Uniformity control method for growing carbon nano tubes in titanium alloy shading cover

A carbon nanotube and control method technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problems of poor metal valence bond state and carbon wettability, low melting point, complex structure, etc. Achieve the effect of not easy to fall off as a whole, increase the contact area, and reduce the growth temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

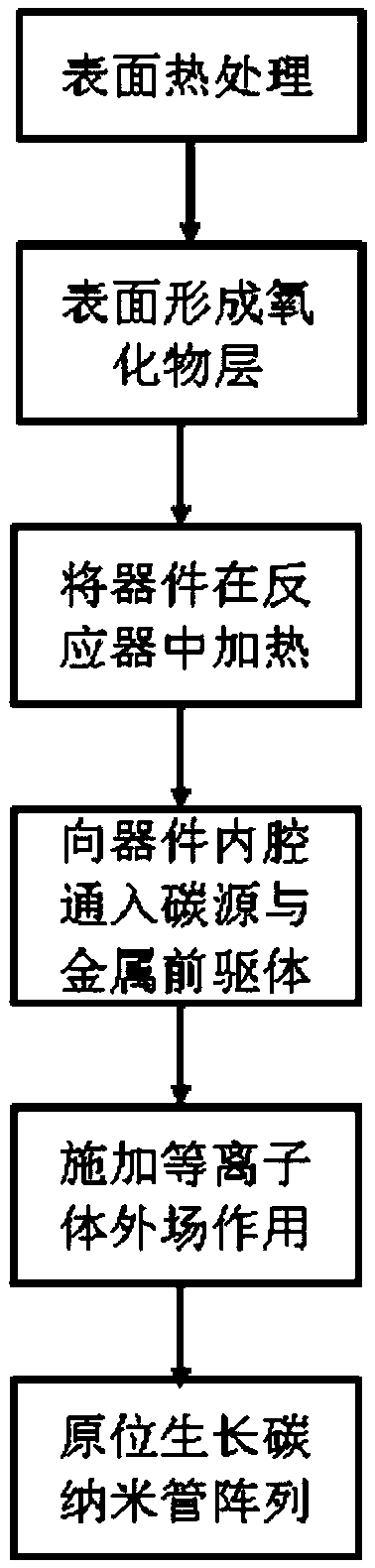

Method used

Image

Examples

Embodiment 1

[0034] The titanium alloy light shield (the inner surface area is 10000 square millimeters) is heat-treated for 0.5 hours in process gas (ethanol 50% (volume fraction), hydrogen (30%), nitrogen (20%)) at 700 ° C, on its surface Regular carbon-titanium compound-containing protrusions are formed. Each protrusion has a diameter of 0.01 μm and a height of 0.3 μm. The density is 100 / square micron. Then heat treatment in oxygen at 300°C for 3 hours.

[0035] Immerse the surface-treated titanium alloy light shield in tetraethyl orthosilicate for 0.5 hours. Then, 0.1 liter of water was directed into the inner cavity of the titanium alloy light shield, heated to 100°C, and a silicon oxide layer with a thickness of 0.1 micron was formed on the surface of the inner cavity of the titanium alloy light shield.

[0036] Put the titanium alloy shading cover after the above treatment into a large cavity reactor (3 times the diameter of the titanium alloy shading cover), hang it in the air all...

Embodiment 2

[0039] The titanium alloy light shield (with an inner surface area of 1000 square millimeters) was heat-treated at 700°C for 3 hours in a process gas (ethanol 90% (volume fraction), hydrogen (5%), argon (5%)), and on its surface Regular carbon-titanium compound-containing protrusions are formed. Each protrusion is 0.1 μm in diameter and 2 μm in height. The density is 200 / square micron. Then heat treatment in oxygen at 500°C for 0.5 hours.

[0040] Immerse the titanium alloy light shield with the preliminary surface treatment in ethyl orthotitanate for 2 hours. Then 1 liter of water was directed into the inner cavity of the titanium alloy light shield, heated to 150° C., and a titanium oxide layer with a thickness of 5 microns was formed on the surface of the inner cavity of the titanium alloy light shield.

[0041] Put the titanium alloy shading cover after the above treatment into a large cavity reactor (5 times the diameter of the titanium alloy shading cover), hang it ...

Embodiment 3

[0044] The titanium alloy light shield (with an inner surface area of 5000 square millimeters) was heat-treated at 700°C for 3 hours in a process gas (ethanol 70% (volume fraction), hydrogen (25%), nitrogen (5%)), and on its surface Regular carbon-titanium compound-containing protrusions are formed. Each protrusion has a diameter of 0.3 microns and a height of 10 microns. The density is 150 / square micron. Then heat treatment at 500°C for 0.5 hours in air.

[0045] Immerse the surface-treated titanium alloy gobo in ethyl titanate for about 1 hour. Then, 1 liter of water vapor was directionally introduced into the inner cavity of the titanium alloy light shield, heated to 150°C, and a titanium oxide layer with a thickness of 5 microns was formed on the surface of the inner cavity of the titanium alloy light shield.

[0046] Put the titanium alloy shading cover after the above treatment into a large cavity reactor (5 times the diameter of the titanium alloy shading cover), h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com