Surface nickel coating grain size regulating method capable of improving corrosion resistance

A technology of corrosion resistance and nickel coating, which is applied in the field of nickel coating grain size control and Ni coating to improve the corrosion resistance of alloys. control and other problems, to achieve the effect of dense coating, high hardness and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This example relates to an electroplating method for obtaining a micron-scale nickel coating by direct current electroplating. The method includes the following steps:

[0041] Step 1: The surface of the nickel-aluminum-bronze alloy is polished by 180#—400#—800#—1200# water sandpaper machine in turn, and then in the configured degreasing liquid (including 30g / LNaOH, 35g / LNa 2 CO 3 , 40g / LNa 3 PO 4 ) Keep at 70°C for 1 min, remove residual grease, rinse with water, and set aside;

[0042] Step 2: Put the processed nickel aluminum bronze at 100mL / LH 2 SO 4 After pickling and activation, rinse with water and dry with cold air and immediately place it in the following plating solution:

[0043]

[0044] Heat the electrolyte temperature to 50±1℃; adjust its pH value to 4.0±0.2 with ammonia water; Direct current The current density is 5A / dm 2 ; The plating time is 60min;

[0045] Step 3: Take out the electroplated nickel-aluminum bronze alloy, rinse it with deionized water, and dry i...

Embodiment 2

[0048] This example relates to an electroplating method for obtaining a submicron nickel coating by pulse electroplating. The method includes the following steps:

[0049] Step 1: The surface of the nickel-aluminum-bronze alloy is polished by 180#—400#—800#—1200# water sandpaper machine in turn, and then in the configured degreasing liquid (including 30g / LNaOH, 35g / LNa 2 CO 3 , 40g / LNa 3 PO 4 ) Keep at 70°C for 1 min, remove residual grease, rinse with water, and set aside;

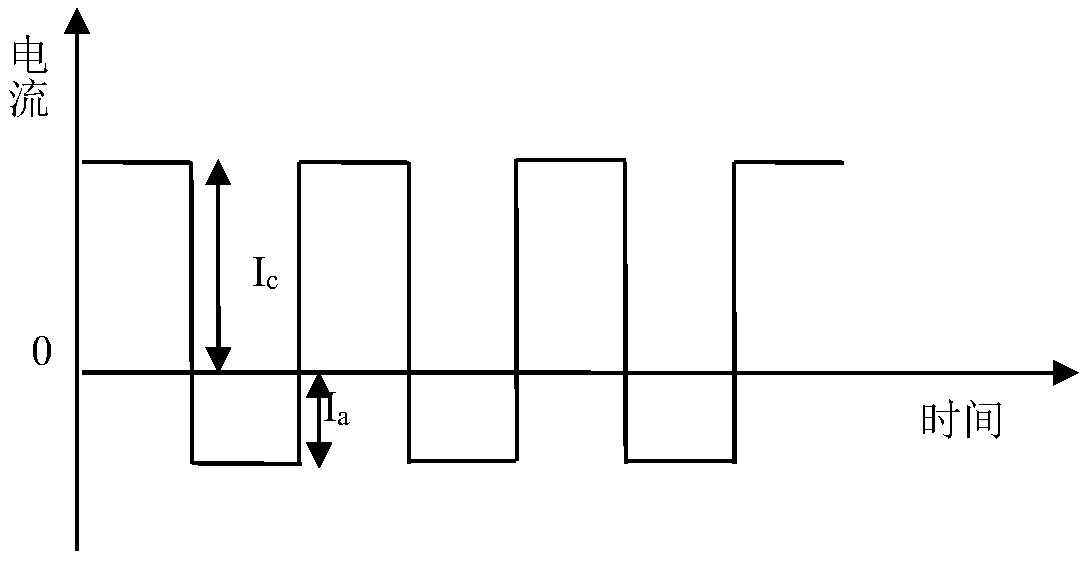

[0050] Step 2: Use 100mL / LH for the processed nickel aluminum bronze alloy 2 SO 4 After pickling and activation, rinse with water and dry it with cold air and immediately place it in the plating solution in Example 1. Heat the electrolyte temperature to 50±1℃; adjust the pH value to 4.0±0.2 with ammonia water; the applied bidirectional pulse current waveform Picture like figure 2 As shown, the forward pulse current density Ic is 2A / dm 2 , The reverse pulse current density Ia is 0.5A / dm 2 , The pulse frequency ...

Embodiment 3

[0054] This example relates to an electroplating method for obtaining a nano-scale nickel coating by pulse electroplating. The method includes the following steps:

[0055] Step 1: The surface of the nickel-aluminum-bronze alloy is mechanically polished with 180#—400#—800#—1200# water sandpaper in turn, and then 70% in the configured degreasing liquid (containing 30g / LNaOH, 35g / LNa2CO3, 40g / LNa3PO4) Keep constant temperature at ℃ for 1 min, remove residual grease, rinse with water, and then set aside;

[0056] Step 2: The treated nickel-aluminum bronze was pickled and activated with 100mL / LH2SO4, rinsed with water and dried by cold air, and immediately placed in the plating solution in Example 1. Heat the electrolyte temperature to 50±1°C; adjust it with ammonia The pH value is 4.0±0.2; the waveform of the applied pulse current is as follows Figure 4 As shown, the current density Ip is 30A / dm 2 , The pulse frequency is 500Hz, the power-on time t is 0.4ms, the power-off time t is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com