Epoxy grouting material for glass fiber sleeve reinforcing system and preparing method of epoxy grouting material

A technology of epoxy grouting and glass fiber sleeves, which is applied in the field of grouting materials for structural repair and reinforcement. It can solve the problems of affecting strength, lack of compactness, and poor self-leveling of grouting materials, and achieves good chemical resistance, long service life, and applicability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

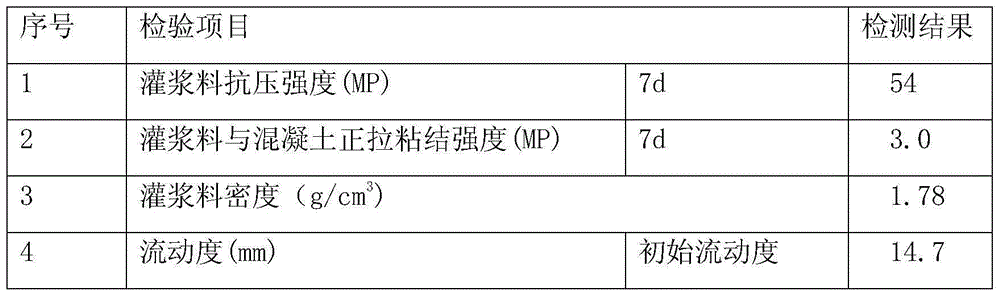

Examples

Embodiment 1

[0053] The epoxy grouting material used in the glass fiber sleeve reinforcement system provided in this embodiment is composed of A component, B component, and C component mixed in a mass ratio of 2:1:3, in which:

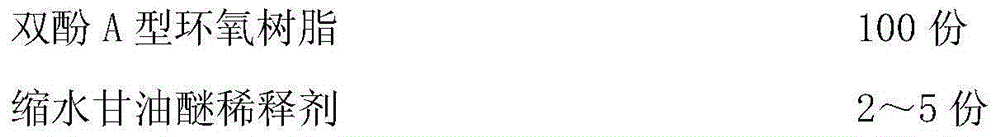

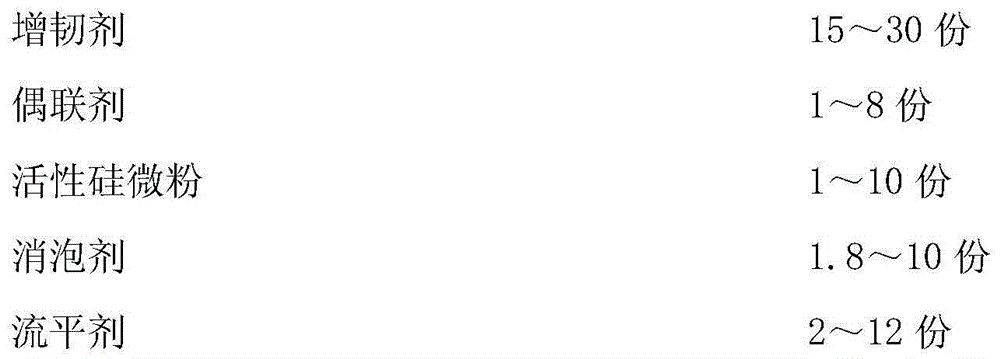

[0054] The A component is mainly composed of the following raw materials in parts by weight:

[0055] Bisphenol A epoxy resin 100kg

[0056] N-Butyl glycidyl ether 2kg

[0057] Liquid polysulfide rubber 20kg

[0058] KH-5502kg

[0059] Active silica powder 800 mesh 5kg

[0060] Mixture of foam-breaking polymer and organosilicon fluoroalkane 2kg

[0061] Alkyl aryl modified silicone 3kg

[0062] The B component is mainly composed of the following raw materials in parts by weight:

[0063] Phenalkamine curing agent 100kg

[0064] The C component is mainly composed of the following raw materials in parts by weight:

[0065] 20~30 mesh quartz sand 18kg

[0066] 30~40 mesh quartz sand 36kg

[0067] 40~70 mesh quartz sand 45kg

[0068] Fly ash 45kg

[0069] Barite powder 25kg

[0070] Prepara...

Embodiment 2

[0084] The epoxy grouting material used in the glass fiber sleeve reinforcement system provided in this embodiment is mainly composed of the A component, the B component, and the C component in a 2:1:2 mass ratio. Among them:

[0085] The A component is mainly composed of the following raw materials in parts by weight:

[0086] Bisphenol A epoxy resin 100kg

[0087] Allyl glycidyl ether 3kg

[0088] Liquid nitrile rubber 15kg

[0089] KH-5601kg

[0090] Active silica powder 600 mesh 1kg

[0091] Modified silicone and silica mixture 10kg

[0092] Polymethyl alkyl and polyethylene glycol ether copolymer solution 12kg

[0093] The B component is mainly composed of the following raw materials in parts by weight:

[0094] Phenalkamine curing agent 110kg

[0095] The C component is mainly composed of the following raw materials in parts by weight:

[0096] 20~30 mesh quartz sand 30kg

[0097] 30~40 mesh quartz sand 45kg

[0098] 40~70 mesh quartz sand 30kg

[0099] Fly ash 60kg

[0100] Barite powder 35...

Embodiment 3

[0115] The epoxy grouting material used in the glass fiber sleeve reinforcement system provided in this embodiment is composed of A component, B component, and C component mixed in a mass ratio of 2:1:10, in which:

[0116] The A component is mainly composed of the following raw materials in parts by weight:

[0117] Bisphenol A epoxy resin 100kg

[0118] Difunctional polypropylene glycol diglycidyl ether 5kg

[0119] Sea-island structure toughening agent BE30kg

[0120] KH-5708kg

[0121] Active silica powder 3000 mesh 10kg

[0122] Organically modified polysiloxane 1.8kg

[0123] Polyether modified polydimethylsiloxane 2kg

[0124] The B component is mainly composed of the following raw materials in parts by weight:

[0125] Phenalkamine curing agent 80kg

[0126] The C component is mainly composed of the following raw materials in parts by weight:

[0127] 20~30 mesh quartz sand 19kg

[0128] 30~40 mesh quartz sand 38kg

[0129] 40~70 mesh quartz sand 28kg

[0130] Fly ash 20kg

[0131] Barite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com