Artificial shoulder joint prosthesis made from organic polymer materials

An organic polymer, shoulder joint technology, used in shoulder joints, prostheses, joint implants, etc., can solve the problems of natural bone stress shielding, metal material corrosion, hindering clinical application, etc., to reduce stress shielding, reduce metal Corrosion, improve the effect of clinical use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

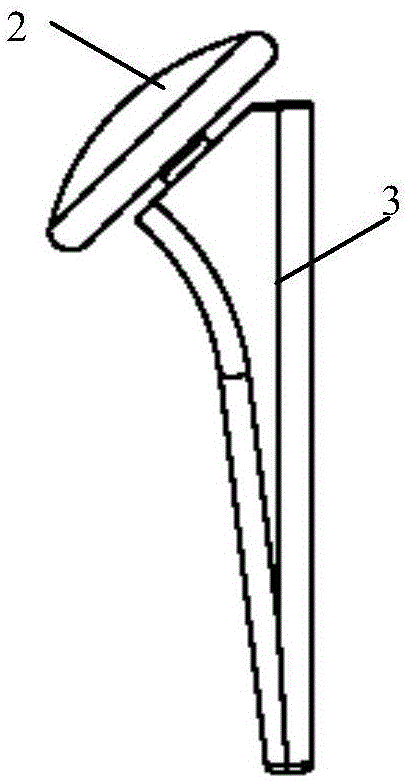

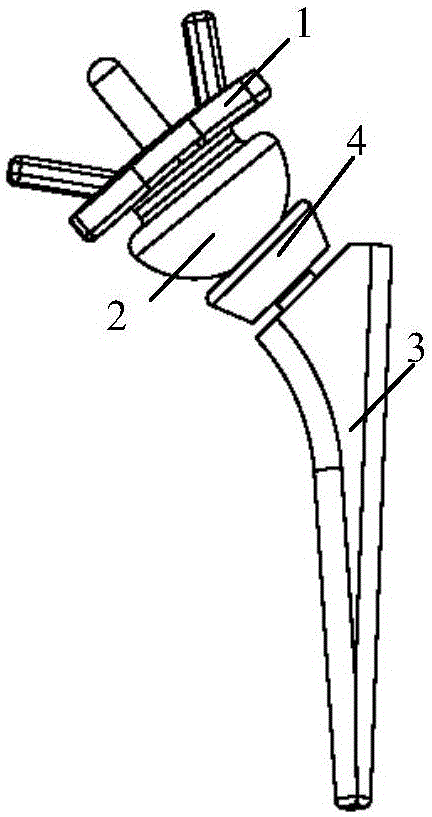

[0030] Such as figure 1 As shown, a kind of artificial shoulder joint prosthesis of organic polymer material provided by the present invention is a semi-shoulder joint prosthesis, which comprises a ball head 2 and a humerus stem 3, wherein the inner surface of the ball head 2 is concave, and the inner surface of the ball head 2 is concave. The inner surface is connected with the humerus stem 3. The ball head 2 is placed into the socket of the human body during use. The outer surface of the ball head 2 directly matches the articular cartilage of the human body. The ball head 2 is made of polyetheret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com