Plane millstone filling system with self-sharpening function

A surface grinding disc and filling system technology is applied in the field of grinding parts preparation, which can solve the problems of poor edge performance of grinding discs, low grinding efficiency, affecting the processing quality of workpieces, etc., so as to avoid overall performance degradation and improve self-sharpening. , The effect of good compatibility between organic and inorganic phases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

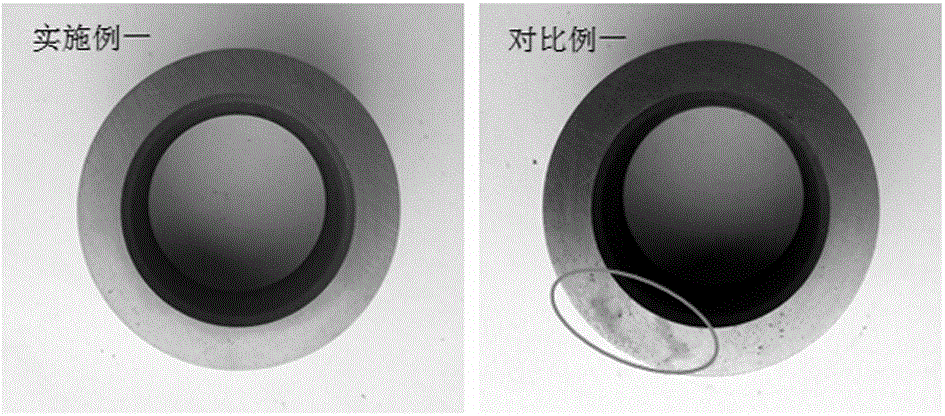

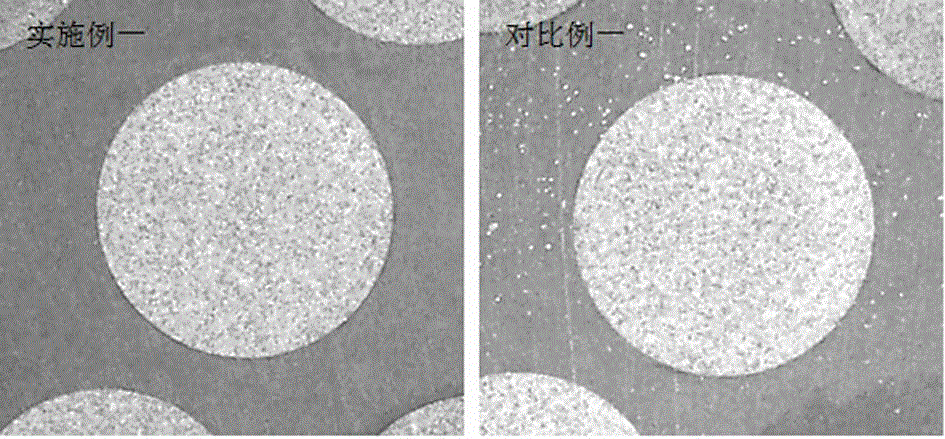

Embodiment 1

[0046] A self-sharpening flat grinding disc filling system, composed of the following raw materials in volume percentage:

[0047] Epoxy resin E5454%

[0048] Ethylenediamine 5%

[0049] Microcrystalline corundum 30%

[0052] The particle size of the above-mentioned microcrystalline corundum is 30-40 μm; the shape is non-equal-area shape, and the aspect ratio is 1.5-2.0; the particle size of dichromium trioxide is 70-90 μm.

[0053] The above filling system is used for filling the flat grinding disc, the steps are as follows:

[0054] The first step is to mix the materials. Put the epoxy resin, microcrystalline corundum, chromium trioxide, and absolute ethanol in the glass container in sequence according to the above volume percentages. After pre-mixing evenly, slowly add the curing agent ethylenediamine, adding Stir until well mixed;

[0055] The second step, casting, pour the mixed flat grinding disc filling s...

Embodiment 2

[0059] A self-sharpening flat grinding disc filling system, composed of the following raw materials in volume percentage:

[0060] Epoxy resin E5150%

[0061] Ethylenediamine 6%

[0062] Microcrystalline corundum 28%

[0063] Chromium trioxide 4%

[0065] The particle size of the microcrystalline corundum is 30-40 μm; the shape is non-equal area, and the aspect ratio is 1.5-2.0; the particle size of the dichromium trioxide is 70-90 μm.

[0066] According to the method of Example 1, the above-mentioned filling system was used to cure at room temperature for 24 hours to prepare a Ф1020 ceramic diamond flat grinding disc, and the properties of the processed cemented carbide cutter grains are shown in Table 1.

Embodiment 3

[0068] A self-sharpening flat grinding disc filling system, composed of the following raw materials in volume percentage:

[0069] Epoxy resin E4440%

[0070] Ethylenediamine 4%

[0071] Microcrystalline corundum 40%

[0072] Chromium trioxide 10%

[0073] Absolute ethanol 6%

[0074] The particle size of the microcrystalline corundum is 20-80 μm; the shape is non-equal-area shape, the aspect ratio is 1.5-2.0, and the particle size of the chromium trioxide is 70-90 μm.

[0075] According to the method of Example 1, the above-mentioned filling system was used to cure at room temperature for 12 hours to prepare a Ф840 ceramic diamond flat grinding disc, and the properties of the processed cemented carbide cutter grains are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com