A special flame-retardant hot-melt adhesive for aluminum-plastic panels and its preparation method

A hot-melt adhesive, aluminum-plastic board technology, applied in the direction of adhesives, graft polymer adhesives, adhesive types, etc. The effect of good knot durability, high peel strength and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

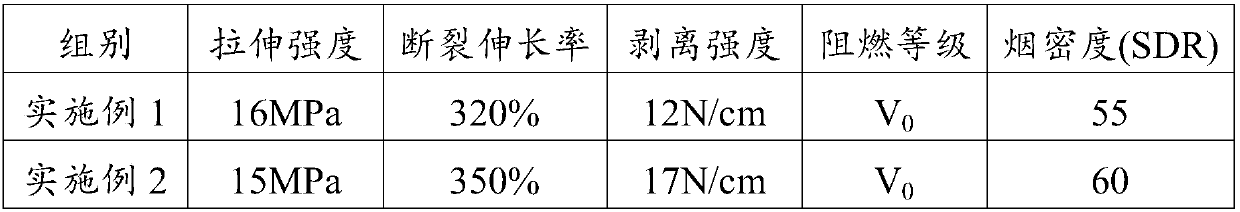

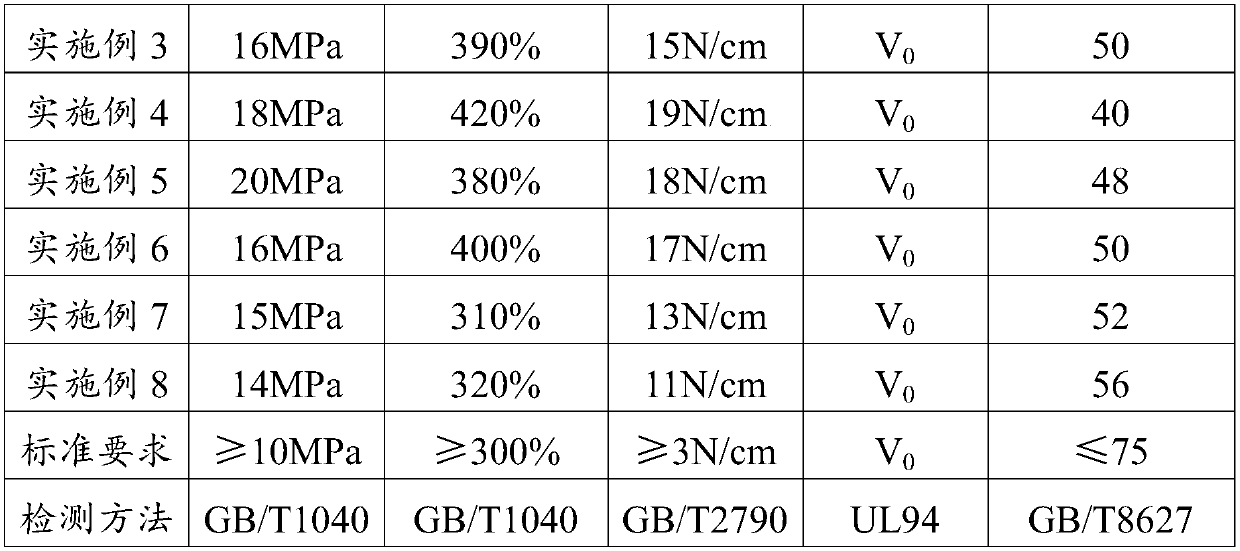

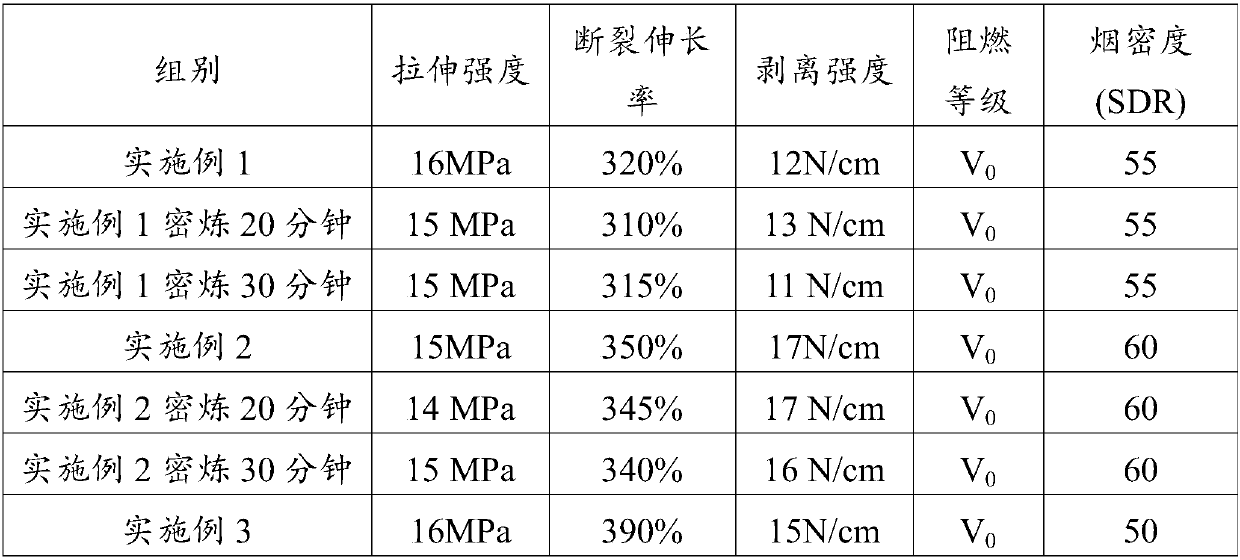

Examples

Embodiment 1

[0020] An embodiment of the flame-retardant hot-melt adhesive for aluminum-plastic panels of the present invention, the flame-retardant hot-melt adhesive for aluminum-plastic panels in this embodiment contains the following components by weight: 10 parts of polyethylene grafted maleic anhydride, melt index 40 parts of 2g / 10min high-density polyethylene, 10 parts of ethylene-octene copolymer (melt index: 0.5g / 10min), 10 parts of decabromodiphenyl ether, 5 parts of zinc borate, and 10 parts of zinc molybdate.

[0021] Wherein the polyethylene-grafted maleic anhydride is obtained by grafting maleic anhydride to high-density polyethylene with a melt index of 2 g / 10 min.

[0022] The special flame-retardant hot melt adhesive for aluminum-plastic panels described in this example is prepared by the following method:

[0023] (1) Add the above materials into a high-speed mixer and mix for 3 minutes at 55°C;

[0024] (2) Heat the mixture obtained in step (1) to 170° C. in a twin-screw...

Embodiment 2

[0026] An embodiment of the special flame-retardant hot melt adhesive for aluminum-plastic panels of the present invention, the special flame-retardant hot-melt adhesive for aluminum-plastic panels described in this embodiment comprises the following ingredients in parts by weight: 12 parts of polyethylene grafted maleic anhydride, 12 parts of melt index 35 parts of linear low density polyethylene of 5g / 10min, 9 parts of ethylene-octene copolymer (melt index of 1g / 10min), 11 parts of tetrabromobisphenol A, 6 parts of triphenyl phosphate, 9 parts of hydrotalcite .

[0027] Wherein the polyethylene-grafted maleic anhydride is obtained by grafting maleic anhydride to high-density polyethylene with a melt index of 5g / 10min.

[0028] The preparation method of the special flame-retardant hot melt adhesive for aluminum-plastic panels described in this example is the same as that in Example 1.

Embodiment 3

[0030] An embodiment of the flame-retardant hot-melt adhesive for aluminum-plastic panels of the present invention, the flame-retardant hot-melt adhesive for aluminum-plastic panels in this embodiment comprises the following components by weight: 15 parts of polyethylene grafted maleic anhydride, 15 parts of melt index 30 parts of 6g / 10min low-density polyethylene, 8 parts of ethylene-octene copolymer (melt index: 10g / 10min), 12 parts of decabromodiphenylethane, 7 parts of ammonium polyphosphate, and 8 parts of molybdenum trioxide.

[0031] Wherein the polyethylene-grafted maleic anhydride is obtained by grafting maleic anhydride to high-density polyethylene with a melt index of 8g / 10min.

[0032] The preparation method of the special flame-retardant hot melt adhesive for aluminum-plastic panels described in this example is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com