A kind of molding process of polystyrene pipe

A technology of polystyrene molding process, which is applied in the field of polystyrene pipe molding technology, can solve the problems of pipe rigidity, flexibility, low stability, and complicated process, so as to improve the comprehensive mechanical properties, simplify the molding process, and reduce the production cost. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] The invention provides a new technology for making polystyrene pipes. The raw materials used include polystyrene recycled crushed material, toughening agent, HDPE (high density polyethylene) crushed material, filler, EBS (ethylene bishard Fatty amide), antioxidant, coupling agent, stearic acid. The ratio of parts of various components is as follows:

[0031] Polystyrene recycled crushed material: 80-90

[0032] Toughener: 2~4

[0033] HDPE broken material: 3~5

[0034] Filling: 4~6

[0035] EBS: 0.2~0.5

[0036] Antioxidant: 0.2~0.5

[0037] Coupling agent: 0.4~3.5

[0038] Stearic acid: 0.2 to 0.5.

[0039] Among the above components, the toughening agent can be SBS or SEBS; the filler can be talcum powder, or it can be obtained by mixing wollastonite and talc powder in a ratio of 1:2.

[0040] The coupling agent is preferably a titanate coupling agent (the addition ratio of titanate is 2%); and the antioxidant is preferably antioxidant 1010.

[0041] Accordin...

example 1

[0052] The various raw materials used in this example have the ratios of parts: polystyrene recycled crushed material: 90 parts, SBS: 2 parts, HDPE crushed material: 3 parts, talcum powder: 4 parts, EBS: 0.2 parts, anti- Oxygen agent: 0.2 parts, coupling agent: 0.4 parts, stearic acid: 0.2 parts.

example 2

[0054] The various raw materials used in this example have the following ratios: polystyrene recycled crushed material: 80 parts, SEBS: 4 parts, HDPE crushed material: 5 parts, wollastonite: 2 parts, talcum powder: 4 parts , EBS: 0.5 parts, antioxidant: 0.5 parts, coupling agent: 3.5 parts, stearic acid: 0.5 parts.

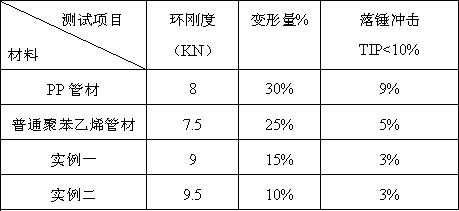

[0055] Table 1 shows the performance comparison of pipes made of special materials obtained from the components of Example 1 and Example 2 with PP pipes and ordinary polystyrene pipes. The comparison parameters also include ring stiffness, deformation, and TIP.

[0056]

[0057] Table 1

[0058] As can be seen from Table 1, compared with PP pipes and common polystyrene pipes, the use of Example 1 and Example 2 of the present invention has obvious advantages in various technical parameters. The TIP value of rigidity (ring stiffness), flexibility (deformation) and drop hammer impact of the polystyrene pipe made by the present invention has been significantly opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com