Method for forming reinforced-phase-strengthened composite welding seam structural material by regulating

A technology of composite welds and structural materials, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of complicated metal surface cleaning process, welding deformation, cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for forming a reinforcing phase reinforced composite weld structure material through regulation and control, the steps are as follows:

[0029] 1) Clean the aluminum and steel surfaces to be welded to remove oxide films, stains and grease, and dry them for later use;

[0030] 2) Grinding, polishing, and cleaning the surface of the silicon particle-reinforced composite material to remove oxide films, stains and grease, and drying for later use;

[0031] 3) Grinding, polishing, and cleaning the surface of the solder Sn-9Zn, removing oxide film, stains and grease, and drying for later use;

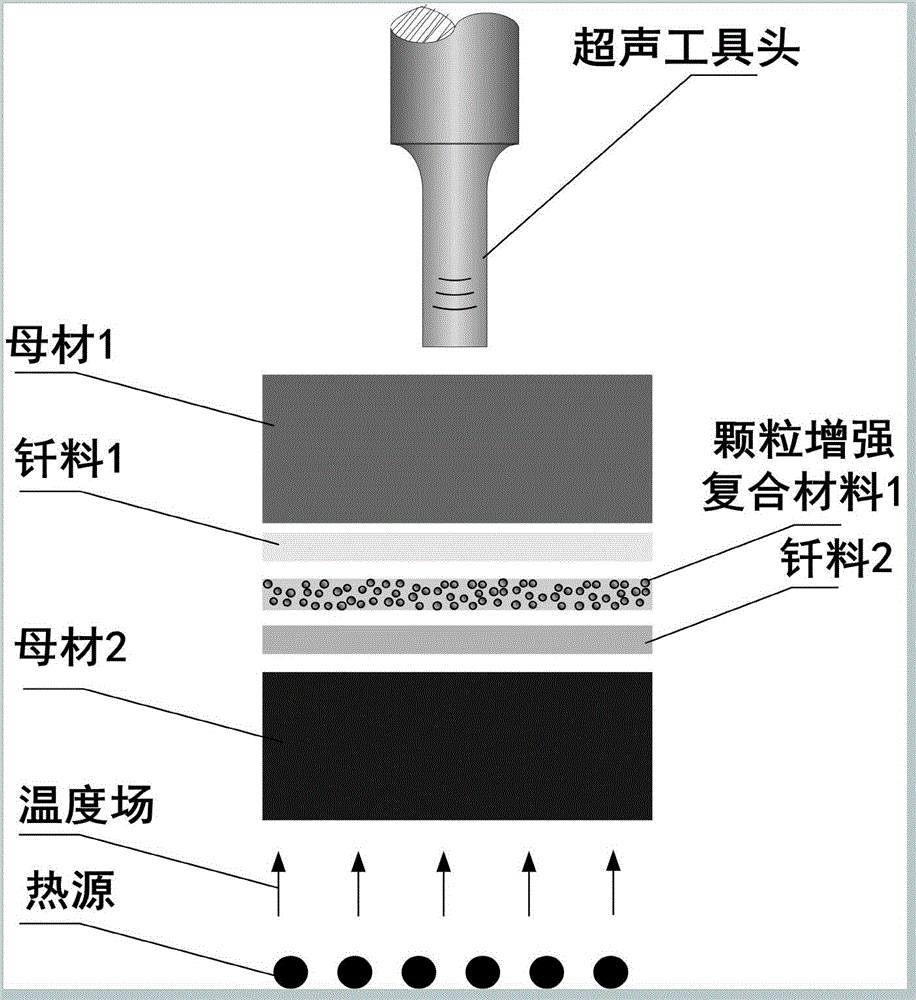

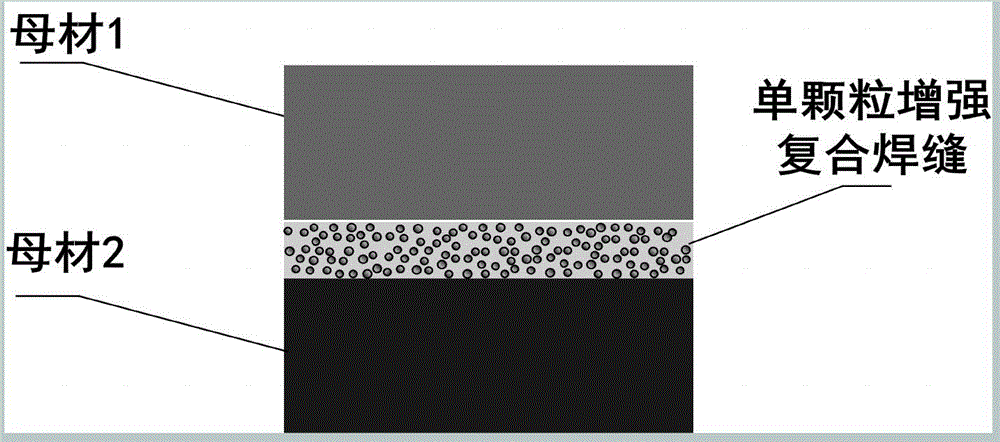

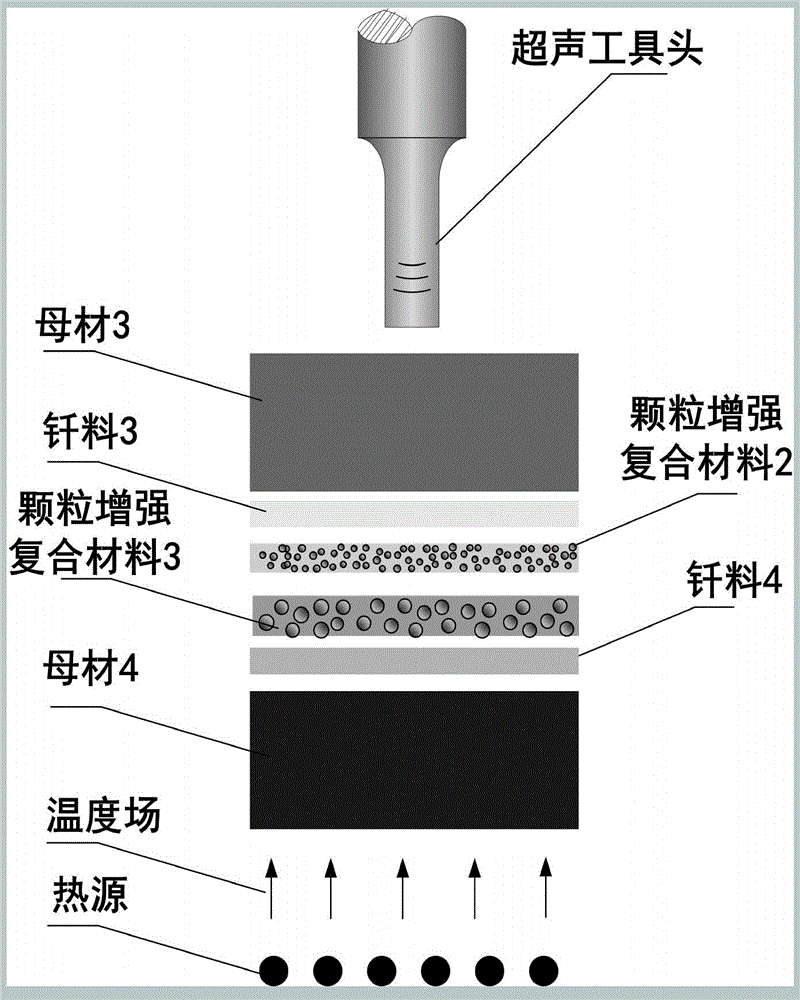

[0032] 4) The base metal to be welded, the solder metal alloy and the composite material after the above treatment are assembled according to the structure of "aluminum / brazing material / composite material / brazing material / steel", such as figure 1 Then put it into the ultrasonic-assisted welding device, heat it to 260°C and keep it warm for 60 minutes, and apply ultrasonic wav...

Embodiment 2

[0035] A method for forming a reinforcing phase-strengthened composite weld structure material through regulation and control, the steps of which are basically the same as those in Embodiment 1, except that the base materials used are titanium and alumina ceramics.

Embodiment 3

[0037] A method for forming a reinforcing phase reinforced composite weld structure material through regulation and control, the steps are basically the same as in Example 1, the difference is that the solder used is a tin-based, zinc-based, silver-based, copper-based or aluminum-based alloy Solder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com