An automatic detection method for the abundance of butane-oxidizing bacteria

A technology for automatic detection and oxidizing bacteria, applied in biochemical equipment and methods, microbial determination/inspection, etc., can solve problems such as inability to find, inability to carry out systems, and low efficiency, avoiding human errors, and realizing unified calibration and data. Reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

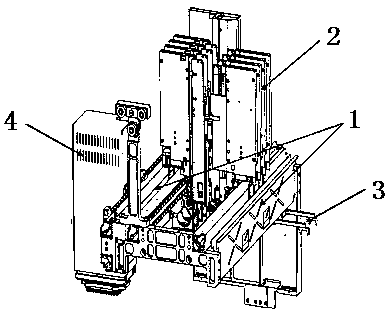

[0060] This embodiment provides an automatic processing device for original state microbial oil gas and hydrate exploration technology, including automatic liquid processing device and nucleic acid extraction and purification equipment;

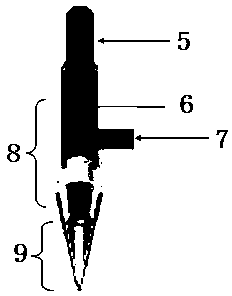

[0061] The automatic liquid processing device automatically adds samples, prepares and processes samples and reaction reagents, and puts the entire experimental process in an unmanned environment by integrating various terminal analysis and detection equipment to run fully automatically and give results. Preferably, the automatic liquid processing device is composed of four parts: an operating platform, a mechanical arm, a pipetting channel, and a carrier and auxiliary equipment for experimental supplies; several positioning tracks (T) are arranged on the operating platform, It is used to fix the carrier for various experimental supplies. The operating platform is the frame of the entire workstation, which is a semi-closed structure. There is...

Embodiment 2

[0070] Based on the automatic sample processing device of the original state microbial oil gas and hydrate exploration technology described in the present invention, this embodiment provides an automatic workstation for the original state microbial oil gas and hydrate exploration technology, and the workstation includes the original state microbial oil gas and hydrate The automatic processing sample device for exploration technology also includes laminar flow hood and PCR reaction system configuration system.

[0071] An ultra-clean laminar flow hood is set above the automatic liquid processing device and / or nucleic acid extraction and purification equipment to ensure a sterile working environment; a ventilation pipeline can also be connected to discharge or recycle harmful substances generated in the experiment. Such a setting can not only protect the health and safety of operators, but also ensure the safety of samples and experimental procedures.

[0072] Based on the autom...

Embodiment 4

[0141] Embodiment 4 Automated Workstation Work Performance Test of the present invention

[0142] 1. Sample processing capacity

[0143] Summarize from the detection system operation record of the present invention, the start time of processing 96 marine sediment parallel samples is 11:06:26 seconds, and the end time is 12:46:03 seconds, about 1 hour and 40 minutes (i.e. 100 minutes) minutes); the detection system of the present invention runs for 8 hours per day, then the number of samples that can be processed every day=(8 hours×60 minutes / hour)×96 / 100 minutes]=461; the annual running time is calculated by 300 days, then this The invention detection system can handle 138,300 samples per year.

[0144] 2. The effect of extracting nucleic acid

[0145] From the 96 nucleic acid samples obtained above, 9 samples were arbitrarily selected for PCR amplification, and its electrophoresis was as follows: Figure 4 shown. In order to compare the effect of nucleic acid extraction, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com