Preparation process of pulping prehydrolysis liquid based on advanced oxidation-nanofiltration technology

A pre-hydrolyzate and preparation technology, which is applied in pulping of cellulose raw materials, textiles, papermaking, papermaking, etc., can solve the problems of reduced yield of fermentation products, reduced fermentation efficiency, and residual organic solvents, etc., to reduce production costs and The effects of environmental pollution and simple process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

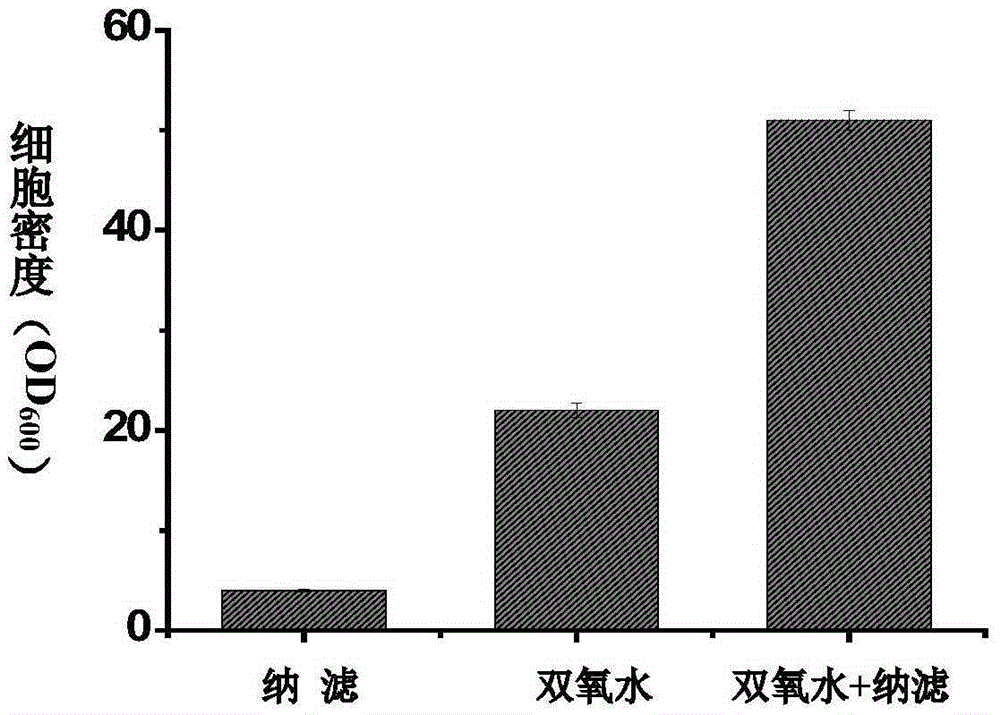

Embodiment 1

[0032] Put 1 kg of peeled poplar wood chips and 6 kg of water into the cooking pot, raise the temperature to 160°C for 20-60 minutes, keep this temperature for 2 hours, and separate the prehydrolyzed solution and pretreated wood chips after cooling down to 40°C. After the pre-hydrolyzate was concentrated by vacuum distillation at a temperature of 40°C for 5 times, the pH of the pre-hydrolyzate was adjusted to 2.5 with 1M sulfuric acid, allowed to stand for 30 minutes, filtered and the filtered pre-hydrolyzate was collected. Adjust the pH of the prehydrolyzate to 8.0 with sodium hydroxide, let stand for 30 minutes, filter and collect the filtered prehydrolyzate. Then add hydrogen peroxide to the pre-hydrolyzate to 5 g / L, pH 8.0, treat at 30° C. for 3 hours, and remove the precipitate by microfiltration. Adjust the pH to 3.5 and the dry matter content to 3%, and then inject the prehydrolyzed solution with a volume of 1000ml into the concentrated chamber of the nanofiltration dev...

Embodiment 2

[0034] Add 1 kg of peeled eucalyptus wood chips into the cooking pot, feed steam to raise the temperature to 170°C, keep this temperature for 4 hours, then add 3kg of water to wash the chips, and take out the pre-hydrolyzed solution from the bottom of the cooking pot after cooling down to 60°C. After the pre-hydrolyzed solution was concentrated by vacuum distillation at 60°C by 10 times, the pH of the pre-hydrolyzed solution was adjusted to 2.0 with 1M hydrochloric acid, allowed to stand for 30 minutes, filtered and collected. Adjust the pH of the prehydrolyzate to 8.0 with potassium hydroxide, let stand for 30 minutes, filter and collect the filtered prehydrolyzate. Then add hydrogen peroxide and ferrous sulfate to the prehydrolyzate to 3 g / L and 0.2 g / L respectively, pH 3.0, treat at 25° C. for 2 hours, and remove the precipitate by microfiltration. Adjust the pH to 3.5 and the dry matter content to 2.5%, and then inject the prehydrolyzate with a volume of 1000ml into the co...

Embodiment 3

[0036] Add 1 kg of peeled masson pine wood chips and 10 kg of water into the cooking pot, raise the temperature to 180°C for 20-60 minutes, keep this temperature for 1 hour, and separate the prehydrolyzed solution and pretreated wood chips after cooling down to 50°C. After the prehydrolyzed solution was concentrated by vacuum distillation at a temperature of 50°C by 8 times, the pH of the prehydrolyzed solution was adjusted to 2.5 with 1M nitric acid, allowed to stand for 30 minutes, filtered and collected. Adjust the pH of the prehydrolyzate to 9.0 with sodium hydroxide, let stand for 30 minutes, filter and collect the filtered prehydrolyzate. Then add hydrogen peroxide and ozone to the prehydrolyzate to 8 g / L and 0.5 g / L respectively, pH 9.0, treat at 35° C. for 7 hours, and remove the precipitate by microfiltration. Adjust the pH of the pre-hydrolyzed solution to 3.5, and the dry matter content is 3%. Then, the pre-hydrolyzed solution with a volume of 1000ml is injected int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com