Fin field-effect transistor formation method

A fin field effect transistor and fin technology, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of poor quality of stress layer and low electrical performance of fin field effect transistors, so as to achieve less etching damage and improve Electrical properties, highly selective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] It can be known from the background technology that the quality of the stress layer formed in the prior art is poor, which leads to poor performance of the fin-type field effect transistor.

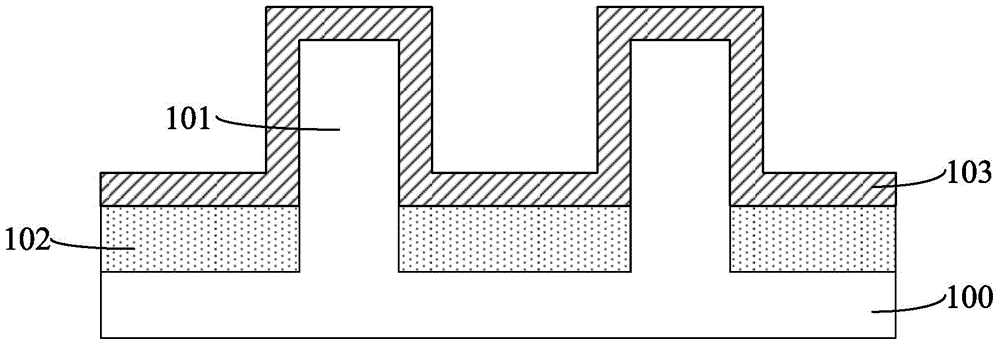

[0038] Please refer to figure 1 In one embodiment, a substrate 100 having fins 101 is provided, and an isolation layer 102 is formed on the surface of the substrate 100 between adjacent fins 101, and the isolation layer 102 covers part of the sidewall surface of the fin 101 , And the top surface of the isolation layer 102 is lower than the top surface of the fin 101; a barrier layer 103 covering the surface of the isolation layer 102, the sidewalls and the top surface of the fin 101 is formed.

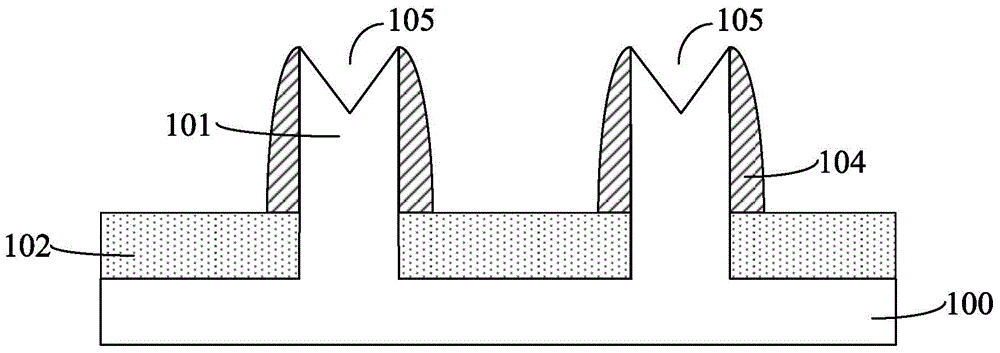

[0039] Please refer to figure 2 , Using a maskless etching process to etch and remove the barrier layer 103 located on the top surface of the fin 101 and the surface of the isolation layer 102 (please refer to figure 1 ), forming a sidewall layer 104 on the sidewall surface of the fin 101, exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com