Water-soluble low-crosslinking polymaleic anhydride-diisobutylene copolymer salt dispersant and preparation method thereof

A technology of polymaleic anhydride and diisobutylene, which is applied in the direction of coating, etc., can solve the problems of impurity problems that cannot be solved, the cost of copolymers increases, and it is difficult to remove them completely, so as to achieve good application prospects, improve production efficiency, and increase heat resistance temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

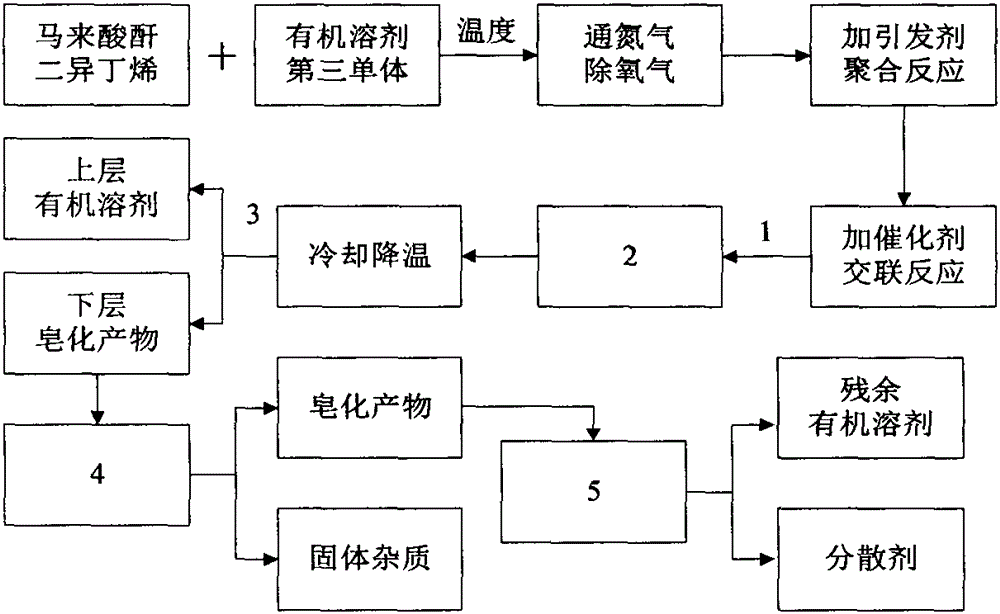

Method used

Image

Examples

Embodiment 1

[0025] (1) Synthesis of copolymer: 33.6g of diisobutylene, 29.4g of maleic anhydride, 1.52g of N-methylolacrylamide, 32g of solvent benzene and 0.15g of BPO were added to the product equipped with a thermometer, electric stirrer and condenser. Three-necked flask. Nitrogen gas was introduced for 2 minutes from a port where the thermometer was inserted as a protective gas. Heat with a water bath to control the polymerization temperature at 80°C, and polymerize for 8 hours. After the polymerization is completed, 0.09 g of ethylenediamine is added to the system for cross-linking reaction.

[0026] (2) Saponification of copolymer: Add 24 g of sodium hydroxide and 70 g of deionized water into the polymerization system. Airtightly stir and heat for 1.5 hours in a water bath at a constant temperature of 95°C.

[0027] (3) Separation of the copolymer: After the resulting mixed system is finally allowed to stand for 2.5 hours, the lower layer solution is obtained through oil-water separat...

Embodiment 2

[0029] (1) Synthesis of copolymer: 33.6g of diisobutylene, 29.4g of maleic anhydride, 5.3g of pentaerythritol triacrylate, 30g of solvent ethyl acetate and 0.2g of BPO were added to a thermometer, electric stirrer and condenser. Three-necked flask. Nitrogen gas was introduced for 2 minutes from a port where the thermometer was inserted as a protective gas. Heat with a water bath to control the polymerization temperature at 90°C, and polymerize for 4 hours. After the polymerization is completed, 0.09g methylamine and 0.18g diethylamine are added to the system for crosslinking reaction.

[0030] (2) Saponification of copolymer: Add 75g of concentrated ammonia water (mass concentration 28%) into the polymerization system. Airtightly stir and heat in a water bath at a constant temperature of 95°C for 1 hour.

[0031] (3) Separation of the copolymer: After the resulting mixed system is finally allowed to stand for 2 hours, the lower layer solution is obtained through oil-water separa...

Embodiment 3

[0033] (1) Synthesis of copolymer: 33.6g diisobutylene, 29.4g maleic anhydride, 2.7g glycidyl methacrylate, 18g benzene and 18g xylene mixed solvent, 0.18g hydrogen peroxide are added to the mixture Thermometer, electric stirrer and condenser in a three-necked flask. Nitrogen gas was introduced for 2 minutes from a port where the thermometer was inserted as a protective gas. Heat with a water bath to control the polymerization temperature at 80°C, and polymerize for 6 hours. After the polymerization is completed, 0.08 g of ethylamine and 0.08 g of triethylamine are added to the system for cross-linking reaction.

[0034] (2) Saponification of copolymer: Add 24 g of sodium hydroxide and 65 g of deionized water into the polymerization system. Airtightly stir and heat in a water bath at a constant temperature of 99°C for 1 hour.

[0035] (3) Separation of the copolymer: After the resulting mixed system is finally allowed to stand for 2 hours, the lower layer solution is obtained th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com