Alloy design method for reducing directionally-solidified titanium aluminum alloy interface reaction

A technology of directional solidification, titanium-aluminum alloy, used in self-solidification methods, chemical instruments and methods, single crystal growth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

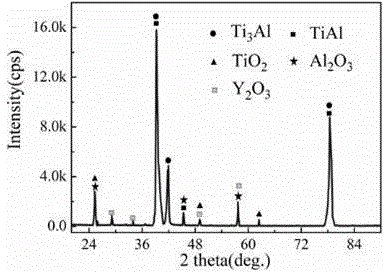

[0020] A method to measure the reaction degree of the interface between the titanium aluminum alloy and the casting coating.

[0021] (1) Master ingot casting. The experimental raw materials are sponge Ti, Al powder, Cr powder, AlV and AlNb particles (granular 325 mesh). The proportion of ingredients is selected according to the parameters of the composition part. The final proportion obtained is shown in Table 1. The experiment uses a vertical centrifugal vacuum induction melting and casting furnace for casting. The vacuum in the furnace is maintained at about 0.5Pa and then protected by Ar gas. After repeated three times, the vacuum is maintained at about 0.08Pa, and the pressure relief rate is <0.1Pa / mm. After melting and casting, put the ingot upside down and cast it again, repeat three times to make the ingot element distribution evenly, and take points to check the composition distribution. The ingots that meet the requirements are used as master ingots for directional soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com