A kind of microvascular liver chip based on cell aggregates and methods of making and using the same

A technology of microvessels and aggregates, applied in biochemical equipment and methods, methods of supporting/immobilizing microorganisms, tissue cell/virus culture devices, etc., can solve problems such as single structure and few simulated functions, and achieve high Density, to achieve mutual promotion, to achieve the effect of information exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The method for preparing the microvascular liver chip based on cell aggregates includes the following steps:

[0045] (1) Use computer-aided design software (such as Auto-CAD or Solidwork) to design and draw the mask of the organ chip, and accurately draw the microstructure and microchannel graphics of each layer of the chip;

[0046] (2) Through micro-processing technology, especially the method of photolithography, two upper and lower masks are prepared, and chips containing microstructures and microchannels are prepared;

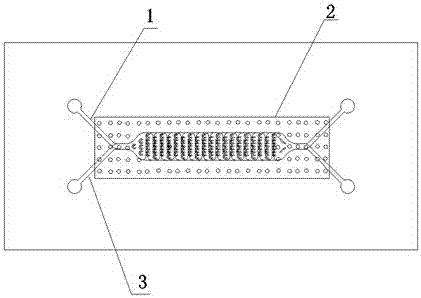

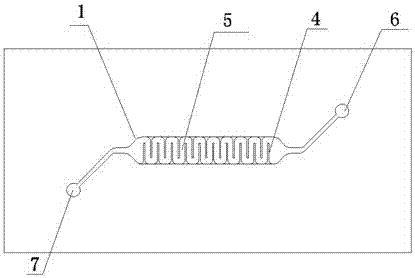

[0047] (3) Align, pressurize, and perform plasma bonding on the upper microvasculature chip, the middle porous membrane and the lower liver organ multicellular co-culture system to form a three-dimensional microstructure and microchannel network;

[0048] (4) Plant different cell types sequentially through the entrance of microvessels and the entrance channel of the culture system, and perform adherent and three-dimensional aggregate culture, and c...

Embodiment 1

[0054] Example 1 Design and Fabrication of Microvascular Liver Chip Based on Cell Aggregates

[0055] Use computer-aided design software (such as Auto-CAD or Solidwork, etc.) to design and draw the microstructure and microchannel graphics of the microvascular liver chip based on cell aggregates. Firstly, the photoresist is spin-coated on the negative, and the photoresist mold is formed after photolithography and self-development. The silicon mold is made by the silicon deep etching technology in micro-electromechanical processing, and the microstructure of the chip can also be processed by the numerical control CNC system. and microchannels. Mix the prepolymer of polydimethylsiloxane (PDMS) with the curing agent, and cast it on the mold of the upper and lower two layers of chips after ultrasonic, stirring, vacuum degassing and other steps, and heat reaction at 70~80℃ for 1~ Heat reaction at 65°C for 3 hours or overnight, then cool naturally. The polydimethylsiloxane (PDMS) c...

Embodiment 2

[0056] Example 2 Cell implantation and localized culture of the liver chip multi-cell co-culture system

[0057] Close the inlet and inlet of the liver multi-cell co-culture system channel, open the inlet and outlet of the microvasculature, through the inlet of the microvasculature, slowly flow the endothelial cell culture solution through the microchannel into the curved vessels of the microvasculature Inside, delicately culture for 2-4 hours, until the endothelial cells adhere to the wall and grow on the porous membrane in the middle to form a vascular endothelial barrier. Close the inlet and outlet of the microvasculature, open the outlet and inlet of the liver multi-cell co-culture system, and slowly inject the culture medium of liver cell aggregates prepared by the hanging drop method into the cavity of the liver multi-cell co-culture system. Relatively small, the culture medium and single cells are easy to pass through, while the diameter of the cell aggregate is relativ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com