Preparation method of spherical meso-porous molecular sieve

A mesoporous molecular sieve, spherical technology, applied in the direction of silica, silica, etc., can solve the problems of high cost, complicated synthesis steps, harsh synthesis conditions, etc., to achieve rapid synthesis, shorten synthesis time, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a preparation method of a spherical mesoporous molecular sieve, comprising: mixing a cationic surfactant, ammonia water, methyl ethyl ketone and water to obtain a mixed solution; adding tetraethyl orthosilicate (TEOS) to the mixed solution, and stirring to obtain a reaction solution; filtering the reaction solution to obtain a filtrate; and calcining the filtrate to obtain a spherical mesoporous molecular sieve.

[0033] The cationic surfactant, ammonia water, methyl ethyl ketone and water can be mixed by adding cationic surfactant to deionized water, and then adding ammonia water and methyl ethyl ketone after it is completely dissolved, or adding ammonia water and methyl ethyl ketone to water first, Afterwards, the cationic surfactant is added, as long as the components are completely dissolved to obtain a mixed solution. The concentration of ammonia water used is preferably 25-28% (volume fraction).

[0034] In order to obtain a mesoporous mole...

Embodiment 1

[0049] Weigh 0.62g CTAB and dissolve it in 30g deionized water. After it is completely dissolved, add 2.6mL ammonia water and 8.8g butanone to the solution.

[0050] Stir at room temperature for about 20 minutes, then add 2.6mLTEOS, the molar ratio of each component in the final sol is TEOS / CTAB / NH 3 / H 2 O / butanone=1:0.14:1.4:150:10.

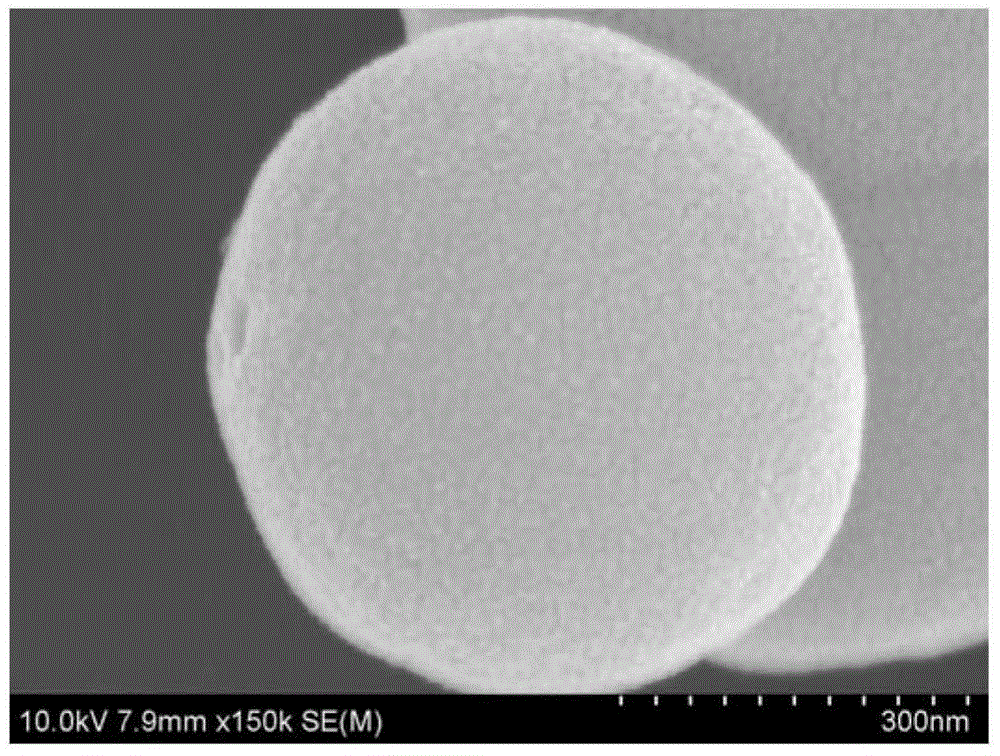

[0051] Continue to stir at room temperature for about 2 hours, then filter with suction, rinse with deionized water, dry the white precipitate in an oven at 60°C for 1 day, and bake the final powder at 500°C in a muffle furnace for 6 hours. Remove template agent, obtain the spherical MCM-41 mesoporous molecular sieve with smooth surface, its scanning electron micrograph (SEM) such as figure 1 As shown, the characteristic small-angle X-ray diffraction pattern (XRD) is as figure 2 shown.

[0052] After measurement, the total surface area of the obtained spherical MCM-41 mesoporous molecular sieve is 1055m 2 / g, the total pore volume is 0....

Embodiment 2

[0054] Weigh 0.62g CTAB and dissolve it in 30g deionized water. After it is completely dissolved, add 2.6mL ammonia water and 8.8g butanone to the solution.

[0055] Stir at room temperature for about 20 minutes, then add 2.6mLTEOS, the molar ratio of each component in the final sol is TEOS / CTAB / NH 3 / H 2 O / butanone=1:0.14:1.4:150:10.

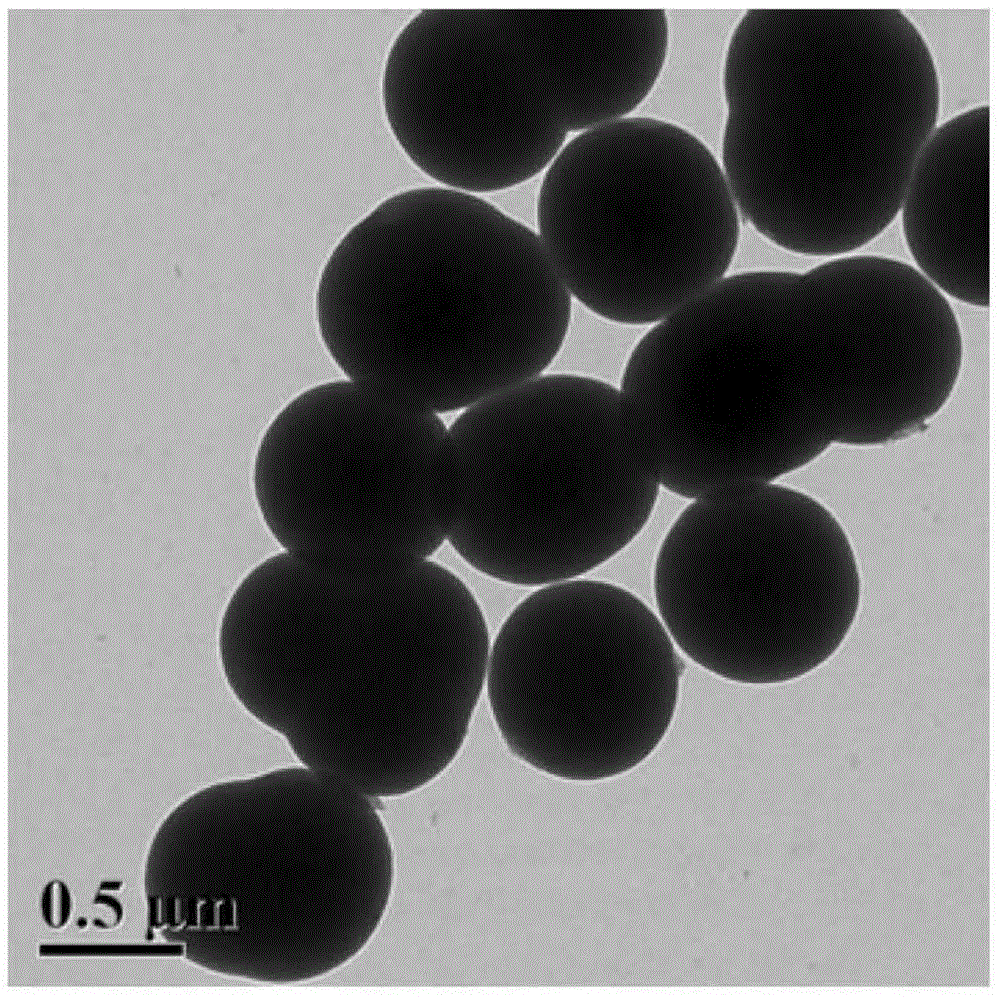

[0056] After adding TEOS and reacting for 4 hours, transfer the obtained solution to a crystallization kettle, conduct hydrothermal treatment at 85°C for 1 day, then perform suction filtration, rinse with deionized water, dry, and finally roast at 600°C , to obtain spherical MCM-41 mesoporous molecular sieves with a slightly rough surface.

[0057] After measurement, the total surface area of the obtained spherical MCM-41 mesoporous molecular sieve is 919m 2 / g, the total pore volume is 0.79cm 3 / g, the pore diameter is about 3.1nm, and the average diameter of solid spheres is about 300-400nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com