Intelligent multi-axis flight device for line routine inspection

An intelligent and aircraft technology, applied in aircraft, transportation and packaging, overhead line/cable equipment, etc., can solve the problems of increasing the workload of staff, extra labor costs, and a large amount of manpower and material resources, so as to reduce the intensity of manual labor and reduce work Dangerous, low-cost production effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

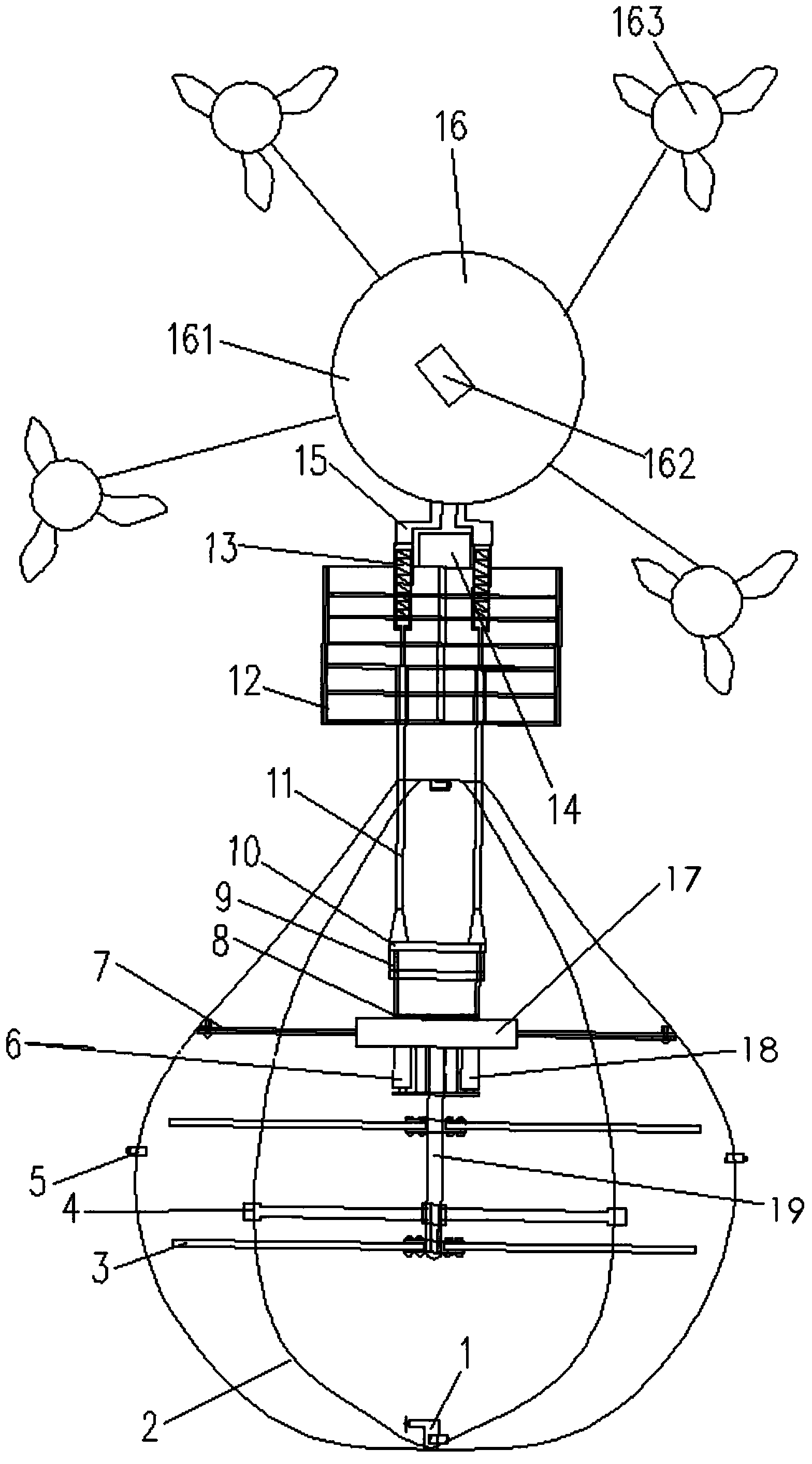

[0024] See attached figure 1 , the intelligent multi-axis flight line inspection device of the present invention includes a main high-definition camera 1, an anti-collision net 2, a main propeller 3, an auxiliary propeller 4, a drive motor, a fixed bracket 7, a bearing 8, a circuit board 9, and a lithium battery 10. Connecting rod 11, hanging basket 12, data processing transmitter 14, aircraft connecting shaft 15 and aircraft 16;

[0025] Described aircraft 16 comprises a fixed spherical shaft 161, four flying wings 163 installed on the fixed spherical shaft 161 and the gyroscope 162 installed on the fixed spherical shaft 161; on the outer circumference of the ball shaft 161;

[0026] The below of the fixed ball shaft 161 is fixedly provided with the aircraft connecting shaft 15, and the hanging basket 12 is fixed on the lower end of the aircraft connecting shaft 15; the hanging basket 12 is installed on the top of the connecting rod 11, and the connecting rod 11 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com