PBT (polybutylece terephthalate) engineering plastic composition used for NMT (Nano Molding Technology)

A technology of engineering plastics and compositions, applied in the field of engineering plastics, can solve the problems of poor rigidity, low notched impact strength, low thermal deformation temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

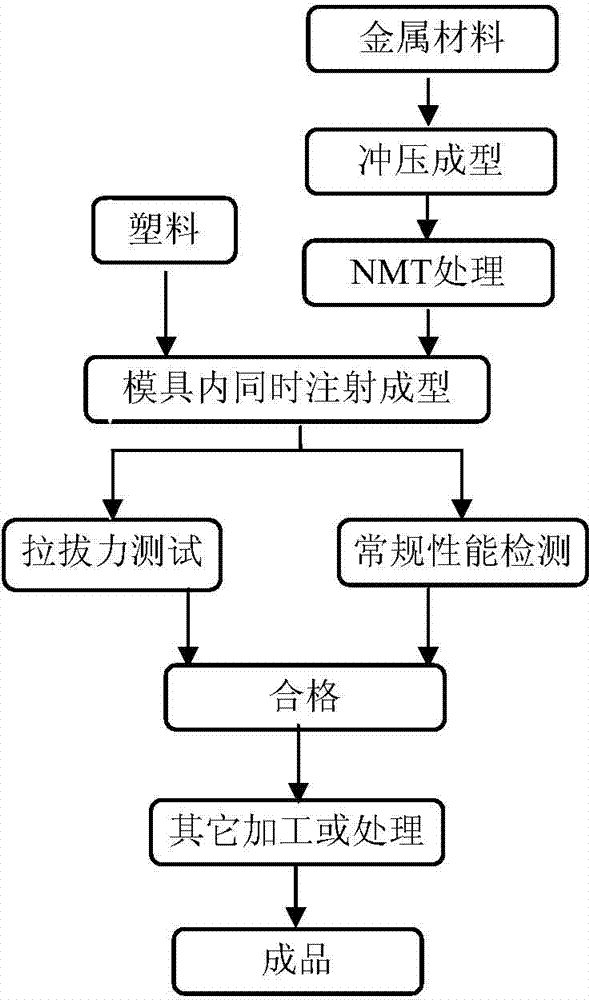

Method used

Image

Examples

Embodiment 1

[0083] Embodiment 1: the PBT engineering plastics composition that is used for NMT technology of the present embodiment, by mass parts, comprises the following components:

[0084]

[0085] Among them, the intrinsic viscosity of PBT is 1.0g / dL, the intrinsic viscosity of PET is 0.82g / dL, the glass fiber is Owens Corning's 183F, and the toughening agent is ethylene / methyl acrylate copolymer and maleic anhydride copolymer. It can be toughening agent 35BA40 and toughening agent 4700, the quality of the two is 1:1.

[0086] The above-mentioned PBT engineering plastic composition preparation method for NMT technology is as follows:

[0087] In terms of parts by mass, 60 parts of PBT resin, 10 parts of PET resin, 8 parts of toughening agent, 1 part of antioxidant, 1.1 part of heat stabilizer, 0.5 part of polyethylene wax and 0.3 part of pentaerythritol stearate were pre-mixed uniformly get the mixture;

[0088] 15 parts of the mixture and glass fibers were put into an extruder ...

Embodiment 2

[0089] Embodiment 2: the PBT engineering plastics composition that is used for NMT technology of the present embodiment, by mass parts, comprises the following components:

[0090]

[0091] Among them, the intrinsic viscosity of PBT in this embodiment is 1.0g / dL, the intrinsic viscosity of PET is 0.82g / dL, the glass fiber is Owens Corning's 183F, and the toughening agent is ethylene / methyl acrylate copolymer and maleic acid The acid anhydride copolymer can be toughening agent 35BA40 and toughening agent 4700, and the quality of the two is 1:1.

[0092] The above-mentioned preparation method of the PBT engineering plastics composition that is used for NMT technology is as follows:

[0093] In parts by mass, 60 parts of PBT resin, 16 parts of PET resin, 4 parts of toughening agent 35BA40, 4 parts of toughening agent 4700, 1 part of antioxidant, 1.1 parts of thermal stabilizer, 1 part of polyethylene wax, pentaerythritol stearin 0.3 parts of acid ester and 0.5 parts of nuclea...

Embodiment 3

[0095] Embodiment 3: The PBT engineering plastics composition that is used for NMT technology of the present embodiment, by mass parts, comprises the following components:

[0096]

[0097] Among them, the intrinsic viscosity of PBT is 1.0g / dL, the intrinsic viscosity of PET is 0.82g / dL, the glass fiber is 183F of Owens Corning, and the toughening agent is glycidyl methacrylate copolymer and methacrylic acid copolymer And maleic anhydride copolymer, can be toughening agent AX8900, toughening agent 3990 and toughening agent 8200, the molar ratio of the glycidyl methacrylate functional group and the sum of carboxyl functional group and acid anhydride functional group in the above-mentioned toughening agent is at 1 : 0.6.

[0098] The preparation method of the PBT engineering plastic composition used in the NMT technology in this embodiment is the same as that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com