Interface metallurgical bonding aluminum foam slab and preparation method thereof

A foamed aluminum plate and interface metallurgy technology, applied in chemical instruments and methods, metal layered products, lamination, etc., can solve problems such as large influence, complex process equipment, adhesive deactivation and aging, and improve stability , The effect of simple process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

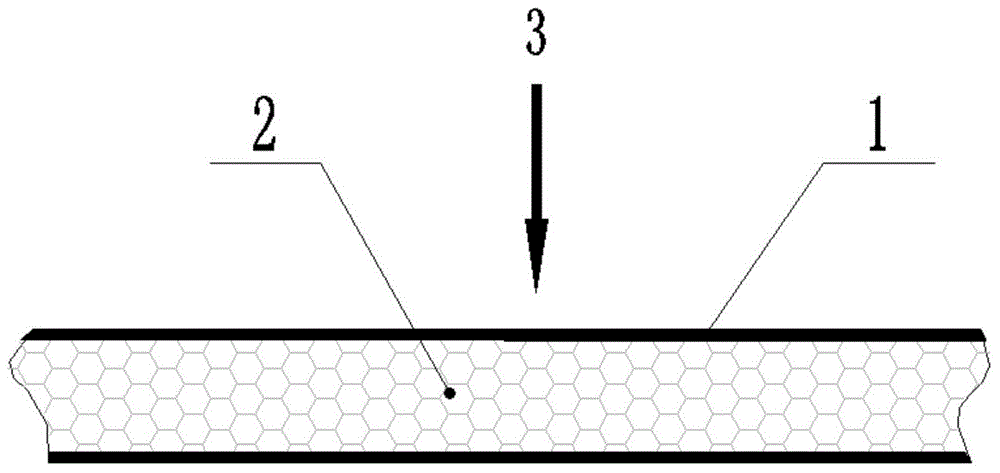

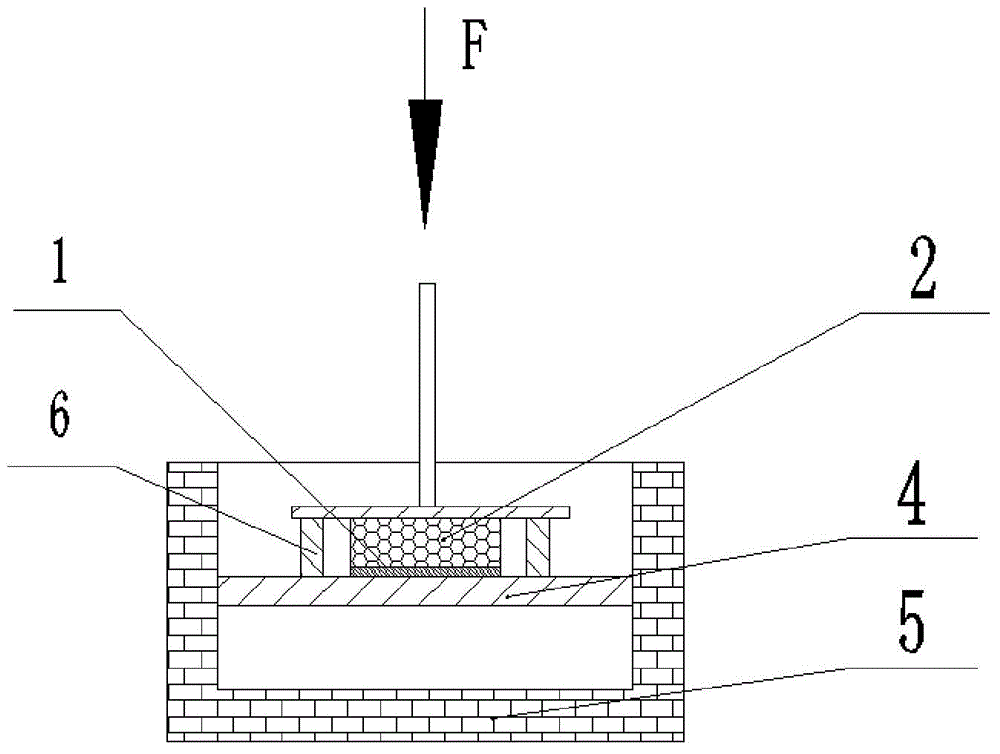

[0023] The density prepared by the melt foaming method is 0.15g / cm 3 1. A foamed aluminum plate with a thickness of 5mm and uniform porosity, remove the burrs with a steel brush, a brush, etc., and blow the surface of the foamed aluminum plate with compressed air with a pressure of not less than 0.5MPa. Place the surface-treated foamed aluminum plate in the interface heating furnace. The surface of the foamed aluminum core layer plate to be treated is placed on the interface heating platform of the interface heating furnace for heating. The interface heating platform is a high-temperature resistant steel plate, and the surface layer of the high-temperature-resistant steel plate is brushed. Apply zinc oxide paint, heat the temperature to 1150°C, place the limit block on the heated aluminum foam core sheet to control the thickness of the skin, and apply a static pressure of 1.0Mpa to the limit block evenly through a pressure machine. The surface of the aluminum foam core layer p...

Embodiment 2

[0025] The density prepared by the melt foaming method is 1.0g / cm 3 1. A foamed aluminum plate with a thickness of 380mm and uniform porosity, remove burrs with steel brushes, brushes, etc., and blow the surface of the foamed aluminum plate with compressed air with a pressure of not less than 0.5MPa. Place the surface-treated foamed aluminum plate in the interface heating furnace. The surface of the foamed aluminum core layer plate to be treated is placed on the interface heating platform of the interface heating furnace for heating. The interface heating platform is a high-temperature resistant steel plate, and the surface layer of the high-temperature-resistant steel plate is brushed. Apply zinc oxide paint, heat the temperature to 1250°C, place the limit block on the heated aluminum foam core sheet to control the thickness of the skin, and apply a static pressure of 5.0Mpa to the limit block evenly through a pressure machine. One surface of the aluminum foam core sheet form...

Embodiment 3

[0027] The density prepared by the melt foaming method is 0.55g / cm 3 1. A foamed aluminum plate with a thickness of 150mm and uniform porosity, remove burrs with steel brushes, brushes, etc., and blow the surface of the foamed aluminum plate with compressed air with a pressure of not less than 0.5MPa. Place the surface-treated foamed aluminum plate in the interface heating furnace. The surface of the foamed aluminum core layer plate to be treated is placed on the interface heating platform of the interface heating furnace for heating. The interface heating platform is a high-temperature resistant steel plate, and the surface layer of the high-temperature-resistant steel plate is brushed. Apply zinc oxide paint, heat the temperature to 1200°C, place the limit block on the heated aluminum foam core sheet to control the thickness of the skin, and apply a static pressure of 3.5Mpa to the limit block evenly through a pressure machine. One surface of the aluminum foam core sheet for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com