Combined technology method suitable for efficient processing of calcium fluoride convex cone mirror

A combined process and calcium fluoride technology, applied in the direction of stone processing tools, stone processing equipment, metal processing equipment, etc., can solve the problems of roughness and smoothness control difficulties, no experience in axicon mirror processing, inconsistent mirror curvature changes, etc. Achieve the effect of controllable surface shape accuracy and roughness, great breakthrough and stability, and strong shear yield stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

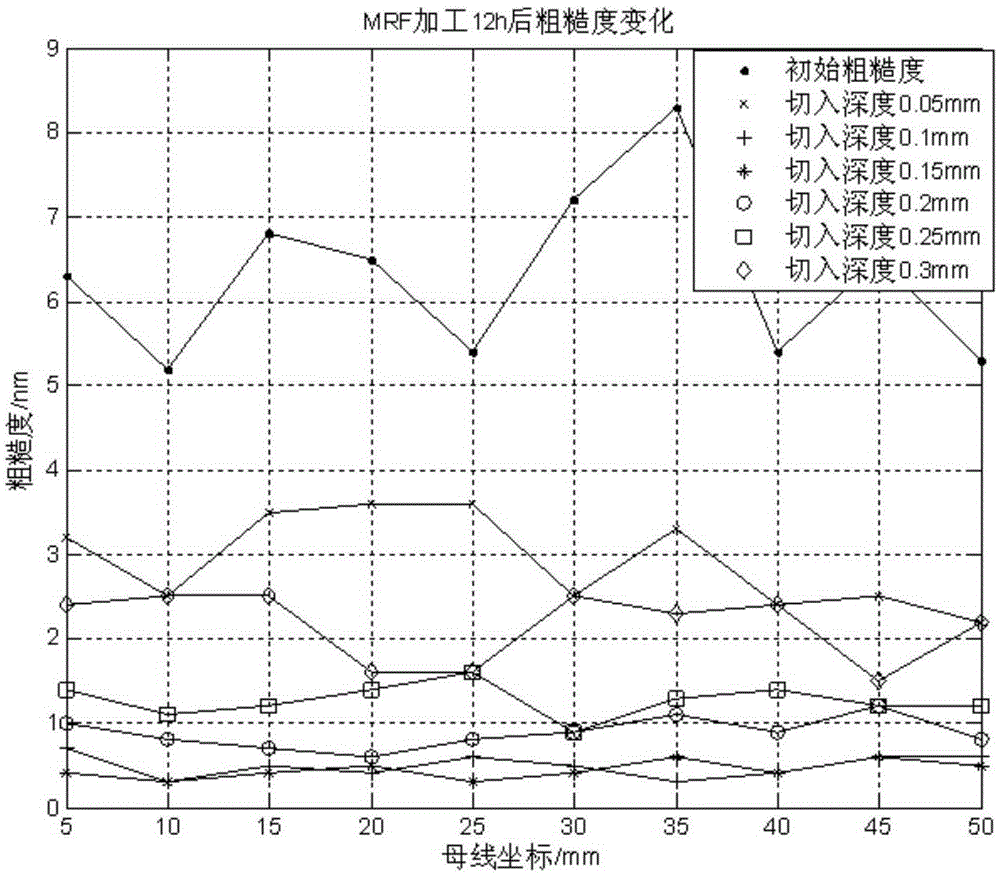

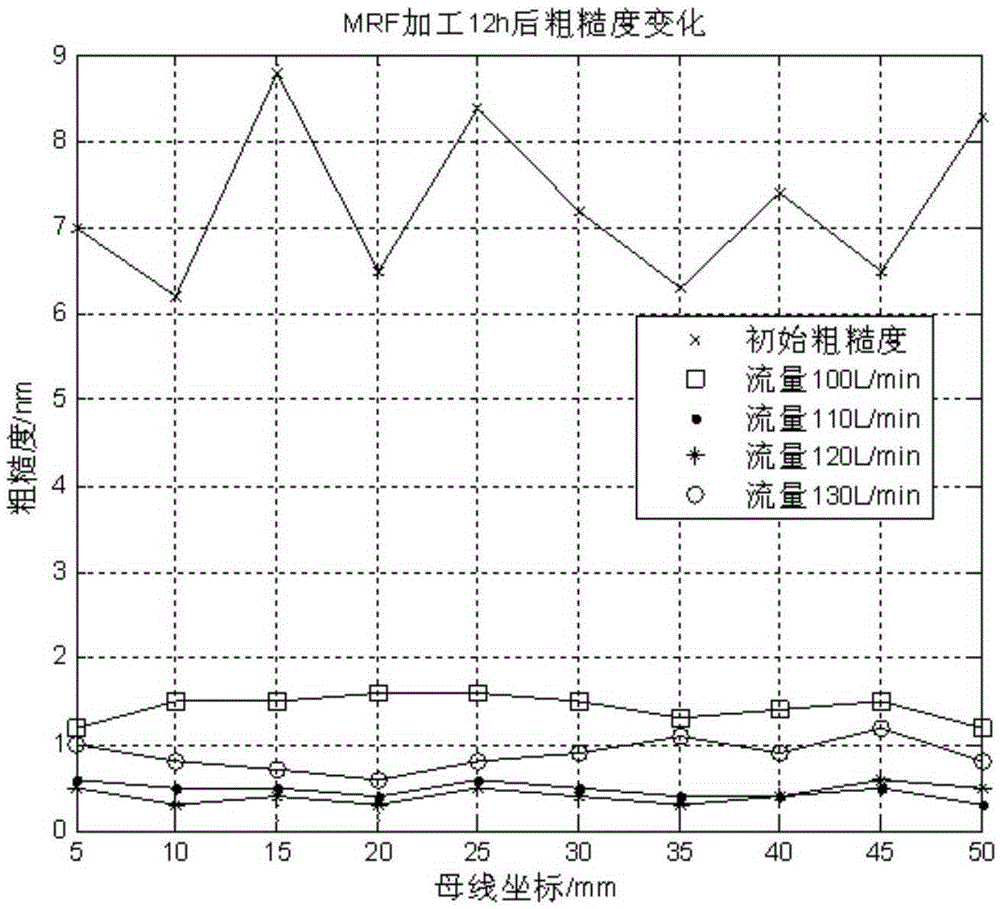

[0036] The present invention is a combined process method suitable for high-efficiency processing of calcium fluoride convex cone mirrors. According to the three processing processes of calcium fluoride convex cone forming, surface shape precision improvement and roughness improvement, milling and grinding forming technology and diamond turning are respectively adopted. Technology and magnetorheological polishing technology for combined processing;

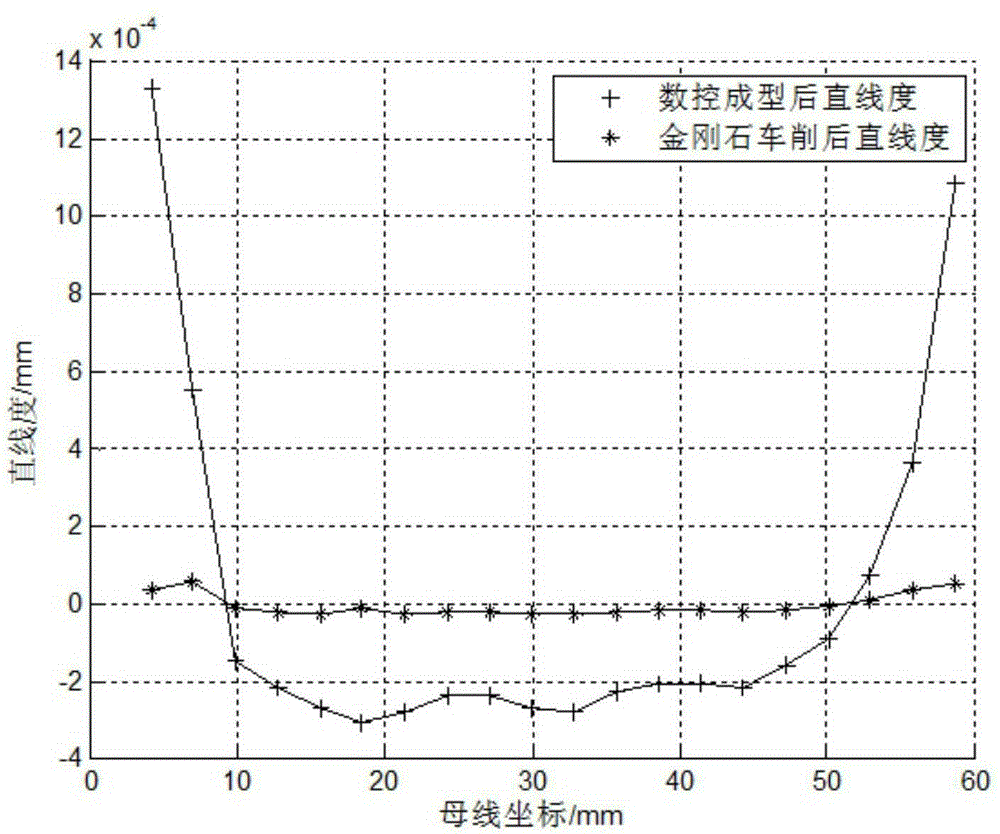

[0037] The milling and grinding forming technology is to quickly mill and grind the calcium fluoride convex spherical surface closest to the radius of the ball into a calcium fluoride convex cone mirror by using a CNC milling machine. By coaxially installing the calcium fluoride convex spherical surface on the turntable and rotating the turntable until the generatrix of the conical mirror is at a hor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area mean particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com