Treatment method of uranium-containing waste water

A treatment method and wastewater technology, which is applied in nuclear engineering, radioactive purification, etc., can solve the problems of equipment corrosion solution treatment, complicated process flow, and increased costs, and achieve the effects of reducing water environmental protection pressure, improving removal efficiency, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1: the treatment of uranium-containing wastewater

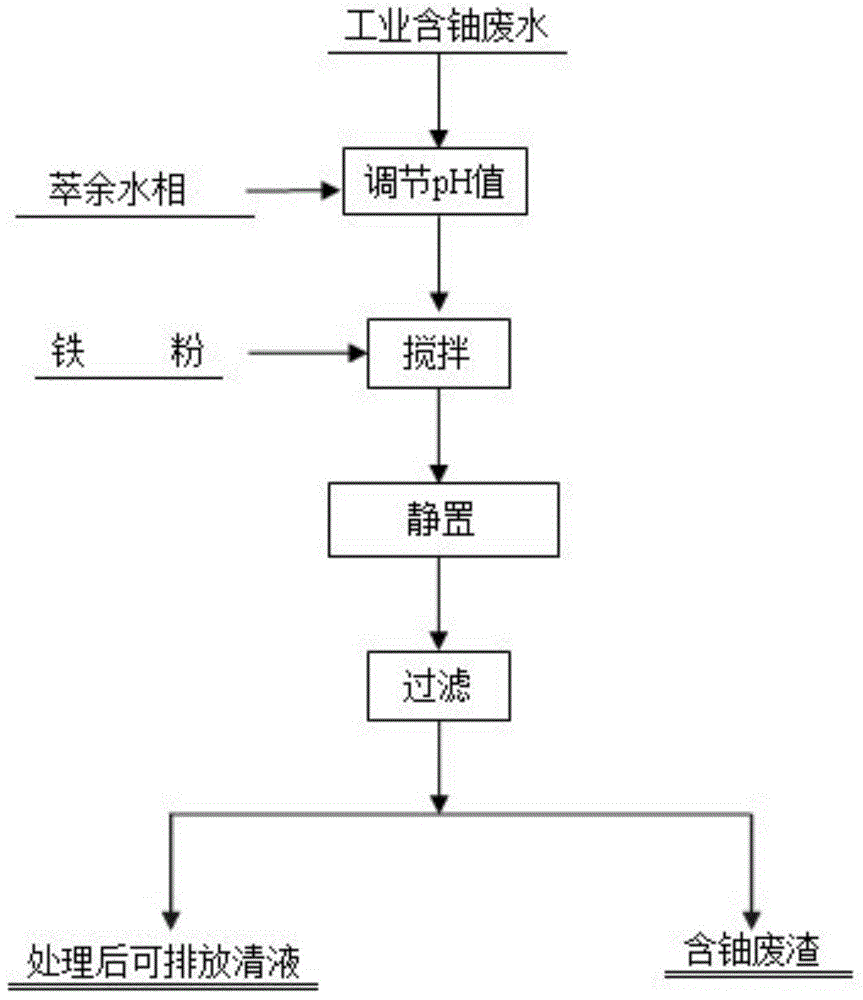

[0054] The specific processing flow of this embodiment is as attached figure 1 shown. The implementation steps of this embodiment are as follows:

[0055] A. Adjust the pH value

[0056] Under the condition of stirring, add the uranium concentration of 2000μg / L and pH 1.0 from the uranium extraction section to the industrial uranium-containing wastewater from the uranium ore leaching to remove solid impurities. For the remaining aqueous phase, adjust the pH value of the industrial uranium-containing wastewater to 3.6 to obtain a pH-adjusted industrial uranium-containing wastewater;

[0057] B. Add iron powder

[0058] According to the ratio of industrial uranium-containing wastewater in liters and iron powder in grams is 7:1, adding zero-valent iron content to 50% and 80 mesh iron powder in the industrial uranium-containing wastewater obtained in step A to adjust pH, In the reactor, the reaction was car...

Embodiment 2

[0061] Embodiment 2: the treatment of uranium-containing wastewater

[0062] The specific processing flow of this embodiment is as attached figure 1 shown. The implementation steps of this embodiment are as follows:

[0063] A. Adjust the pH value

[0064] Under stirring conditions, add uranium concentration of 12000 μg / L, The raffinate aqueous phase with a pH of 0.8, the pH value of the industrial uranium-containing wastewater is adjusted to 5.4 to obtain a pH-adjusted industrial uranium-containing wastewater;

[0065] B. Add iron powder

[0066] According to the ratio of industrial uranium-containing wastewater in liters and iron powder in grams is 10:1, adding zero-valent iron content to 98% and 90 mesh iron powder in the industrial uranium-containing wastewater obtained in step A to adjust pH, In the reactor, the reaction was carried out for 130min at room temperature and under the condition of stirring at a stirring rate of 500rpm to obtain a kind of iron powder trea...

Embodiment 3

[0069] Embodiment 3: the treatment of uranium-containing wastewater

[0070] The specific processing flow of this embodiment is as attached figure 1 shown. The implementation steps of this embodiment are as follows:

[0071] A. Adjust the pH value

[0072] Under the condition of stirring, add the uranium concentration of 500μg / L and pH 0.2 from the uranium extraction section to the industrial uranium-containing wastewater with a uranium concentration of 12000μg / L and a pH of 10 from the extraction and separation of uranium leachate to remove solid impurities. For the remaining aqueous phase, adjust the pH value of the industrial uranium-containing wastewater to 3.0 to obtain a pH-adjusted industrial uranium-containing wastewater;

[0073] B. Add iron powder

[0074] According to the ratio of industrial uranium-containing wastewater in liters and iron powder in grams is 3:1, adding zero-valent iron content to 60% and 120 mesh iron powder in the industrial uranium-containing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com