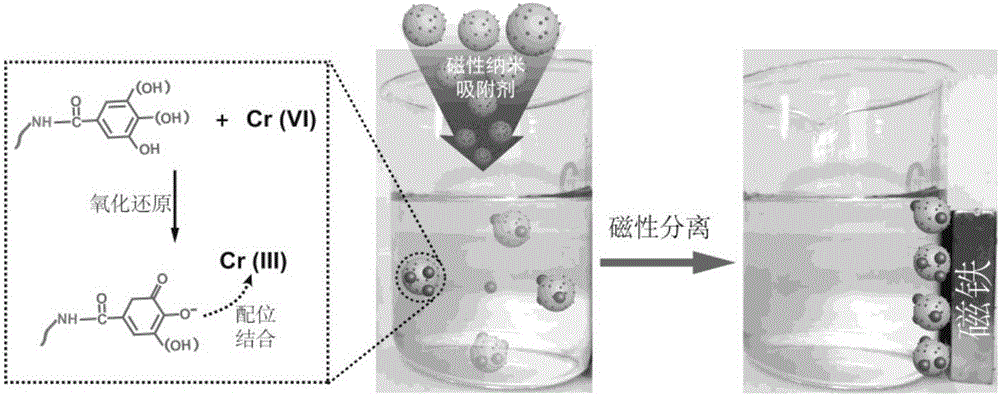

Hexavalent chromium-wastewater treatment method integrating 'reduction, adsorption and magnetic removal'

A hexavalent chromium and wastewater technology, applied in the direction of adsorption water/sewage treatment, reduced water/sewage treatment, magnetic field/electric field water/sewage treatment, etc., can solve the problems of practical application limitations, secondary pollution, and high cost of ion exchange methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

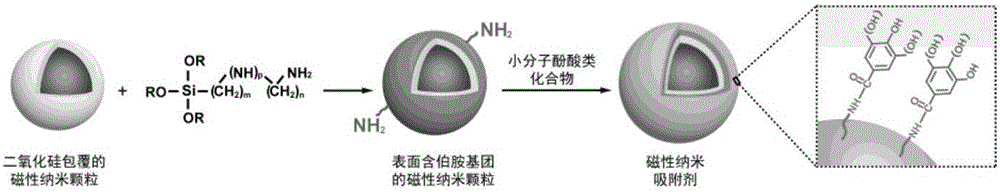

[0024] (1) Preparation of magnetic nanoparticles containing primary amine groups on the surface: 1.2 parts of Fe with a particle size of 12nm 3 O 4 And 0.8 parts with a particle size of 15nm γ -Fe 2 O 3 After being coated with silica, disperse in 100 parts of toluene, and ultrasonically shake at room temperature for 10 minutes; then add 1 part dropwise γ -Aminopropyltriethoxysilane coupling agent, while raising the temperature to 85°C and reacting for 16 hours, the product obtained is separated with a magnet and washed repeatedly with absolute ethanol, and finally dried to a constant weight;

[0025] (2) Preparation of magnetic nano-adsorbent: Disperse more than 1 part of the prepared magnetic nanoparticles containing primary amine groups on the surface in 100 parts of dichloromethane, and add 1 part of dicyclohexyl carbon dioxide under continuous stirring and nitrogen protection. Imine, 0.4 parts 4 -Dimethylaminopyridine, 0.2 parts of gentisic acid, react at -20°C for 20 hours aft...

Embodiment 2

[0029] (1) Preparation of magnetic nanoparticles with primary amine groups on the surface: 4 parts with a particle size of 30 nm γ -Fe 2 O 3 Disperse in 120 parts after being coated with silica N,N -In dimethylformamide, and ultrasonically shake at room temperature for 15 minutes; then add 2 parts dropwise γ -Aminopropyltrimethoxysilane coupling agent, while raising the temperature to 100°C and reacting for 20 hours, the product obtained is separated with a magnet and washed repeatedly with absolute ethanol, and finally dried to a constant weight;

[0030] (2) Preparation of magnetic nano-adsorbent: Disperse more than 2 parts of magnetic nanoparticles containing primary amine groups on the surface in 130 parts N,N -In dimethylformamide, add 1.5 parts of diisopropylcarbodiimide, 0.6 parts under the protection of nitrogen under continuous stirring 4 -Dimethylaminopyridine, 0.5 part of pyrogallic acid, react at 40°C for 25 hours after the addition is complete, after the reaction is c...

Embodiment 3

[0034] (1) Preparation of magnetic nanoparticles containing primary amine groups on the surface: 6 parts of Fe with a particle size of 15 nm 3 O 4 After being coated with silica, disperse in 160 parts of toluene, and ultrasonically shake at room temperature for 20 minutes; then add 3 parts dropwise N - β (Aminoethyl)- γ -Aminopropylmethyldimethoxysilane coupling agent, while raising the temperature to 110°C for 28 hours, the obtained product is separated with a magnet and washed repeatedly with absolute ethanol, and finally dried to a constant weight;

[0035] (2) Preparation of magnetic nano-adsorbent: Disperse more than 3 parts of the prepared magnetic nanoparticles with primary amine groups on the surface in 160 parts of phosphate buffer solution, and add 2 parts under continuous stirring and nitrogen protection 1 -( 3 -Dimethylaminopropyl)- 3 -Ethylcarbodiimide, 0.8 parts N -Hydroxysuccinimide, 0.8 parts of protocatechuic acid, react at 40℃ for 28 hours after the addition is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com