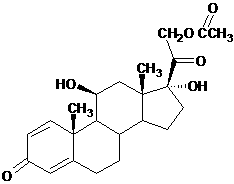

Prednisolone acetate preparation method

A prednisolone acetate, reaction technology, applied in the direction of steroids, organic chemistry, etc., can solve the problems of high production cost, unfavorable production, and potential safety hazards of prednisolone acetate, so as to shorten the production cycle and reduce the Solubility, effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Add 750ml of acetone, 30g of prednisolone acetate intermediate reduction, 12g of sodium acetate, 50ml of acetic anhydride, and 8ml of acetic acid into the reaction flask in sequence, and heat up and reflux for 4 hours. TLC showed that the reaction was complete. Most of the solvent was recovered by atmospheric distillation, and then evaporated to dryness under reduced pressure, cooled to below 5°C, stirred for 30 minutes, left to stand for more than 2 hours, filtered, and dried to obtain 32.0 g of esterified product.

[0040] Put 30g of the esterified product into a solution prepared by 150ml of 36% hydrochloric acid, 240ml of water, and 15ml of chloroform, and stir at 25°C to 30°C for 30 minutes to dissolve. Cool down, and add dropwise a solution prepared from 30 g of sodium nitrite and 1050 ml of water at 18°C to 22°C. After the addition was complete, the reaction was continued at 18°C to 22°C for 3 hours. TLC showed that the reaction was complete, lower the tempe...

Embodiment 2

[0042] Add 750ml of acetone, 30g of prednisolone acetate intermediate reduction, 15g of potassium acetate, 51ml of acetic anhydride, and 9ml of acetic acid into the reaction flask in sequence, and heat up and reflux for 4.5 hours. TLC showed that the reaction was complete, most of the solvent was recovered by atmospheric distillation, and then the solvent was evaporated under reduced pressure, cooled to below 5°C, stirred for 30 minutes, left to stand for more than 2 hours, filtered, and dried to obtain 31.9g of esterified product.

[0043] Put 30g of the esterified product into a solution prepared by 150ml of 36% hydrochloric acid, 240ml of water, and 15ml of chloroform, and stir at 25°C to 30°C for 30 minutes to dissolve. Cool down, and add dropwise a solution prepared from 30 g of sodium nitrite and 1050 ml of water at 18°C to 22°C. After the addition was complete, the reaction was continued at 18°C to 22°C for 3 hours. TLC showed that the reaction was complete, lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com