Preparation method of bilobalide B and bilobalide B prepared therefrom

A technology of ginkgolide and ginkgo biloba, which is applied in the field of natural medicinal chemistry, can solve the problems of high equipment requirements, no industrial application value, unsuitable for large-scale industrial production, and the like, and achieves the effect of improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

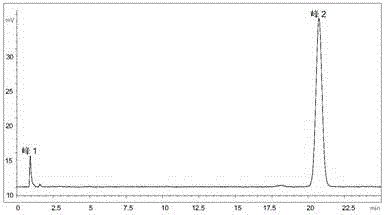

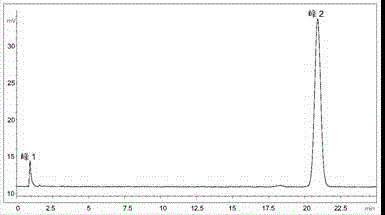

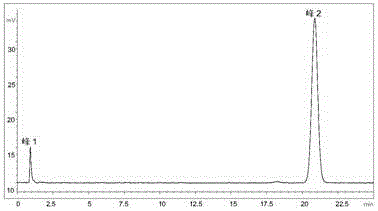

Image

Examples

Embodiment 1

[0041] Ginkgo biloba 150kg, pulverized, with 10 times (ratio of ethanol volume (ml) and ginkgo biloba weight (g), V / W) 70% ethanol heating reflux extraction 2 times, each time 2 hours, combined extracts, concentrated under reduced pressure at low temperature Until the ethanol is exhausted, and the volume of the concentrated solution reaches 4 times (ratio of ethanol volume (ml) to ginkgo leaf weight (g), V / W), store in 0°C-5°C for 24 hours, take it out, filter, slowly drop in the filtrate Add 95% ethanol until the alcohol concentration of the solution reaches 75%, refrigerate at 0°C-5°C for 24 hours, take it out, filter, concentrate until the ethanol is exhausted, add the filtrate to HPD450 macroporous resin column, first elute with pure water, and react with molish and thin-layer chromatography to control the elution end point, discard the eluent, and then elute with 70% ethanol, collect the eluent, concentrate, and dry to obtain 53.79 kg of Ginkgo biloba extract.

[0042] Ge...

Embodiment 2

[0046] Ginkgo biloba 150kg, pulverized, 8 times (ratio of ethanol volume (ml) and ginkgo biloba weight (g), V / W) 90% ethanol heating and reflux extraction 2 times, each time 2 hours, combined extracts, concentrated under reduced pressure at low temperature Until the ethanol is exhausted, and the volume of the concentrated solution reaches 3 times (ratio of ethanol volume (ml) to ginkgo leaf weight (g), V / W), store in 0°C-5°C for 24 hours, take it out, filter, slowly drop into the filtrate Add 95% ethanol until the alcohol concentration of the solution reaches 75%, refrigerate at 0°C-5°C for 24 hours, take it out, filter, concentrate until the ethanol is exhausted, add the filtrate to a DM130 macroporous resin column, first elute with pure water, and react with molish and thin-layer chromatography to control the elution endpoint, discard the eluent, and then elute with 60% ethanol, collect the eluent, concentrate, and dry to obtain 57.34 kg of Ginkgo biloba extract.

[0047] Ge...

Embodiment 3

[0051] Ginkgo biloba 150kg, pulverized, 12 times (ratio of ethanol volume (ml) to ginkgo biloba weight (g), V / W) 50% ethanol heating and reflux extraction 1 time, 2 hours each time, combined extracts, concentrated under reduced pressure at low temperature Until the ethanol is exhausted, and the volume of the concentrated solution reaches 5 times (ratio of ethanol volume (ml) to ginkgo leaf weight (g), V / W), store in 0°C-5°C for 12 hours, take it out, filter, slowly drop in the filtrate Add 95% ethanol until the alcohol concentration of the solution reaches 75%, refrigerate at 0°C-5°C for 12 hours, take it out, filter, concentrate until the ethanol is exhausted, add the filtrate to HPD700 macroporous resin column, first elute with pure water, and react with molish and thin-layer chromatography to control the elution end point, discard the eluate, and then elute with 80% ethanol, collect the eluate, concentrate, and dry to obtain 60.56 kg of Ginkgo biloba extract.

[0052] Get G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com