Chemical nickel plating solution for flexible printed circuit board and plating construction method thereof

A flexible circuit board, chemical nickel plating technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve serious alloy coating cracks, affect the ductility and corrosion resistance of the coating, nickel-phosphorus alloy coating Problems such as cracks are prone to occur, and the effect of improving bending resistance and corrosion resistance is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A solution for electroless nickel plating on flexible circuit boards, the formula is:

[0049] Nickel sulfate 22.5 g / l,

[0050] Sodium hypophosphite 30.0 g / l,

[0051] Lactic acid (88%) 15.0 g / l,

[0052] Malic acid 12.0 g / l,

[0053] Sodium acetate 8.0 g / l,

[0054] Ethylenediamine 5.0 g / l,

[0055] Thiodiacetic acid 2.0ppm;

[0056] The method for applying plating on the surface of a flexible printed circuit board using the above-mentioned nickel plating solution comprises the following steps:

[0057] (1) Grinding plate sandblasting; after grinding the plate, remove the residue on the copper surface, and sandblasting to make the copper surface uniform;

[0058] (2) Degreasing: Degrease the circuit board with an acid degreaser or alkaline degreaser to remove organic matter and oxides on the copper surface. The degreasing time is 5 minutes, and wash with water after completion;

[0059](3) Microetching: immerse the circuit board treated in step (2) in the mixtu...

Embodiment 2

[0069] A solution for electroless nickel plating on flexible circuit boards, the formula is:

[0070] Nickel sulfate 22.5 g / l,

[0071] Sodium hypophosphite 30.0 g / l,

[0072] Lactic acid (88%) 15.0 g / l,

[0073] Malic acid 12.0 g / l,

[0074] Sodium acetate 8.0 g / l,

[0075] Triethylenetetramine 5.0 g / l,

[0076] Allylthiourea 2.0ppm,

[0077] The pH value of the solution was controlled at 4.6, and the temperature was controlled at 85°C.

[0078] The method for applying plating on the surface of a flexible printed circuit board using the above-mentioned nickel plating solution, the steps are the same as in Example 1.

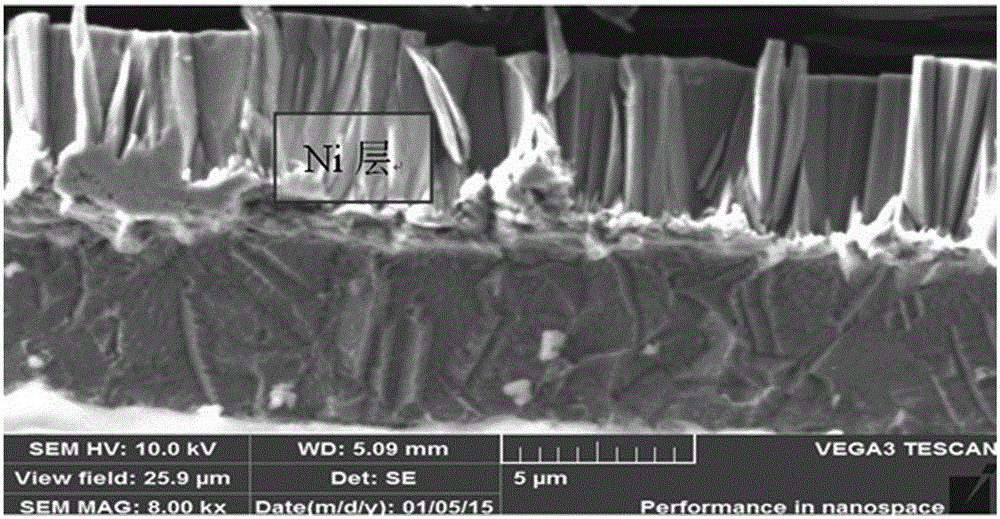

[0079] Dip the circuit board in gold-removing water containing 100 g / L NaCN for 10 seconds, wash it with water, dry the surface, bend it 180 degrees, observe the side of the nickel alloy layer with a scanning electron microscope, the nickel alloy layer has a columnar structure, and the nickel layer has no fracture ;

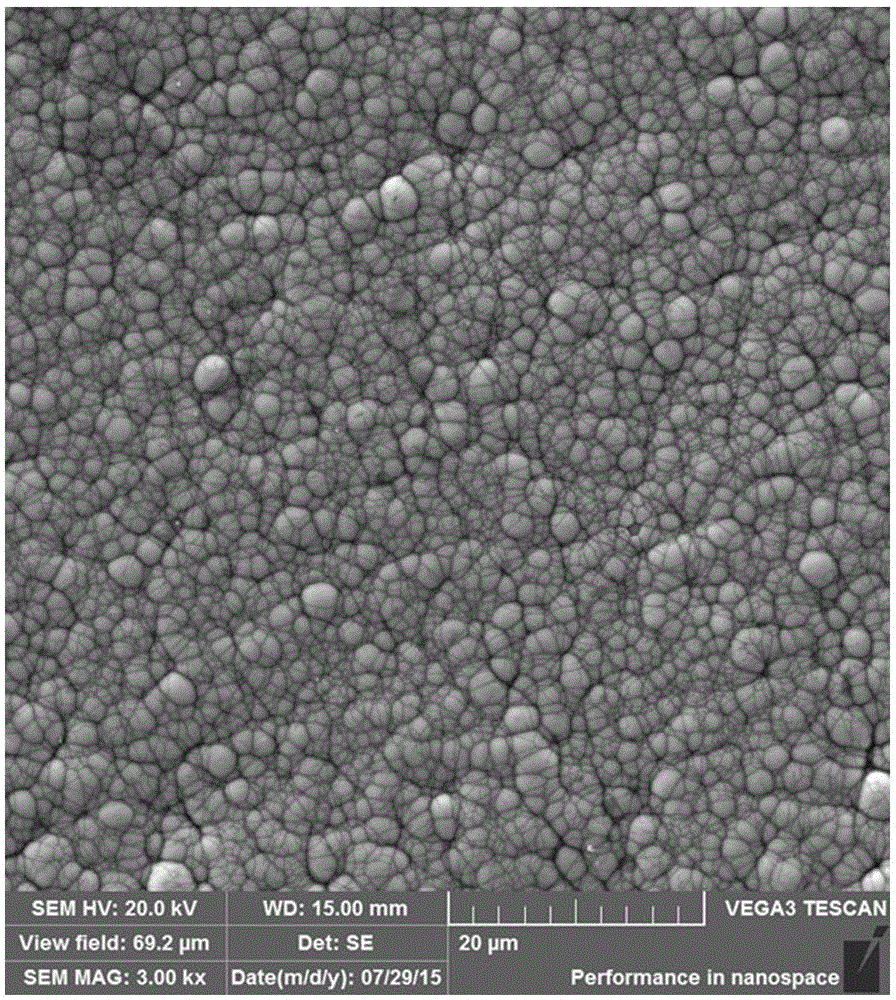

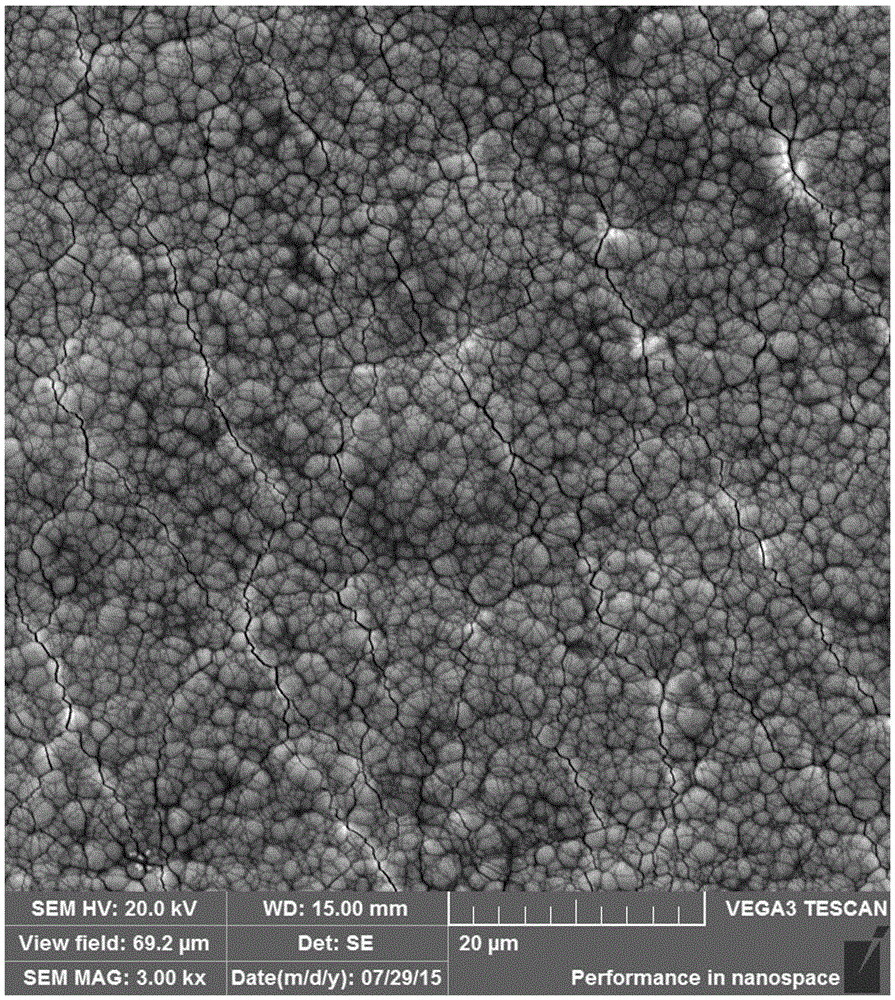

[0080] Observing the surface of the ...

Embodiment 3

[0082] A solution for electroless nickel plating on flexible circuit boards, the formula is:

[0083] Nickel sulfate 30 g / l,

[0084] Sodium hypophosphite 40 g / l,

[0085] Lactic acid (88%) 10 g / l,

[0086] Malic acid 20 g / l,

[0087] Sodium acetate 15 g / l,

[0088] Hexamethylenetetramine 0.5 g / l,

[0089] 2-aminothiazole 2.0 ppm;

[0090] The pH value of the solution was controlled at 4.6, and the temperature was controlled at 85°C.

[0091] The method for applying plating on the surface of a flexible printed circuit board using the above-mentioned nickel plating solution, the steps are the same as in Example 1.

[0092] Immerse the circuit board in gold-removing water containing 70 g / L NaCN for 15 seconds, wash it with water, dry the surface, and bend it 180 degrees. Observe the side of the nickel alloy layer with a scanning electron microscope. The nickel alloy layer has a columnar structure, and the nickel layer has no fracture;

[0093] Observing the surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com