A kind of removal of cemented carbide surface al 2 o 3 and ticn composite coating method

A cemented carbide and composite coating technology, applied in chemical instruments and methods, transportation and packaging, solid waste removal, etc., can solve the problems of difficult removal of coating, easy introduction of impurities, unfavorable environment, etc., to achieve coating The effect of complete removal, uniform coating removal and uniform crack distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

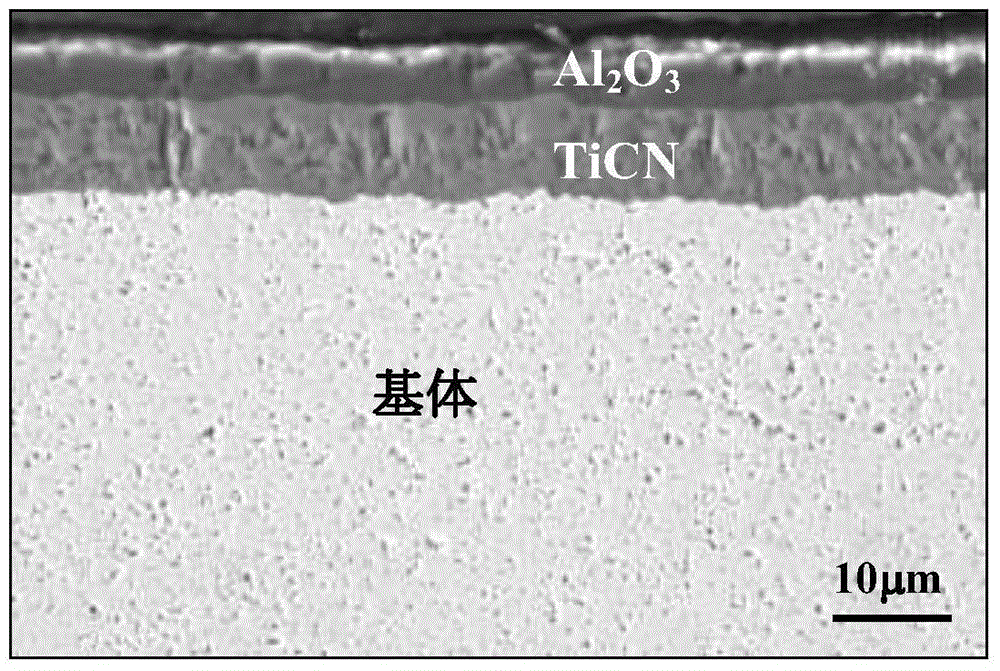

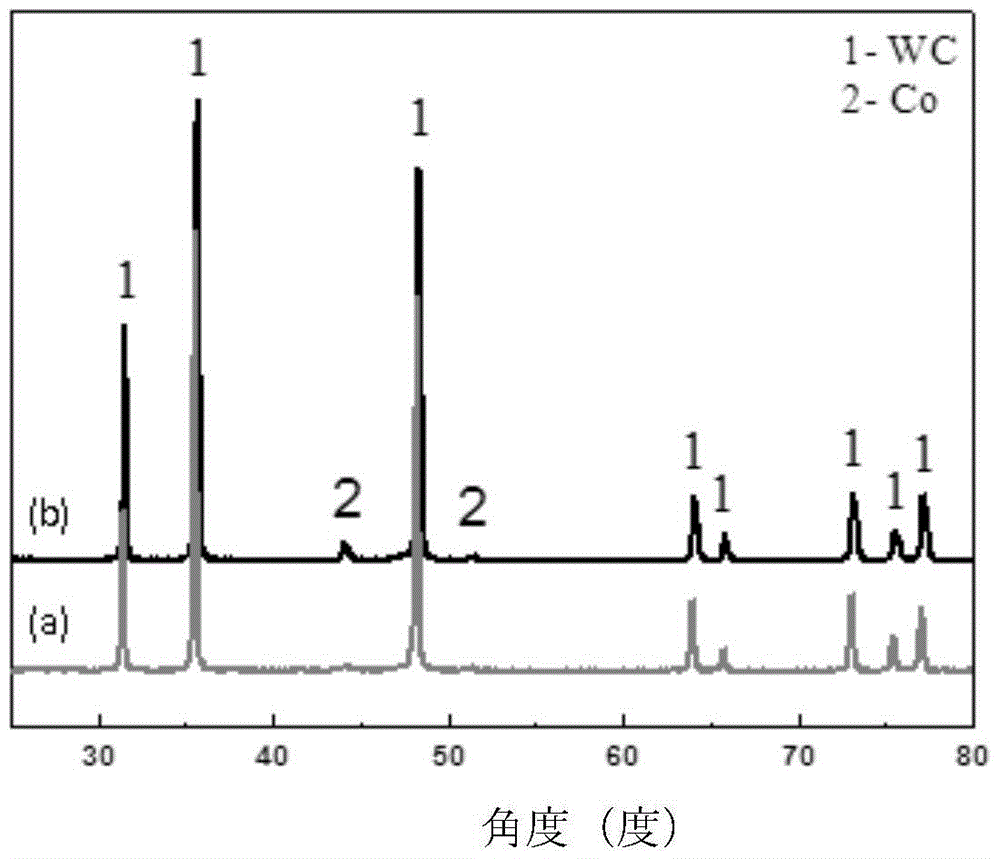

[0024] Embodiment 1: the sectional view of raw material is as figure 1 shown. The substrate is WC-10Co cemented carbide, and the coating composition in direct contact with the substrate is TiCN, with a thickness of 9 μm, Al 2 o 3 The thickness of the coating is 4μm, which is the surface layer of the sample, which is in direct contact with the outside world. The volume of the raw material sample is 730mm 3 ; Place the raw material in a muffle furnace, raise the heating rate to 950°C at a heating rate of 5°C / min, and keep it warm for 240 minutes; place the heated sample in liquid nitrogen and quench for 30s; place the quenched sample in a ball mill Wet milling is carried out in a medium, and its parameters are: the ball milling medium is water, the ball-to-material ratio is 0.5:1, the grinding ball is a hard alloy ball with a diameter of φ3mm, the ball milling speed is 120 rpm, and the ball milling time is 30 minutes; after ball milling, filter Remove impurities, dry and remo...

Embodiment 2

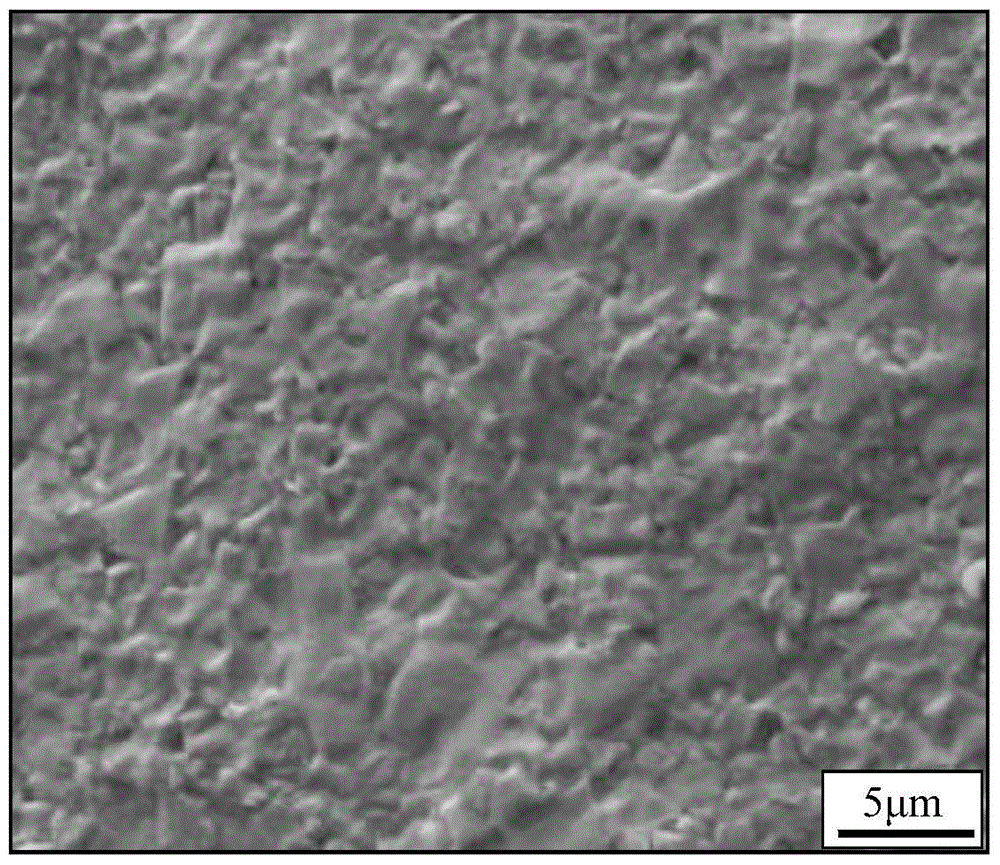

[0025] Embodiment 2: the matrix of raw material is the WC-16Co cemented carbide that contains inhibitor, and TiCN coating thickness is 12 μ m, Al 2 o 3 Coating thickness is 6μm, alloy volume is 20mm 3 . Put the raw material in a muffle furnace, raise the heating rate to 800°C at a heating rate of 8°C / min, and keep it warm for 50 minutes; place the heated sample in liquid nitrogen and quench it for 50s, and the surface morphology and composition of the sample after quenching Such as Figure 4 As shown; after quenching, the sample is placed in a ball mill for wet grinding. The parameters are: the ball milling medium is water, the ball-to-material ratio is 0.5:1, the grinding ball is a carbide ball with a diameter of φ5mm, and the ball milling speed is 100 rpm , the ball milling time is 45 minutes; after ball milling, filter out impurities, dry and remove balls; place the obtained sample in a muffle furnace at 1000°C for 40 minutes and then carry out wet milling, the ball mill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com