Antibacterial Modification Method of Silicone Rubber

An antibacterial, silicone rubber technology, applied in the field of antibacterial modification of medical silicone rubber, can solve the problems of unstable surface groups, complicated control and steps, complicated steps, etc., and achieves improved biocompatibility and operation. The effect of easy control of conditions and good antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The antibacterial modification of embodiment 1 silicone rubber

[0032] Taking medical silicone rubber as the material to be treated, four groups of medical silicone rubber were selected and marked as Ag1-SR, Ag2-SR, Ag3-SR and SR; The SR, Ag2-SR and Ag3-SR groups were treated with ion dose of 5×10 15 ions / cm 2 , 20×10 15 ions / cm 2 and 50×10 15 ions / cm 2 Perform ion implantation, the ion energy of the Ag ion is 10keV, and the parameter beam current density is set during the ion implantation process is not greater than 1mA / cm 2 , the residual air pressure is not greater than 1×10 -4 Pa, after processing, three groups of antibacterial silicone rubbers are obtained.

Embodiment 2

[0033] Embodiment 2 antibacterial silicone rubber scanning electron microscope detection result

[0034] Ag1-SR, Ag2-SR and Ag3-SR group antimicrobial silicone rubber and SR control group silicone rubber prepared by embodiment 1 are observed and analyzed under scanning electron microscope respectively, and the results are as follows: figure 1 shown by figure 1 It can be seen that under the magnification of 10000 times, there is no difference between the antibacterial silicone rubber Ag ion implantation of the Ag1-SR, Ag2-SR and Ag3-SR groups and the control group silicone rubber SR, indicating that the impact of the Ag ion implantation on the surface structure of the material Change is on a more microscopic scale.

Embodiment 3

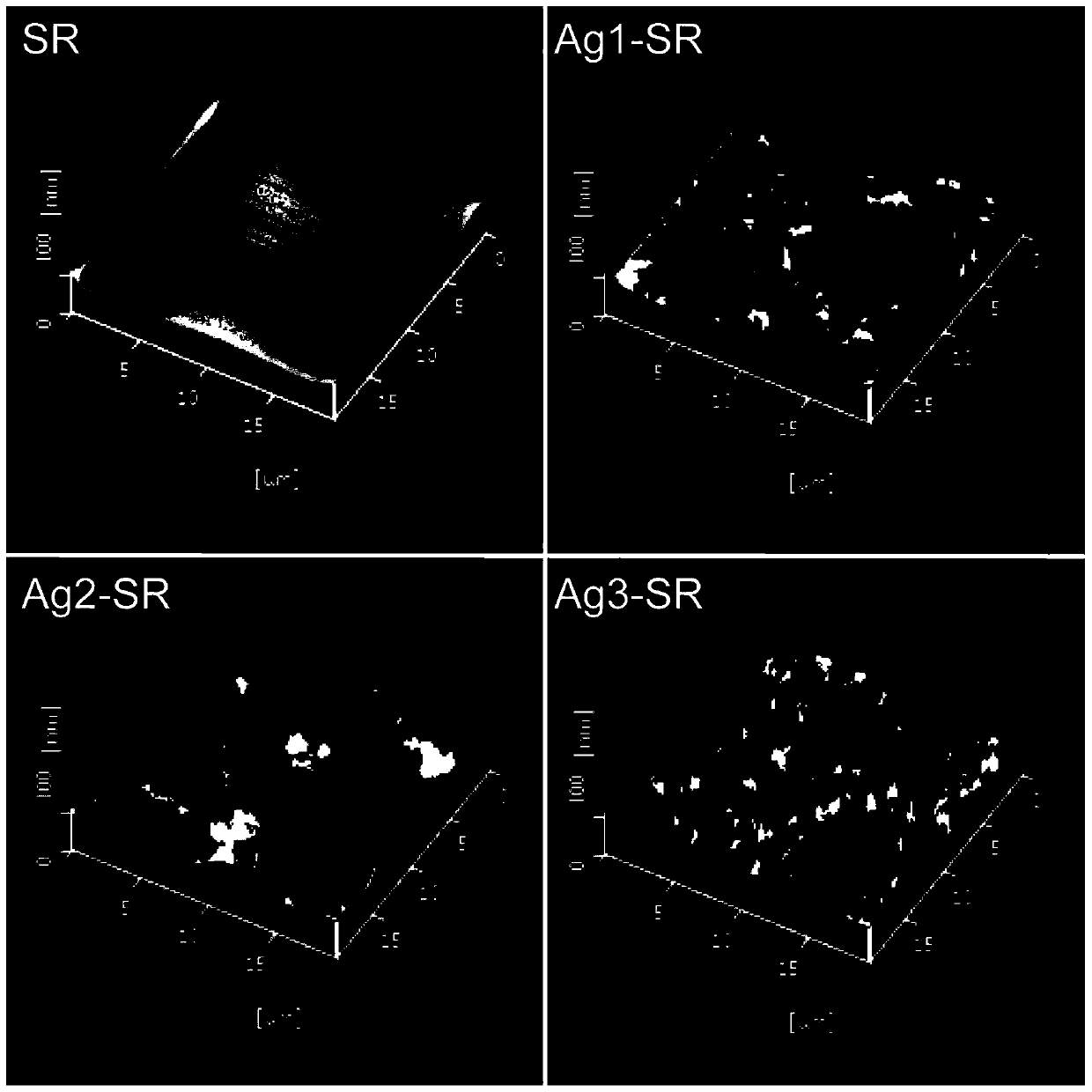

[0035] Embodiment 3 antibacterial silicone rubber atomic force microscope detection result

[0036] Ag1-SR, Ag2-SR and Ag3-SR group antimicrobial silicone rubber and SR control group silicone rubber prepared by embodiment 1 are carried out atomic force microscope detection and analysis respectively, the result is as follows figure 2 shown by figure 2 It can be seen that the atomic force microscope is used to analyze and observe from the atomic level that the Ag1-SR, Ag2-SR and Ag3-SR groups have differences in the antibacterial silicone rubber Ag ion implantation and the control silicone rubber SR, and the surface roughness of the silicone rubber after ion implantation The increase indicates that after Ag ion implantation, the change of the surface structure of the material belongs to the atomic level.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com