High-precision antiseptic wear-resisting oil tube and manufacturing method thereof

A technology of anti-corrosion and wear-resisting and production methods, which is applied in the direction of pipeline anti-corrosion/rust protection, pipes, rigid pipes, etc., and can solve the problems of inability to control the dimensional accuracy of steel pipes, anti-corrosion coatings without wear resistance, and reduced anti-rust performance. Achieve reliable welding processability, high anti-corrosion performance, and improve the effect of corrosion resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

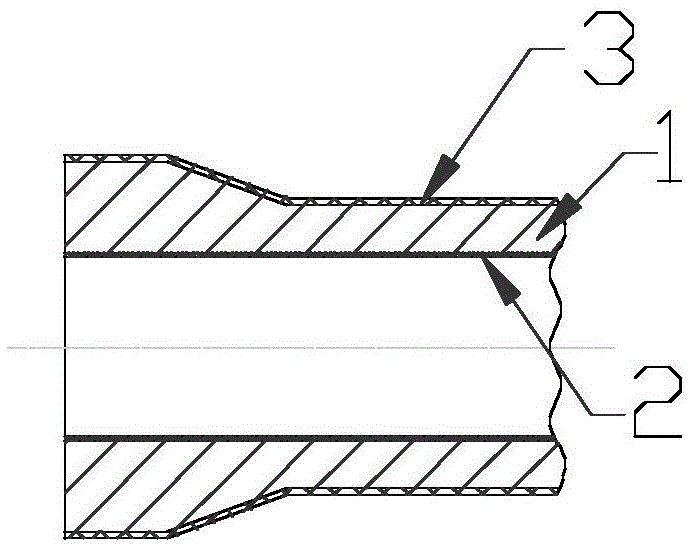

[0031] like figure 1 As shown, a high-precision anti-corrosion and wear-resistant oil pipe includes a pipe body 1, an inner coating 2 is provided on the inner wall of the pipe body 1, an outer coating 3 is provided on the outer wall of the pipe body 1, and the inner coating 2 is heat Zinc plating or electroless nickel-phosphorus alloy plating, the outer coating 3 is electrochrome plating, nickel-chromium composite coating or electroless nickel-phosphorus alloy plating. Wherein, the wall thickness of one end of the pipe body 1 is thicker than that of the other end, that is, the pipe body 1 has a shape characteristic of thickening the end. Of course, the end of the pipe body 1 may not be thickened, and it can be manufactured according to specific requirements.

[0032] When in use, the corrosion resistance and wear resistance of the inner and outer surfaces of the steel pip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com