Carbon/carbon composite material containing bioactive calcium phosphate coating on surface and preparation method for carbon/carbon composite material

A carbon composite material, bioactive technology, applied in coatings, electrolytic coatings, surface reaction electrolytic coatings, etc., can solve the problems of weak C/C surface bonding, poor stability of HA coating, etc. Good compatibility, easy to metabolize effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

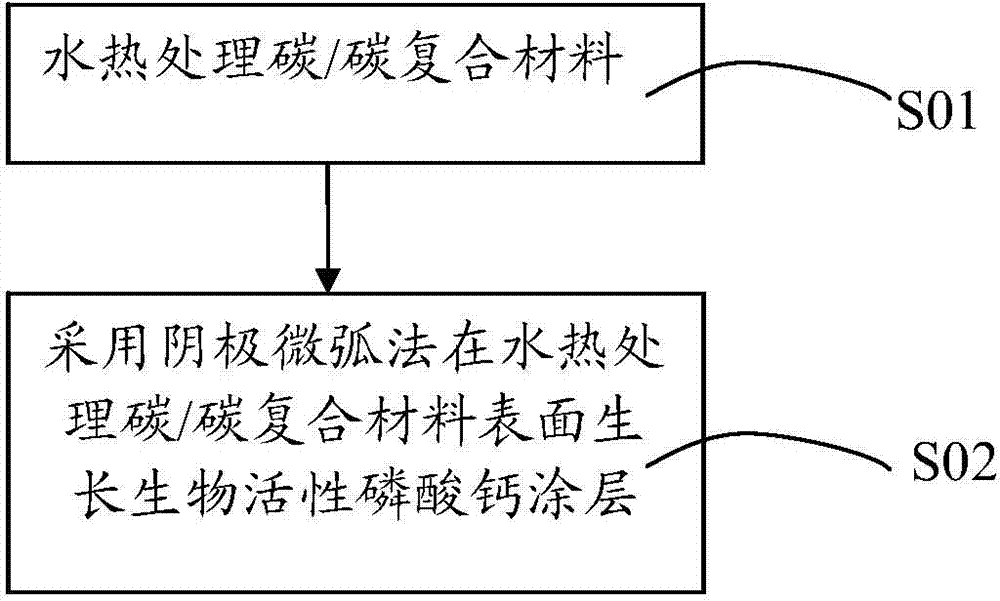

[0025] The embodiment of the present invention provides a method for preparing a carbon / carbon composite material having a bioactive calcium phosphate coating on the surface of the prepared HA coating with high stability and strong bonding with the C / C surface. The preparation method technology of the embodiment of the present invention is as figure 1 As shown, it includes the following steps:

[0026] Step S01. Hydrothermal treatment of the carbon / carbon composite material: placing the carbon / carbon composite material in a solution containing 1-4 mol / L oxidant for hydrothermal treatment, and performing surface treatment on the carbon / carbon composite material;

[0027] Step S02. Using the cathode micro-arc method to grow a bioactive calcium phosphate coating on the surface of the hydrothermally treated carbon / carbon composite material: the carbon / carbon composite material after the hydrothermal treatment is used as the cathode, and the stainless steel is used as the anode, an...

Embodiment 1

[0050] A carbon / carbon composite material with a bioactive calcium phosphate coating on its surface and a preparation method thereof, comprising the steps of:

[0051] S11: 10×10×2mm 3 After grinding and polishing, the carbon / carbon composite material was ultrasonically cleaned with acetone, ethanol, and deionized water in sequence, placed in an aqueous solution of 4mol / L ammonium persulfate, hydrothermally treated at 413K (140°C) for 24h, and cooled Take it out and clean it ultrasonically with deionized water;

[0052] S12: Prepare an ethanol solution containing calcium nitrate at a concentration of 0.01mol / L and phosphorus pentoxide at a concentration of 0.006mol / L; and an ultrasonic nebulizer can be placed in the solution to make the solution ultrasonically bubble;

[0053] S13: Soak the treated carbon / carbon as the cathode and the stainless steel as the anode in the solution described in S12, and apply a voltage, the pulse voltage is 450V, the pulse frequency is 600Hz, th...

Embodiment 2

[0058] A carbon / carbon composite material with a bioactive calcium phosphate coating on its surface and a preparation method thereof, comprising the steps of:

[0059] S21: Will be 10×10×2mm 3 After grinding and polishing, the carbon / carbon composite material was ultrasonically cleaned with acetone, ethanol, and deionized water in sequence, placed in a 1mol / L hydrogen peroxide aqueous solution, hydrothermally treated at 99°C for 12h, cooled, taken out, and used Ultrasonic cleaning with ionized water;

[0060] S22: Prepare an ethanol solution containing 0.4 mol / L calcium nitrate and 0.4 mol / L triethyl phosphate, ethylene glycol and glycerin account for 30% of the volume of the ethanol solution; wherein the volume ratio of ethylene glycol and glycerin is 1 :50;

[0061] S23: Soak the treated carbon / carbon as the cathode and the stainless steel as the anode in the solution described in S22, and apply a constant voltage mode voltage of 500V for 12 hours;

[0062] S24: Take it o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com