Titanium-iron-carbon alloy with low cost and high strength

A high-strength, carbon alloy technology, applied in the fields of material science and non-ferrous metals and their alloys, can solve the problems of increasing the manufacturing cost of titanium alloys, difficult smelting, unfavorable large-scale application of titanium alloys, etc., and achieves the effect of low cost and easy smelting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

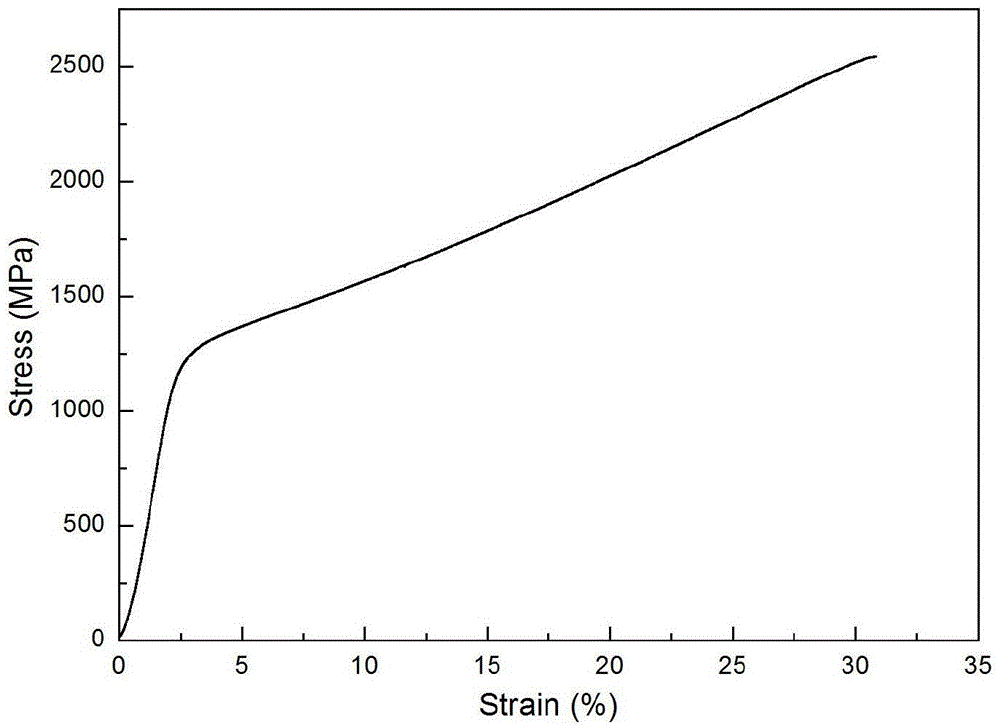

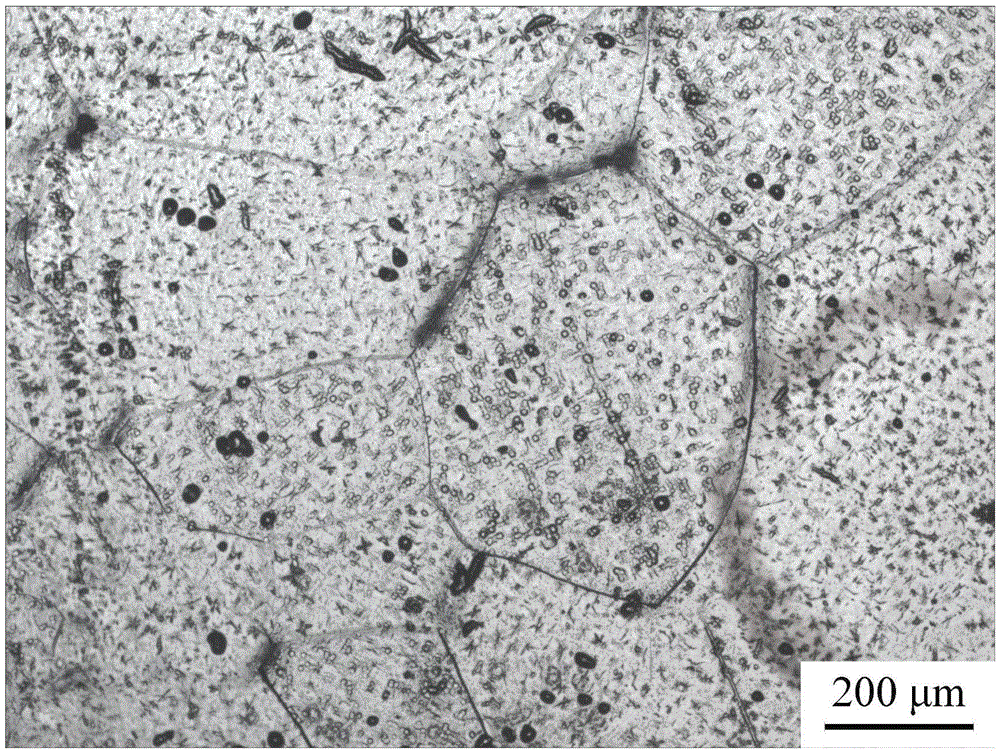

[0017] 88.5 grams of pure titanium wire and 11.5 grams of iron-carbon alloy with a carbon content of 0.45% are used for smelting in a non-consumable vacuum electric arc furnace. The background vacuum of the electric arc furnace during smelting is higher than 2.0×10 -2 Pa, the working current of the arc welding power supply is 400A, and the working voltage is 20V. After the alloy is smelted into a whole for the first time, it is turned over in the crucible for the second smelting, and this is repeated for a total of 8 times. After the alloy is smelted, an alloy sample with a size of φ5×10mm is cut from the alloy ingot by wire electric discharge cutting, and the mechanical properties are tested by a compression mechanical testing machine with an extensometer. The structure is shown in Table 1. The microstructure of the alloy was observed by optical microscope and scanning electron microscope. From figure 1 The compressive mechanical performance test of the as-cast alloy shows...

example 2

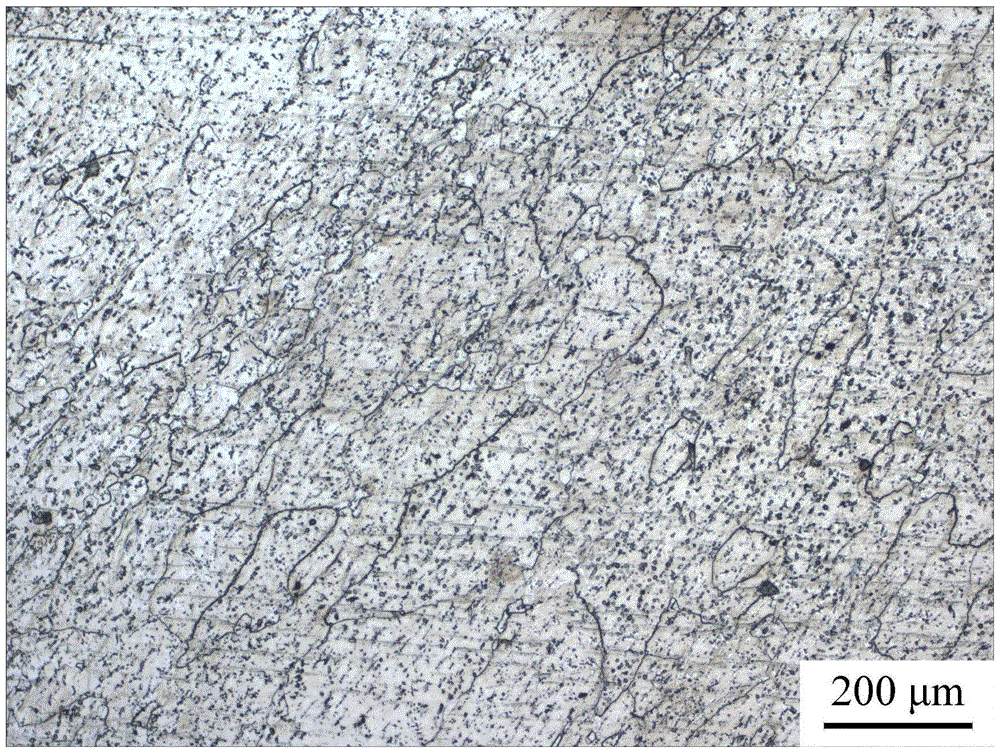

[0019] 88.5 grams of pure titanium wire and 11.5 grams of iron-carbon alloy with a carbon content of 0.56% are used for smelting in a non-consumable vacuum electric arc furnace. The background vacuum of the electric arc furnace during smelting is higher than 2.0×10 -2 Pa, the working current of the arc welding power supply is 420A, and the working voltage is 30V. After the alloy is smelted into a whole for the first time, it is turned over in the crucible for the second smelting, and this is repeated for a total of 8 times.

[0020] After the alloy has been repeatedly smelted evenly, alloy samples with length, width and height of 40, 40, and 15 are cut from the alloy ingot by wire electric discharge cutting, and rolled at 900 °C for multiple passes, and the deformation of each pass is controlled at Within 10%, the total deformation is more than 60%. After rolling, the alloy is cooled to room temperature by water quenching or air cooling. The alloy plate was cut into tensile ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Compression breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com