Method for preparing solid light-emitting carbon point

A technology of solid-state luminescence and carbon dots, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of unfavorable dispersion, long synthesis cycle, easy film formation, etc., and achieve the effects of good water solubility, easy dispersion, and simple synthesis path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

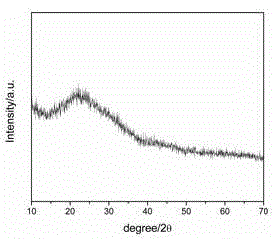

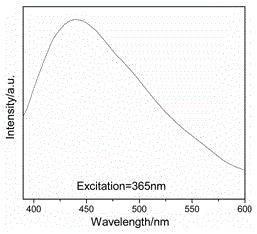

[0028] A method for preparing solid-state luminescent carbon dots, comprising the steps of:

[0029] a. Weigh 1.5g of sorghum noodles and disperse them in 60ml of deionized water to prepare a precursor solution with a concentration of 0.025g / ml, and stir fully on a magnetic stirrer for 30min.

[0030] b. Put the stirred precursor solution into an autoclave, and heat it at 180°C for 4 hours.

[0031] c. Centrifuge the reacted product at a centrifugal rate of 6000rpm for 10 minutes to remove large particles of impurities and collect the filtrate; then filter the filtrate from the previous step with a filter membrane with a pore size of 0.22 μm.

[0032] d. Collect the filtrate, and freeze-dry the filtrate at -50°C.

[0033] see figure 1 , is the physical photo of the solid carbon dots synthesized under this condition before and after irradiation with a 365nm ultraviolet lamp. It can be seen from the figure that under the irradiation of ultraviolet light, the carbon dots emit ...

Embodiment 2

[0039] A method for preparing solid-state luminescent carbon dots, comprising the steps of:

[0040] a. Weigh 2.0g of rice noodles and disperse them in 50ml of deionized water to prepare a precursor solution with a concentration of 0.04g / ml, and stir fully on a magnetic stirrer for 30min.

[0041] b. Transfer the stirred precursor solution into a high-pressure reactor, and heat it with water at 180°C for 3 hours.

[0042] c. Centrifuge the reacted product for 10 minutes at a centrifugal rate of 6000 rpm to remove large particles of impurities, and then filter with a filter membrane with a pore size of 0.22 μm;

[0043] d. Collect the filtrate, and freeze-dry the filtrate at -50°C.

[0044] see Figure 5 (b), is the TEM image of carbon dots prepared under this condition.

Embodiment 3

[0046] A method for preparing solid-state luminescent carbon dots, comprising the steps of:

[0047] a. Weigh 2.0g of cornmeal and disperse it in 40ml of deionized water to prepare a precursor solution with a concentration of 0.05g / ml, and fully stir it on a magnetic stirrer for 30min.

[0048] b. Transfer the stirred precursor solution into an autoclave, and heat it in water at 180°C for 4 hours.

[0049] c. Centrifuge the reacted product at a centrifugal rate of 6000rpm for 10min to remove large particles of impurities, and then filter with a filter membrane with a pore size of 0.22μm.

[0050] d. Collect the filtrate, and freeze-dry the filtrate at -50°C.

[0051] see Figure 5 (c), is the transmission electron microscope image of carbon dots prepared under this condition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com