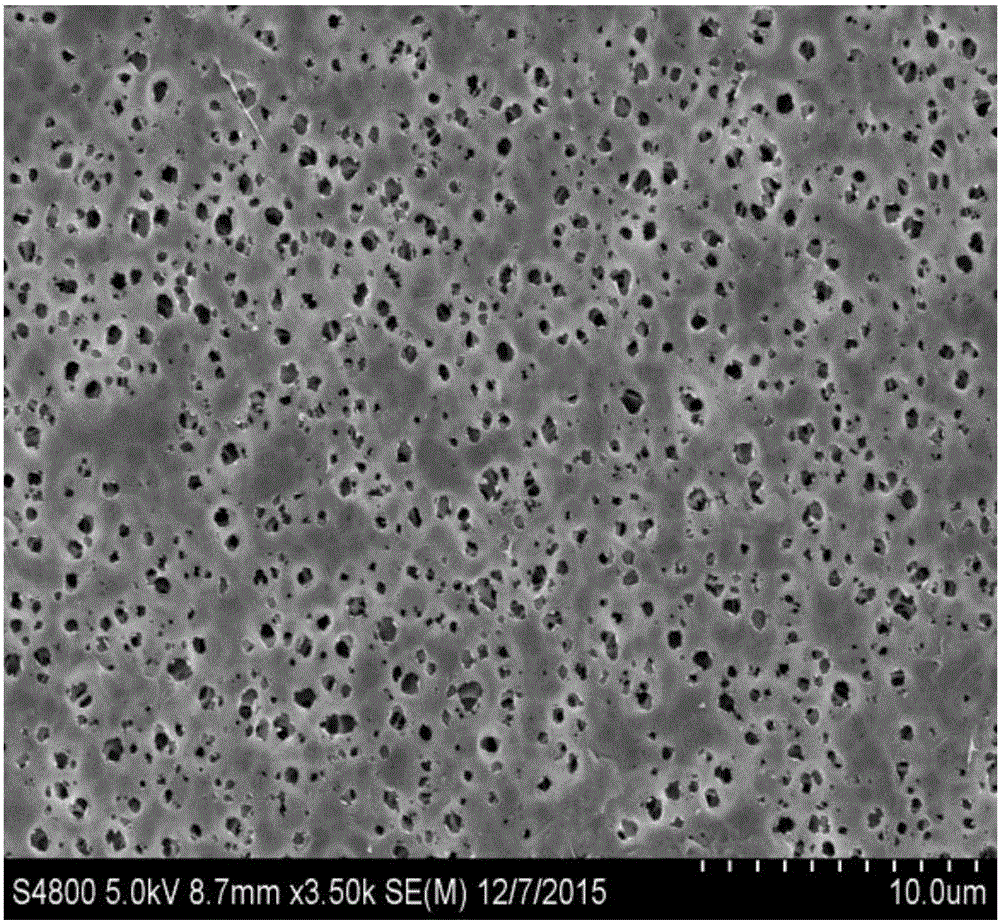

[0035] (2) The porous structure of the diaphragm is obtained by the phase separation method. Use a scraper to scrape the scraping liquid on a glass plate to form a film, then place it in ethanol at room temperature for a coagulation bath for 24 hours, then dry it at room temperature, and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com