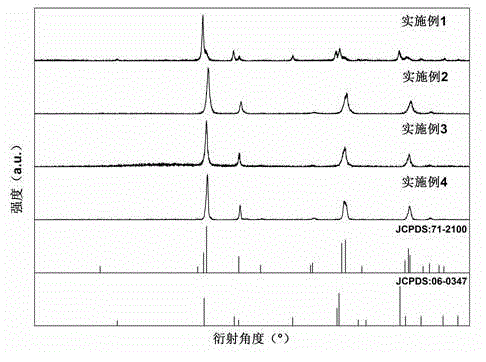

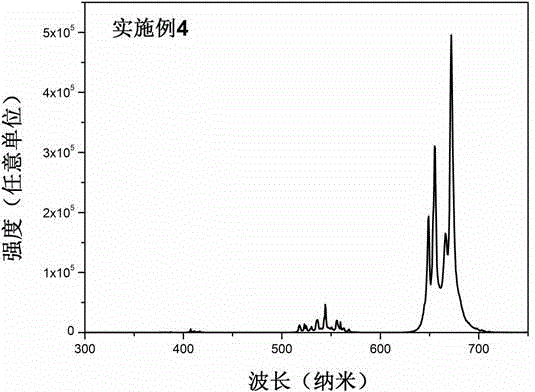

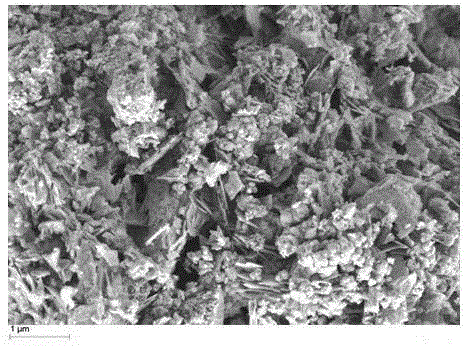

Preparation method of Er<3+> and Yb<3+> co-doped YOF red up-conversion fluorescent material

A fluorescent material, red technology, applied in the field of Er3+, can solve the problems of poor mechanical strength and chemical stability, harsh control of experimental technical conditions, and high equipment requirements, and achieves good up-conversion performance, not harsh preparation conditions, and low heat treatment temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Weigh 0.306g solid powder yttrium nitrate hexahydrate, 0.076g solid powder ytterbium nitrate pentahydrate, and 0.013g solid powder erbium nitrate pentahydrate;

[0035] 2) Measure 4ml of isopropanol, 4ml of ethanol, 1ml of trifluoroacetic acid, and 3ml of water, add solid powder into it, stir for 3 hours, and obtain transparent sol A;

[0036] 3) Transfer transparent sol A to a high-temperature-resistant crucible, and dry in an oven for 3 hours to obtain colloidal substance B;

[0037] 4) Put the colloidal substance B in a high-temperature furnace, raise the temperature of the furnace from room temperature to 350 °C at a rate of 4 °C / min, keep it warm for 1 hour, and take it out after cooling to room temperature with the furnace;

[0038] 5) Grinding to get Er 3+ ,Yb 3+ Co-doped YOF powder.

Embodiment 2

[0040] 1) Weigh 0.306g solid powder yttrium nitrate hexahydrate, 0.076g solid powder ytterbium nitrate pentahydrate, and 0.013g solid powder erbium nitrate pentahydrate;

[0041] 2) Measure 4ml of isopropanol, 4ml of ethanol, 1ml of trifluoroacetic acid, and 3ml of water, add solid powder into it, stir for 3 hours, and obtain transparent sol A;

[0042] 3) Transfer transparent sol A to a high-temperature-resistant crucible, and dry in an oven for 3 hours to obtain colloidal substance B;

[0043] 4) Put the colloidal substance B in a high-temperature furnace, raise the temperature of the furnace from room temperature to 400 °C at a rate of 4 °C / min, keep it warm for 1 hour, and take it out after cooling to room temperature with the furnace;

[0044] 5) Grinding to get Er 3+ ,Yb 3+ Co-doped YOF powder.

Embodiment 3

[0046] 1) Weigh 0.306g solid powder yttrium nitrate hexahydrate, 0.076g solid powder ytterbium nitrate pentahydrate, and 0.013g solid powder erbium nitrate pentahydrate;

[0047] 2) Measure 4ml of isopropanol, 4ml of ethanol, 1ml of trifluoroacetic acid, and 3ml of water, add solid powder into it, stir for 3 hours, and obtain transparent sol A;

[0048] 3) Transfer transparent sol A to a high-temperature-resistant crucible, and dry in an oven for 3 hours to obtain colloidal substance B;

[0049] 4) Put the colloidal substance B in a high-temperature furnace, raise the temperature of the furnace from room temperature to 500 °C at a rate of 4 °C / min, keep it warm for 1 hour, and take it out after cooling to room temperature with the furnace;

[0050] 5) Grinding to get Er 3+ ,Yb 3+ Co-doped YOF powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com