Fast setting epoxy system for bonding engineering plastic and preparing method of fast setting epoxy system

A fast-curing, engineering plastics technology, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problem of moisture sensitivity of polyurethane two-component structural adhesive, pungent taste of acrylic two-component adhesive, and bonding Poor strength stability and other problems, to improve the anti-peel strength, shorten the curing time, and reduce the effect of irritating odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A fast-curing epoxy system for bonding engineering plastics, which includes component A and component B, and the mass ratio of component A to component B is 2:1;

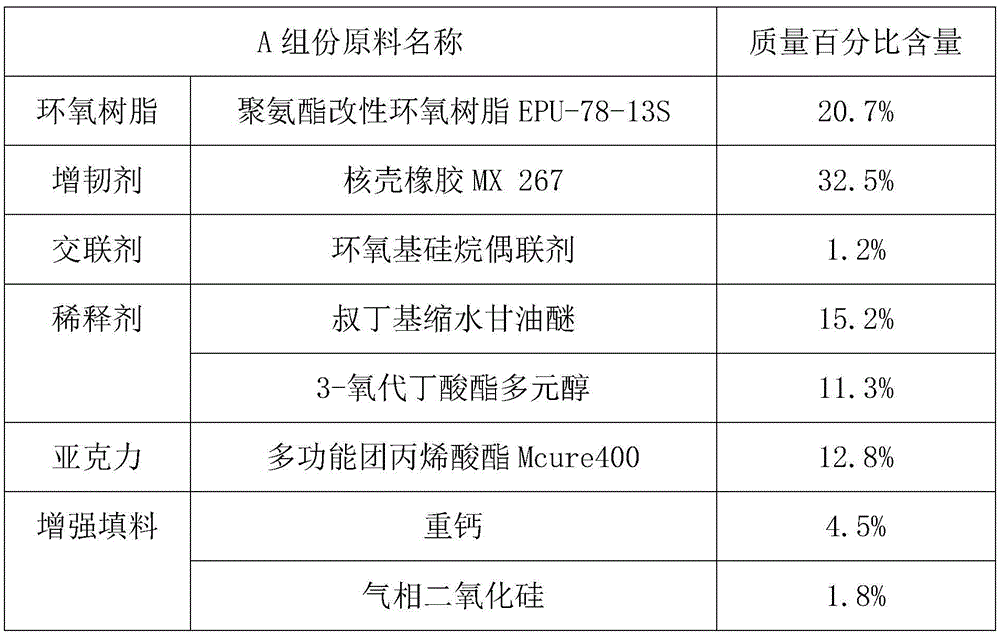

[0034] Wherein the mass percentage content of each raw material in A component is:

[0035]

[0036] The mass percentage content of each raw material in component B is:

[0037]

[0038] A kind of above-mentioned preparation method for the fast curing epoxy system of bonding engineering plastics, comprises the following steps:

[0039] (a) Weigh according to the mass percentage content of epoxy resin, toughening agent, crosslinking agent, diluent, acrylic and polyurethane in component A, put it into a plastic tank, and stir evenly on a stirring defoaming machine;

[0040] (b) Add heavy calcium powder, stir and mix evenly, then add fumed silica, stir and mix evenly to obtain component A;

[0041] (c) According to the mass percentage of aliphatic amine polyamine in component B, after heating the weighed...

Embodiment 2

[0045] A fast-curing epoxy system for bonding engineering plastics, which includes component A and component B, and the mass ratio of component A to component B is 2:1;

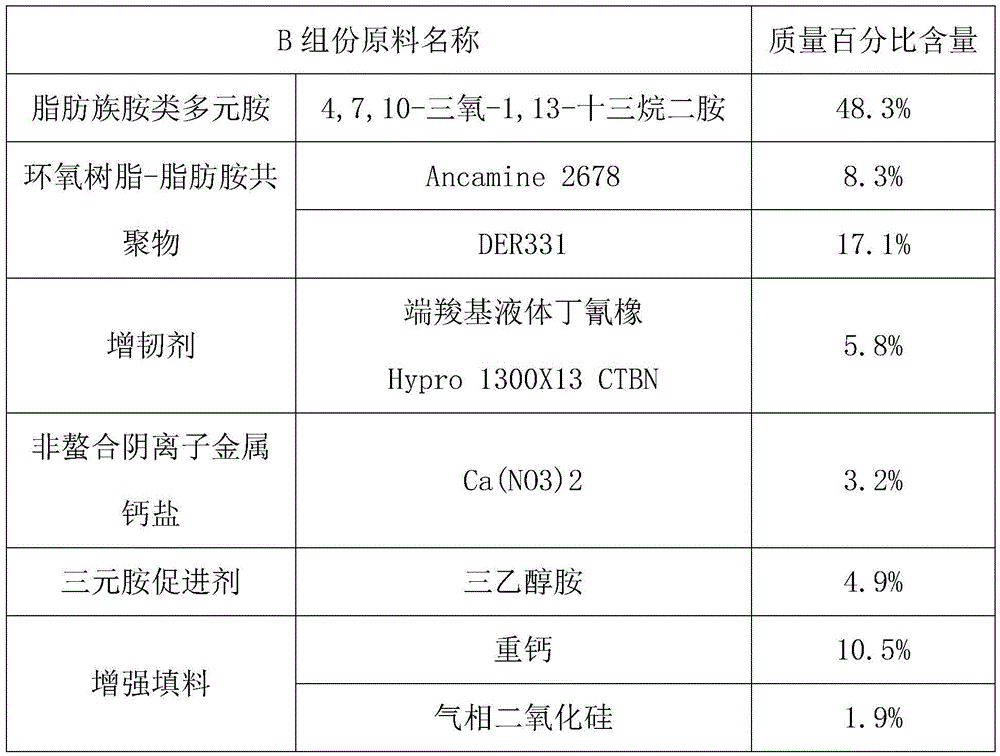

[0046] Wherein the mass percentage content of each raw material in A component is:

[0047]

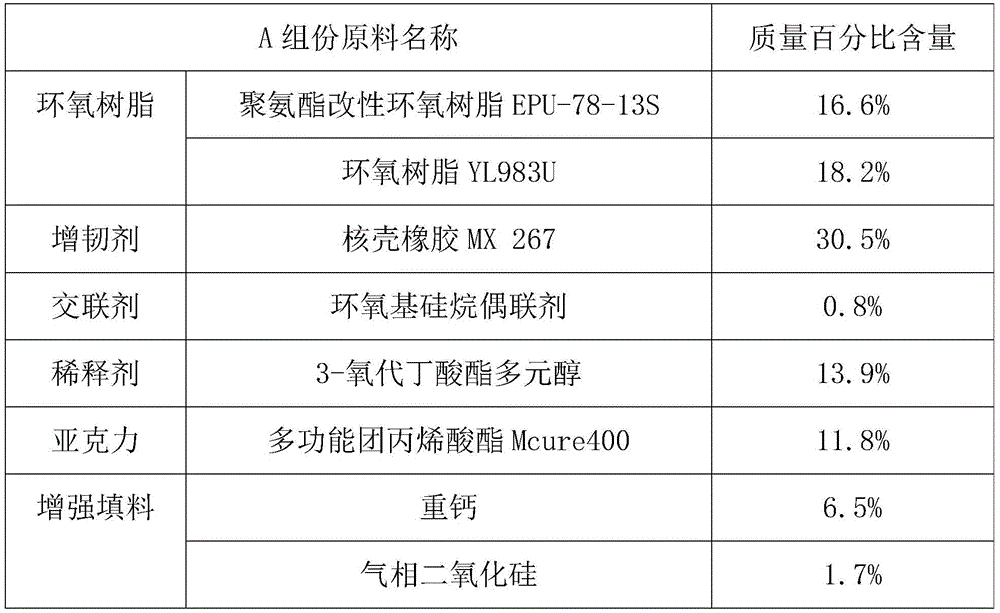

[0048] The mass percentage content of each raw material in component B is:

[0049]

[0050]

[0051] The preparation method of the above-mentioned fast-curing epoxy system for bonding engineering plastics is the same as that described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com