Method for green synthesis of nanometer zero-valent iron-copper bi-metal material and application

A technology of nano-zero-valent iron and green synthesis, which is applied in the direction of nanotechnology, chemical instruments and methods, and restoration of polluted soil, etc., can solve the problems of small investment in equipment, toxic and side effects of reducing agents, etc., to improve stability and reduce six The effect of chromium content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

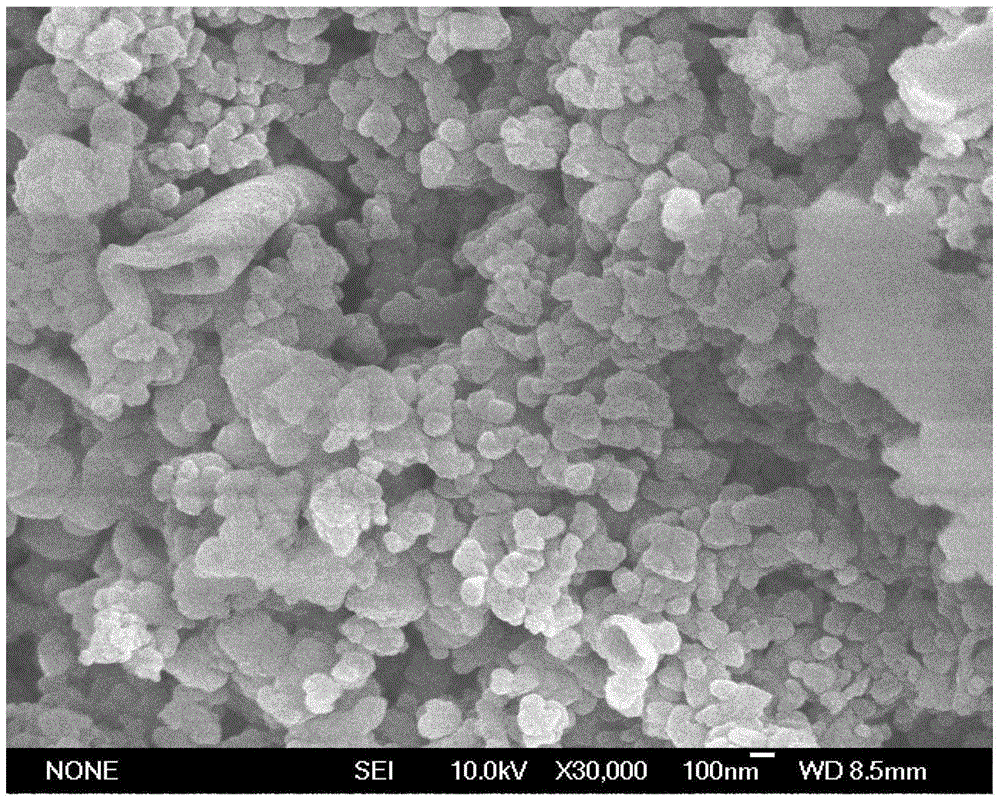

Embodiment 1

[0028] Weigh 40g of green tea and add 1L of distilled water, heat at 80°C for 1h, cool to room temperature and filter to obtain green tea extract, make a mixed solution with a total molar concentration of 0.12mol / L by making 10mmol of ferrous sulfate and 2mmol of copper chloride, and take 50mL of the mixed solution Stir at 350r / min at 45°C for 10min, and during the stirring process, add 100mL of green tea extract dropwise, continue stirring at 350r / min at 45°C for 20min after adding the green tea extract, and filter the reacted mixed solution immediately. and washed with deionized water and absolute ethanol respectively, put into a vacuum drying oven and dried at 45° C. for 12 hours, and after grinding, a green synthetic nanometer zero-valent iron-copper bimetallic material was obtained.

Embodiment 2

[0030] Weigh 50g of green tea and add 1L of distilled water, heat at 80°C for 1h, cool to room temperature and filter to obtain green tea extract, make a mixed solution with a total molar concentration of 0.12mol / L by 4.8mmol of ferrous nitrate and 1.2mmol of copper sulfate, take 20mL and mix The solution was stirred at 350r / min and 30°C for 10min, and during the stirring process, 20mL of green tea extract was added dropwise. After the dropwise addition of green tea extract was completed, the stirring was continued at 350r / min and 30°C for 20min, and the mixed solution after reaction was suction filtered immediately. , and washed with deionized water and absolute ethanol respectively, placed in a vacuum drying oven at 55° C. for 48 hours, and ground to obtain a green synthetic nanometer zero-valent iron-copper bimetallic material.

Embodiment 3

[0032] Weigh 30g of green tea and add 1L of distilled water, heat at 80°C for 1h, cool to room temperature and filter to obtain green tea extract, make 7.2mmol of ferrous chloride, 1.2mmol of copper sulfate, and 1.2mmol of copper chloride to make a total molar concentration of 0.12mol / L For the mixed solution, take 40mL of the mixed solution and stir for 10min at 350r / min at 55°C. During the stirring process, add 32mL of green tea extract dropwise. The mixed solution was suction-filtered immediately, washed with deionized water and absolute ethanol respectively, put into a vacuum drying oven at 50° C. for 20 hours, and ground to obtain a green synthetic nanometer zero-valent iron-copper bimetallic material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com