High-performance wood-based composite pressure conveyer pipe and preparation method

A high-performance, conveying pipe technology, applied in the field of pipelines, can solve the problems of transportation, inconvenient installation, high energy consumption, environmental pollution, etc., and achieve the effect of improving gluing quality and production efficiency, improving comprehensive benefits, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

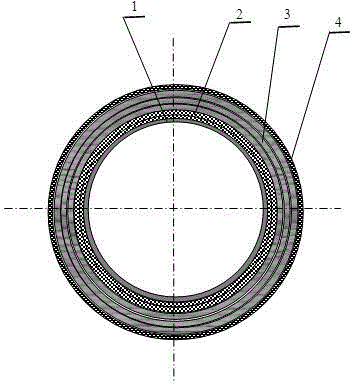

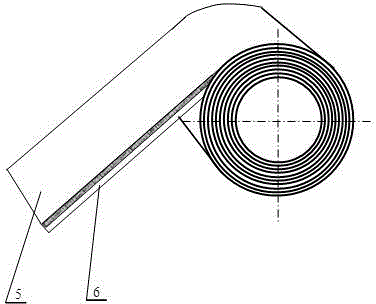

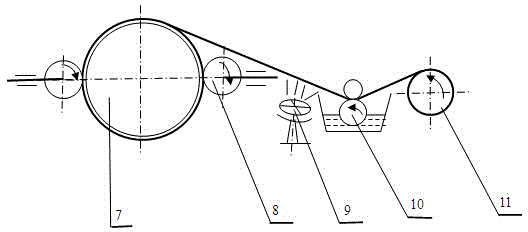

[0039] control figure 1 , The high-performance wood-based composite pressure delivery pipe with a diameter of 300mm is made of carbon fiber as a reinforced material. The structure from the inside to the outside is: inner lining layer 1, reinforcement layer 2, wood layer 3, and outer protective layer 4. Its preparation process is as follows:

[0040](1) Preparation of the inner lining layer: evenly coat a layer of butter and a release agent with equivalent performance on the straight tube mold with a taper of 3:1000, wrap the PET film, and coat the surface of the film with vinyl ester resin immediately after covering the surface felt , Coat a layer of vinyl ester resin and then cover chopped strand mat and grid cloth. After the resin is cured, an inner lining layer with anti-seepage and smooth inner wall is formed. The thickness of the inner lining layer is about 3mm. The resin grade is anti-corrosion grade or food grade ;

[0041] (2) Preparation of reinforcing layer materia...

Embodiment 2

[0046] control figure 1 ., using carbon fiber as a reinforced material to manufacture a high-performance wood-based composite pressure delivery pipe with a diameter of 600mm, its structure is the same as in the examples, and the preparation process is as follows:

[0047] (1) lining layer preparation: same as embodiment 1;

[0048] (2) preparation of strengthening layer material: same as embodiment 1;

[0049] (3) Preparation of woody base layer material: Rotate wood sections into wood veneers with a thickness of 1.2mm, dry to a moisture content of 8%; according to the method for making wood plywood, coat one side of the wood veneer with phenolic or equivalent performance Adhesive, longitudinal veneer and horizontal veneer texture staggered blanks, or textured 85° blanks, pressurized and glued to form a wooden plywood with an asymmetric structure, the thickness is about 2.1mm; saw the wooden plywood into fixed width The slats are then milled into bevels with a bevel milling ...

Embodiment 3

[0053] A high-performance wood-based composite pressure delivery pipe with a diameter of 400mm was manufactured with aluminum alloy as a reinforced material, and its structure was the same as in Example 1. The preparation process was as follows:

[0054] (1) lining layer preparation: same as embodiment 1;

[0055] (2) Preparation of reinforcing layer material: Aluminum alloy thin plate with a thickness of 0.5mm is cut into a strip with a width of 250mm and a length designed according to the length of the tube, and is rolled up for later use;

[0056] (3) Preparation of woody base layer material: Rotate wood sections into wood veneers with a thickness of 1.0mm, and dry to a moisture content of 8%; according to the method for making wood plywood, one side of the wood veneer is coated with phenolic or equivalent performance. Adhesive, vertical veneer and horizontal veneer staggered billet, or textured 85° billet, pressurized and glued to form a wooden plywood with an asymmetric s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com