A preparation method of rare earth ion doped yttrium fluoride green up-conversion fluorescent material

A technology of rare earth ions and fluorescent materials, applied in the field of preparation of rare earth doped luminescent materials, can solve the problems of harsh experimental technical conditions control, unfavorable large-scale industrial production, and difficult to guarantee purity, and achieves good up-conversion performance and equipment. The effect of low cost and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

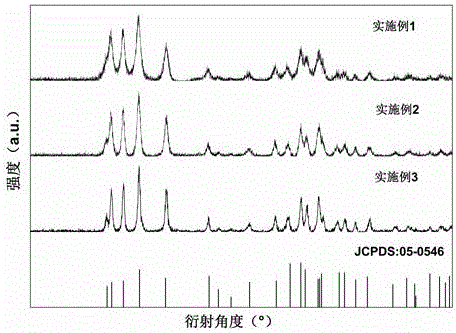

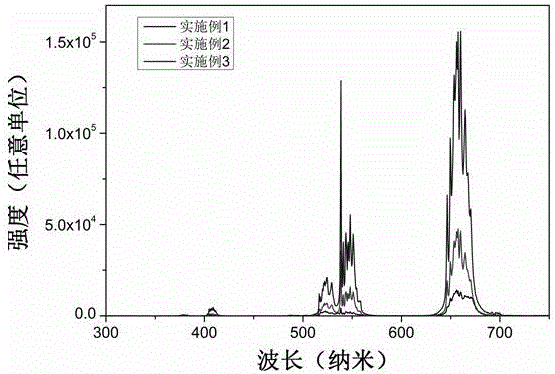

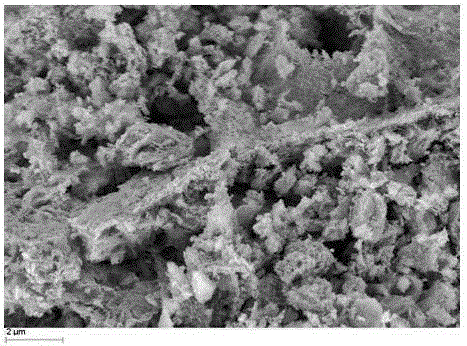

Embodiment 1

[0030] 1) Weigh 0.306g solid powder yttrium acetate hexahydrate, 0.076g solid powder ytterbium acetate pentahydrate, and 0.013g solid powder erbium acetate pentahydrate;

[0031] 2) Measure 4ml of isopropanol, 4ml of ethanol, 1ml of trifluoroacetic acid, and 3ml of water, add solid powder into it, stir for 3 hours, and obtain transparent sol A;

[0032] 3) Transfer transparent sol A to a high-temperature-resistant crucible, and dry in an oven for 3 hours to obtain colloidal substance B;

[0033] 4) Put the colloidal substance B in a high-temperature furnace, raise the temperature of the furnace from room temperature to 300 °C at a rate of 4 °C / min, keep it for 1 hour, and take it out after cooling to room temperature with the furnace;

[0034] 5) Grinding to get YF 3 : Yb 3+ , Er 3+ powder.

Embodiment 2

[0036] 1) Weigh 0.306g solid powder yttrium acetate hexahydrate, 0.076g solid powder ytterbium acetate pentahydrate, and 0.013g solid powder erbium acetate pentahydrate;

[0037] 2) Measure 4ml of isopropanol, 4ml of ethanol, 1ml of trifluoroacetic acid, and 3ml of water, add solid powder into it, stir for 3 hours, and obtain transparent sol A;

[0038] 3) Transfer transparent sol A to a high-temperature-resistant crucible, and dry in an oven for 3 hours to obtain colloidal substance B;

[0039] 4) Put the colloidal substance B in a high-temperature furnace, raise the temperature of the furnace from room temperature to 400 °C at a rate of 4 °C / min, keep it warm for 1 hour, and take it out after cooling to room temperature with the furnace;

[0040] 5) Grinding to get YF 3 : Yb 3+ , Er 3+ powder.

Embodiment 3

[0042] 1) Weigh 0.306g solid powder yttrium acetate hexahydrate, 0.076g solid powder ytterbium acetate pentahydrate, and 0.013g solid powder erbium acetate pentahydrate;

[0043] 2) Measure 4ml of isopropanol, 4ml of ethanol, 1ml of trifluoroacetic acid, and 3ml of water, add solid powder into it, stir for 3 hours, and obtain transparent sol A;

[0044] 3) Transfer transparent sol A to a high-temperature-resistant crucible, and dry in an oven for 3 hours to obtain colloidal substance B;

[0045] 4) Put the colloidal substance B in a high-temperature furnace, raise the temperature of the furnace from room temperature to 500 °C at a rate of 4 °C / min, keep it warm for 1 hour, and take it out after cooling to room temperature with the furnace;

[0046] 5) Grinding to get YF 3 : Yb 3+ , Er 3+ powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com