W-ti sputtering target

A sputtering target and target surface technology, applied in sputtering coating, vacuum evaporation coating, coating and other directions, can solve the problems of etching speed variation, inability to perform uniform etching, etc., and achieve the effect of small etching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

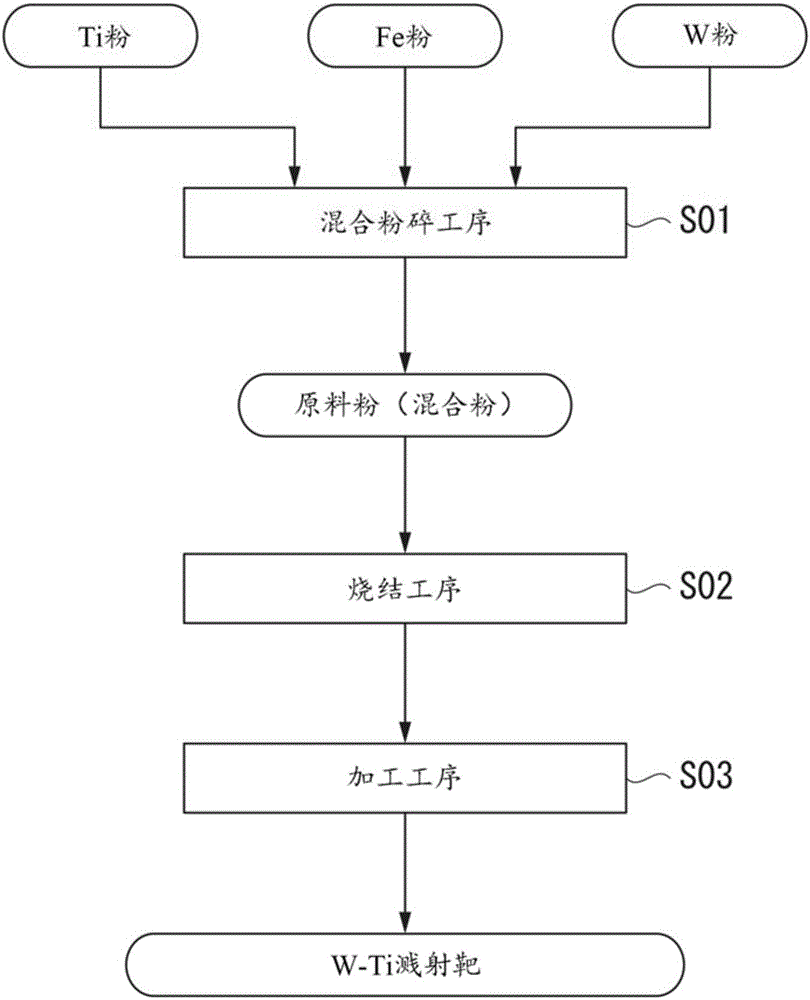

Method used

Image

Examples

Embodiment

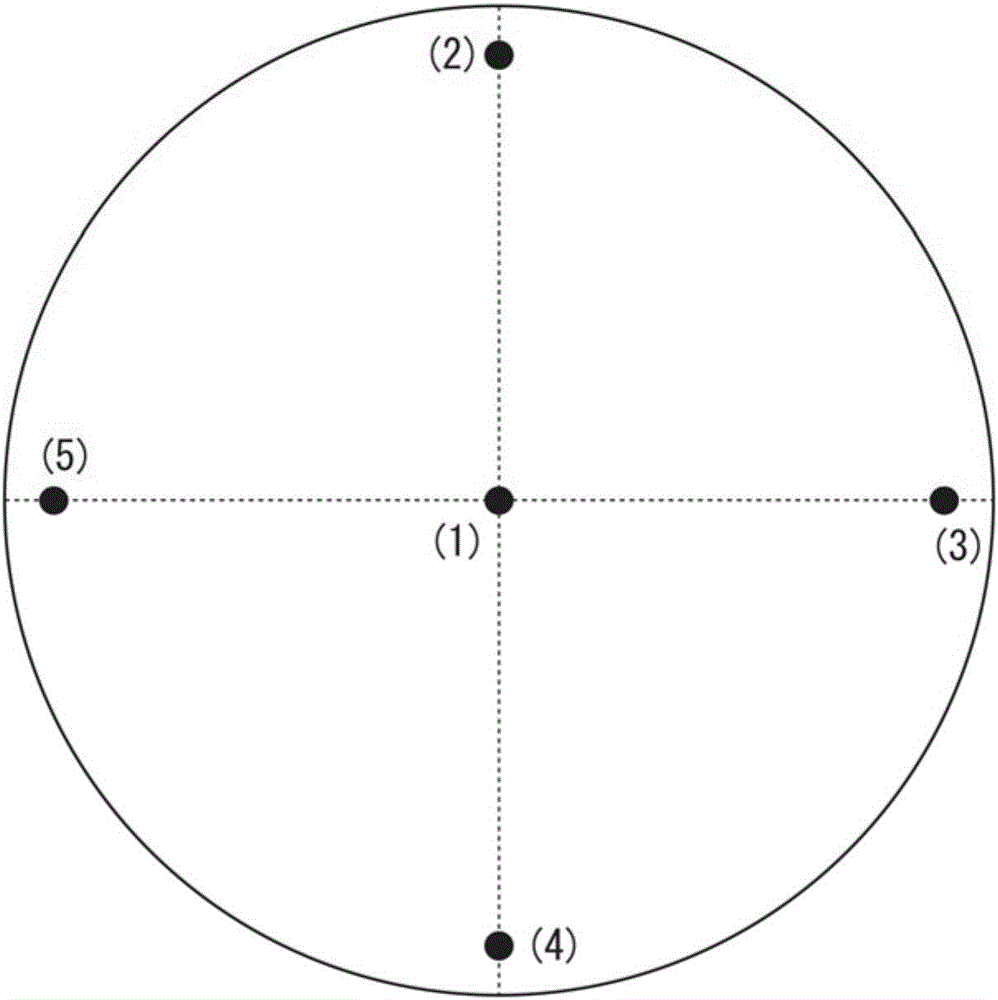

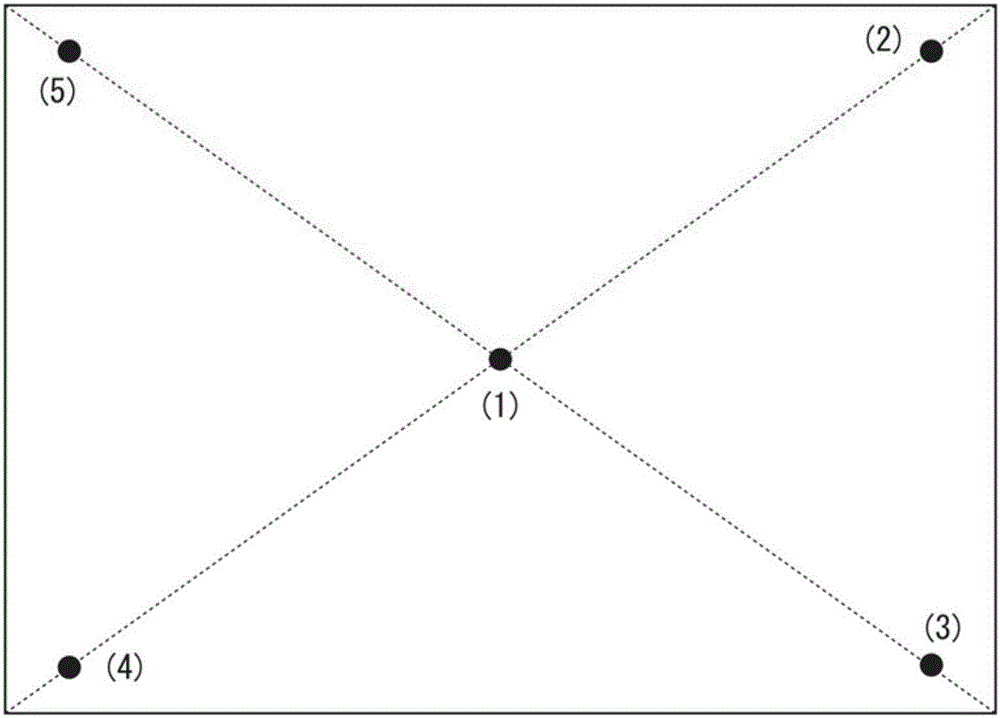

[0067] Hereinafter, the result of the evaluation test which evaluated the function effect of the W-Ti sputtering target concerning this invention is demonstrated.

[0068]

[0069] As raw material powders, Ti powder with a purity of 99.999% by mass and an average particle size of 15 μm, W powder with a purity of 99.999% by mass and an average particle size of 1 μm, and Fe powder with a purity of 99.999% by mass and an average particle size of 100 μm were prepared. And Ti powder, Fe powder, and W powder were weighed so that it might become the composition shown in Table 1.

[0070] Among the weighed Ti powder, Fe powder, and W powder, the W powder and Fe powder were put into an attritor device (MA1D of NIPPON COKE & ENGINEERING CO., LTD.) together with cemented carbide balls with a diameter of about 5 mm, and the Mixing and pulverization was performed for 1 hour under an Ar atmosphere at a rotational speed of 300 ppm. In addition, in order to prevent the mixing of impurities...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com