Preparation and application of linear biodegradable polyester elastomer with controllable elasticity and shape memory effect

A technology of memory effect and degradation of polyester, used in prosthesis, medical science, pharmaceutical formulation, etc., can solve the problems of low shape recovery rate, gap in elasticity, too hard, etc., and achieve the effect of improving viscoelasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

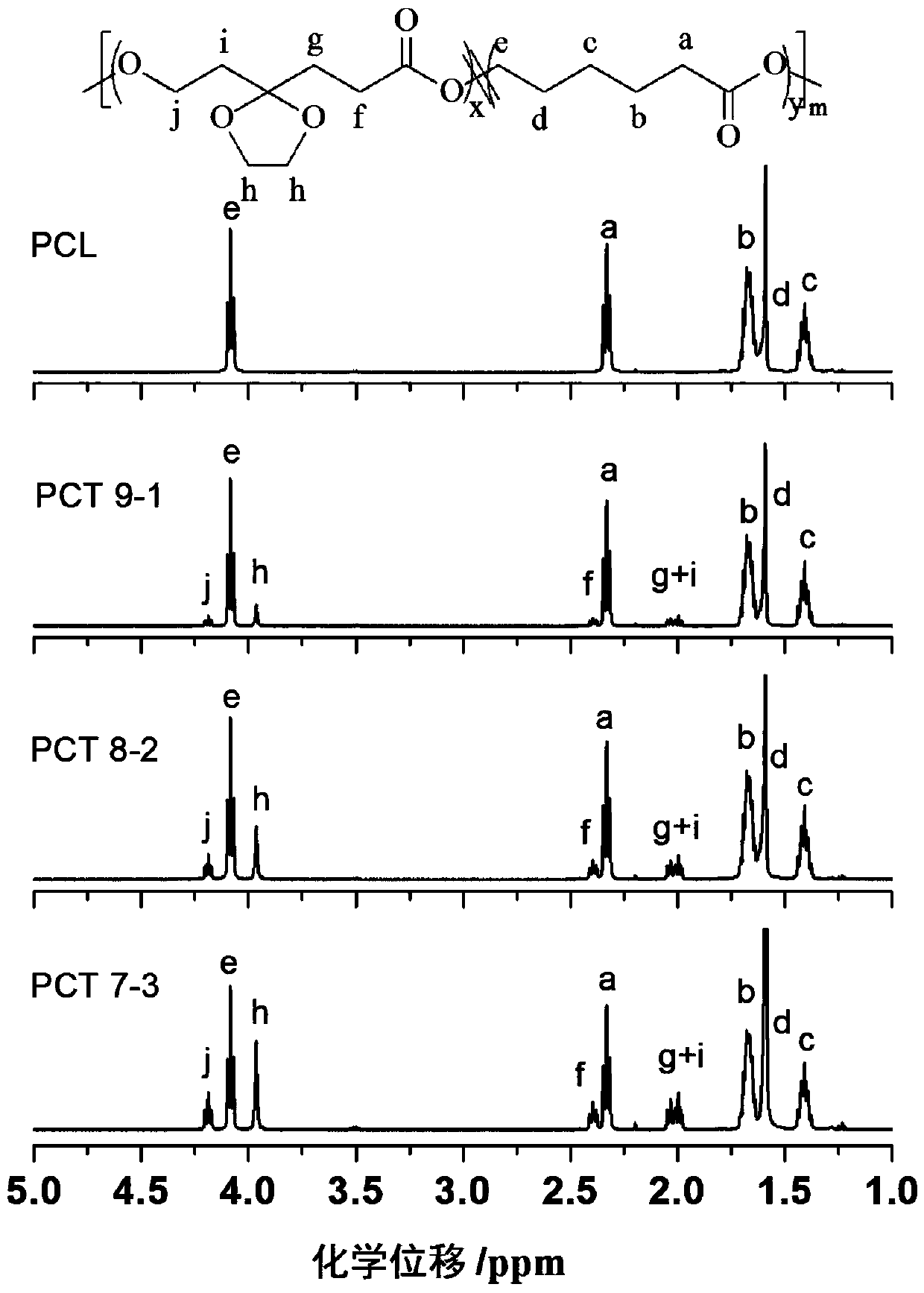

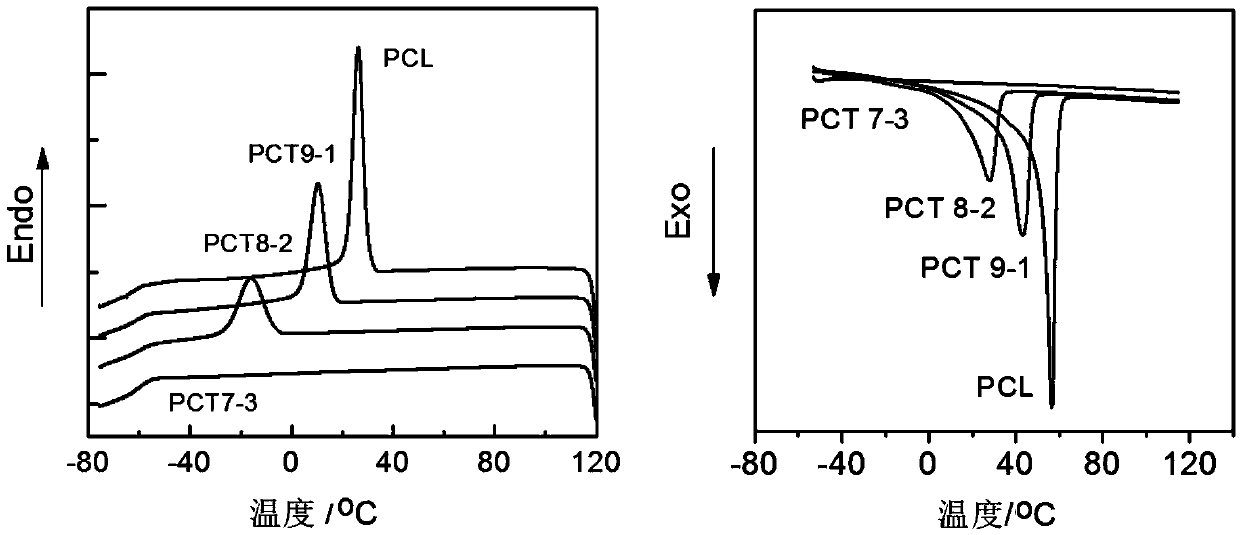

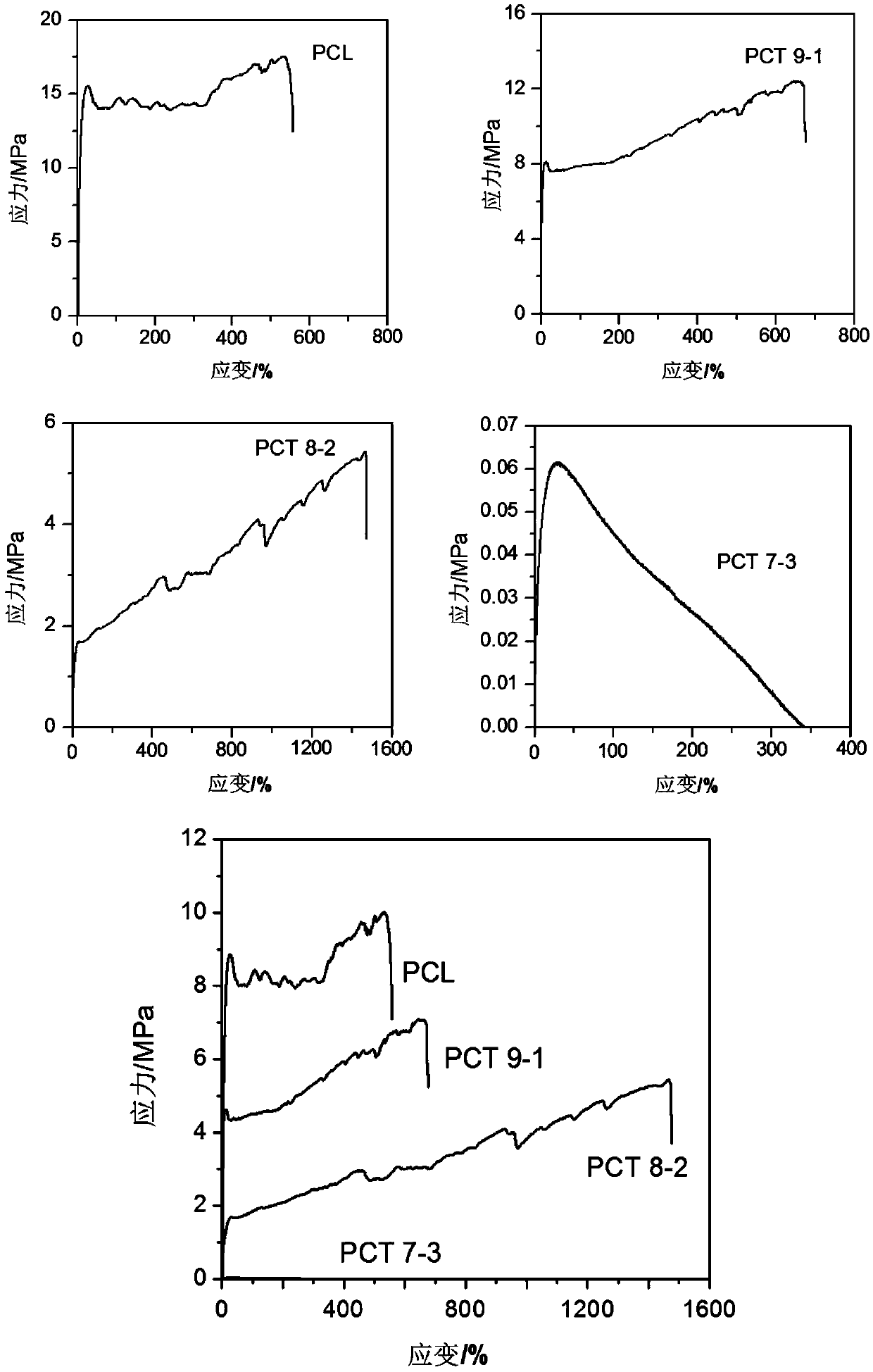

[0044] Example 1: Preparation of linear degradable polyester elastomer with adjustable elasticity and shape memory effect

[0045] Take 9.0 g of ε-caprolactone and 1.0 g of 4-(ethylene glycol ketal)-ε-caprolactone, mix the above-mentioned raw materials evenly, and add 2 mg of stannous isooctanoate under the protection of an inert atmosphere, and then Under low temperature (less than 50Pa) at 115°C for 24 hours. After the reaction is completed, use dichloromethane / ethanol system (volume ratio 1:2) to carry out sedimentation purification to obtain a copolymer, which is marked as PCT9-1. The number average molecular weight measured by GPC is 104,000, and the weight average molecular weight is 19.3 Wan, the Young's modulus of the film cast from dichloromethane is 146.2MPa, the elongation at break is 676.8%, and the tensile strength is 9.79MPa.

Embodiment 2

[0046] Example 2: Preparation of linear degradable polyester elastomer with adjustable elasticity and shape memory effect

[0047] Take 8.0 g of ε-caprolactone and 2.0 g of 4-(ethylene glycol ketal)-ε-caprolactone, mix the above raw materials evenly, and add 2 mg of stannous isooctanoate under the protection of an inert atmosphere, and then Under low temperature (less than 50Pa) at 115°C for 24 hours. After the reaction was completed, the dichloromethane / ethanol system (volume ratio 1:2) was used for sedimentation and purification to obtain a copolymer marked as PCT8-2. The number average molecular weight measured by GPC was 139,000, and the weight average molecular weight was 26.9 Wan, the Young's modulus of the film cast from dichloromethane is 18.3MPa, the elongation at break is 1663.3%, and the tensile strength is 11.5MPa.

Embodiment 3

[0048] Example 3: Preparation of linear degradable polyester elastomer with adjustable elasticity and shape memory effect

[0049] Take 7.0 g of ε-caprolactone and 3.0 g of 4-(ethylene glycol ketal)-ε-caprolactone, mix the above-mentioned raw materials evenly, and add 2 mg of stannous isooctanoate under the protection of an inert atmosphere, and then Under low temperature (less than 50Pa) at 115°C for 24 hours. After the reaction is completed, use dichloromethane / ethanol system (volume ratio 1:2) to carry out sedimentation purification to obtain a copolymer, which is marked as PCT7-3. The number average molecular weight measured by GPC is 130,000, and the weight average molecular weight is 22.4 Wan, the Young's modulus of the film cast from dichloromethane is 1.2MPa, the elongation at break is 244.7%, and the tensile strength is 0.05MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com