Phosphorus-containing flame retardant low-dielectric resin composition and preparation method and application thereof

一种树脂组合物、阻燃剂的技术,应用在低介电树脂组合物及其制备领域,能够解决含磷阻燃剂阻燃性能不佳、含卤阻燃剂不环保等问题,达到低介电损耗、低基板热膨胀率、低介电特性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] Embodiment 1: Preparation of structural formula (three) phosphorus-containing flame retardant

[0087] Stir and mix 206 grams of DPPO (Diphenylphosphine Oxide, diphenylphosphine oxide), 90 grams of dichloro-p-xylene and 1,200 grams of 1,2-dichlorobenzene, and heat the reaction at 160°C for 12 to 24 hours in a nitrogen atmosphere. Cool to room temperature, filter, and vacuum-dry to obtain compound A shown in structural formula (3) as a white powder, wherein the phosphorus content in compound A is about 12%.

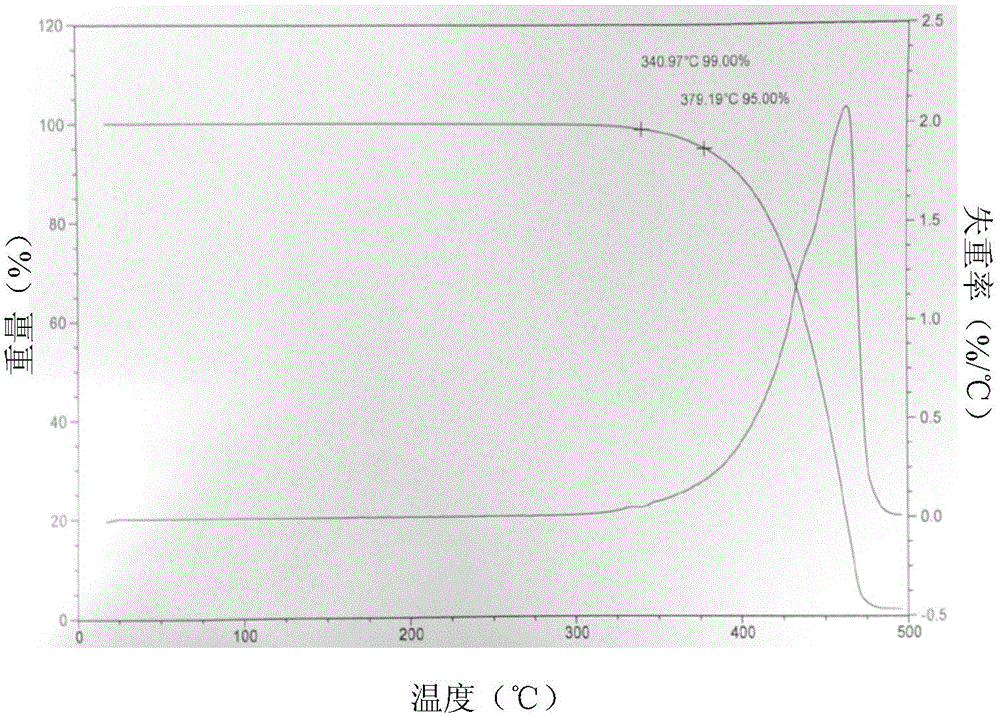

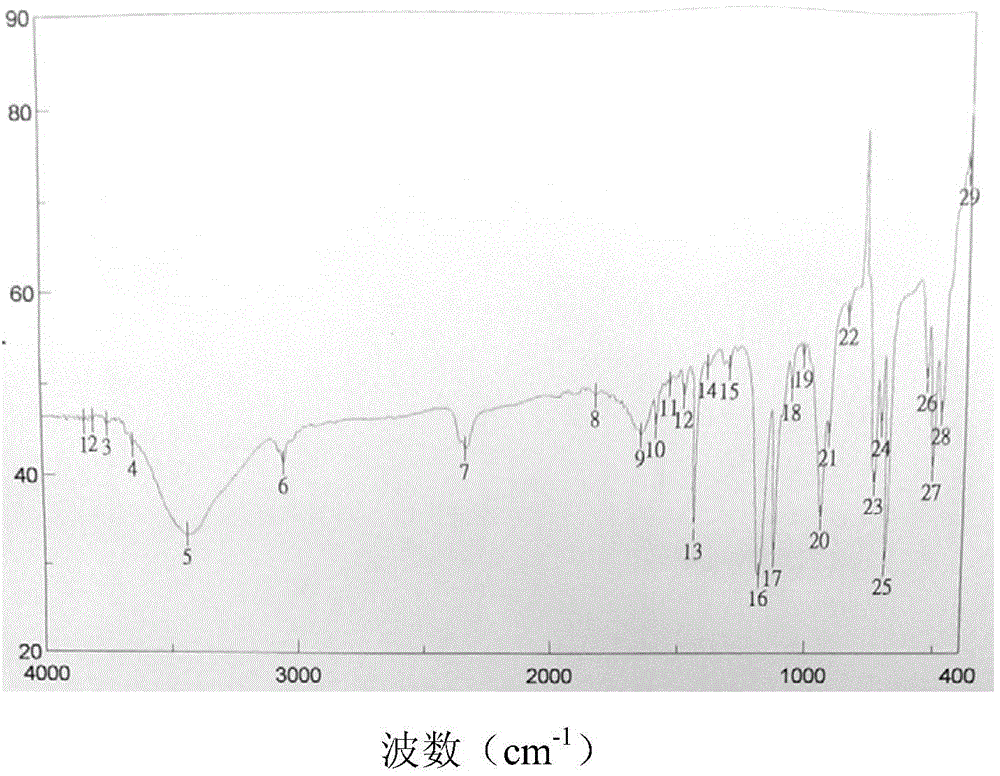

[0088] Analysis: TGA test Td value: 379 ° C (5% cracking, see the results figure 1 ); The melting point temperature measured by DSC is 334°C (results see figure 2), while the melting point of the currently used phosphazene compound (SPB-100) is 110°C, the melting point of condensed phosphoric acid ester (PX-200) is 105°C, phosphorus-containing phenolic resin, such as DOPO-bisphenol A phenolic resin, its It is a liquid resin at room temperature. It can be seen th...

Embodiment 2

[0095] Example 2: Preparation of low-dielectric resin composition containing phosphorus flame retardant

[0096] According to the formulations listed in Tables 3 to 8, the relevant components were fully mixed to obtain the resin varnish of the resin composition, wherein E represents the low-dielectric resin composition containing phosphorus flame retardant of the present invention, and C represents a comparative example.

[0097] Table 3 Formula table of low dielectric resin composition containing phosphorus flame retardant (unit: parts by weight)

[0098]

[0099] Table 4 Low-dielectric resin composition formula table containing phosphorus flame retardant (unit: parts by weight)

[0100]

[0101] Table 5 Formula table of low dielectric resin composition containing phosphorus flame retardant (unit: parts by weight)

[0102]

[0103] Table 6 Formula table of low dielectric resin composition containing phosphorus flame retardant (unit: parts by weight)

[0104]

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com