Magnetic core-shell type ionic liquid immobilized lipase preparation method and application to edible oil processing

A technology for immobilizing lipase and ionic liquid, applied in the direction of immobilization on or in inorganic carriers, immobilization on/in organic carriers, sustainable manufacturing/processing, etc., can solve the problem of increasing the risk of cardiovascular and cerebrovascular diseases, Use limitations and other issues to achieve the effects of good catalytic activity and specificity, increased loading, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

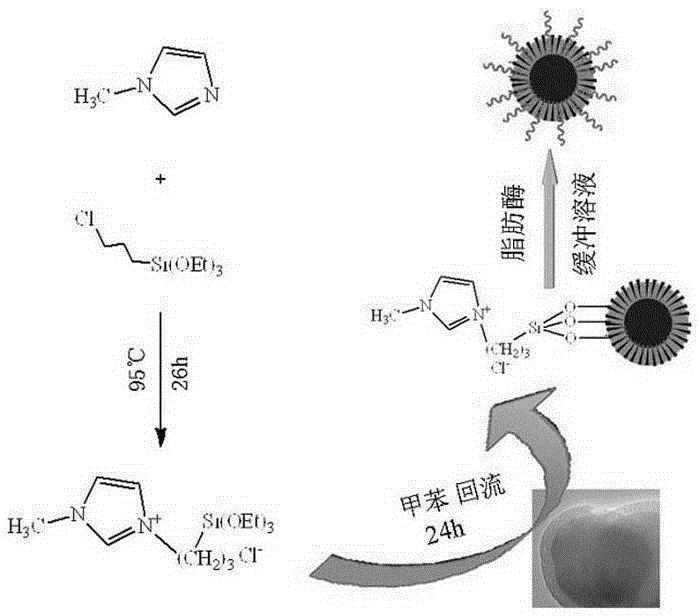

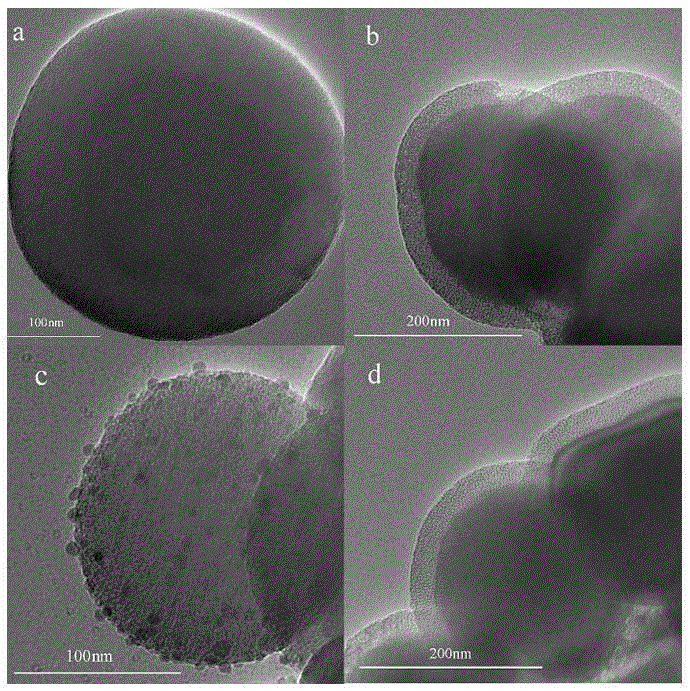

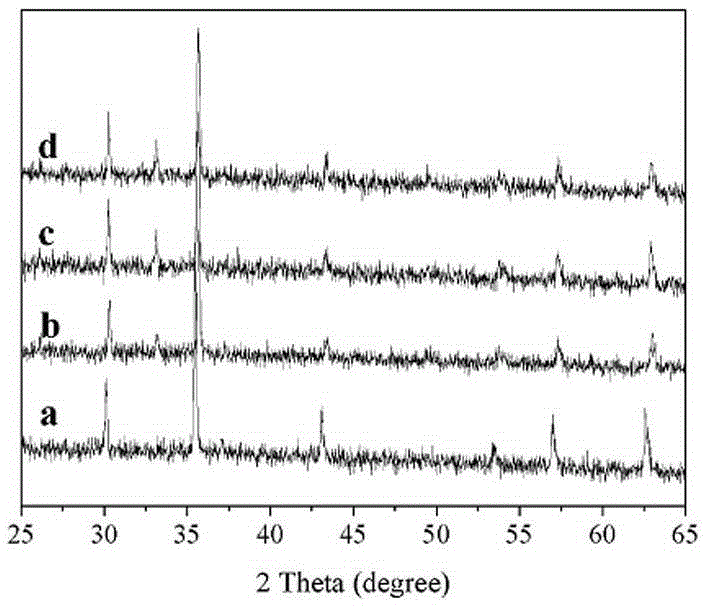

[0034] Such as figure 1 Shown, the preparation method of magnetic core-shell type ionic liquid immobilized lipase of the present invention comprises the following steps:

[0035] First step, Fe 3 o 4 Preparation of MCM-41 Core-Shell Composite

[0036] Firstly, Fe was prepared by chemical co-precipitation method 3 o 4 Nanoparticles:

[0037] FeCl 3 ·6H 2 O, FeSO 4 ·7H 2 O. Add distilled water into a three-neck round bottom flask, stir it mechanically to dissolve it completely and mix it evenly, then slowly add an appropriate amount of ammonia water to adjust the pH of the solution to 10, and a large amount of black precipitates - Fe 3 o 4 Nanoparticles, continue to stir and react for 1 h, then transfer the solution to a beaker, wash with distilled water, absolute ethanol, and trisodium citrate solution, and then wash the Fe 3 o 4 Nanoparticles are magnetically separated under the action of an external magnetic field, and vacuum-dried at 60°C, ground and stored in...

Embodiment 1

[0052] (1) Fe 3 o 4 Preparation of nanoparticles

[0053] Fe 3 o 4 Nanoparticles were prepared by chemical co-precipitation method. Weigh 8.1gFeCl 3 ·6H 2 O, 3.9g FeSO 4 ·7H 2 0 and 150ml of distilled water were added to a 250ml three-necked round-bottomed flask, mechanically stirred to make it completely dissolved and uniformly mixed, then slowly added an appropriate amount of ammonia water, and the pH of the solution was adjusted to be 10, and a large amount of Fe was quickly generated in the mixed solution. 3 o 4 Nanoparticles (black precipitate), continue to stir and react for 1h, transfer the solution to a 250ml beaker, wash with distilled water, absolute ethanol, and 0.3mol / L trisodium citrate solution for 3 times, and then wash the Fe 3 o 4 Nanoparticles are magnetically separated under the action of an external magnetic field, and vacuum-dried at 60°C, ground and stored in a centrifuge tube for later use;

[0054] (2) Fe 3 o 4 Preparation of MCM-41 composi...

Embodiment 2

[0065] Fe 3 o 4Nanoparticles and Fe 3 o 4 The preparation of the MCM-41 composite material is the same as in Example 1.

[0066] Functional modification of the support: 20 mmol of methylimidazole and 20 mmol of trichloropropyltriethoxysilane were added into a 250 mL three-necked flask, and stirred and reacted at 95° C. for 26 h under nitrogen protection. Then, 1.0gFe 3 o 4 The MCM-41 composite material was added to the above system, and 100 mL of ethanol was added as a solvent, protected by nitrogen, and refluxed at 90° C. for 24 hours. After the reaction, the product was magnetically separated, washed several times with absolute ethanol and ether, and vacuum-dried at 40°C to obtain the ionic liquid-modified carrier IL-Fe 3 o 4 MCM-41;

[0067] Immobilization of lipase: Disperse 2.0 g of free lipase in 30 mL of phosphate buffer solution (0.2 mol / L, pH=7.0), and then add 1.0 g of the above-mentioned ionic liquid modified magnetic composite carrier IL-Fe 3 o 4 MCM-41, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com