Preparation method of liposome and product prepared by preparation method of liposome

A technology of liposomes and plastids, which is applied in liposome delivery, medical preparations containing active ingredients, pharmaceutical formulas, etc., and can solve problems such as uneven particle size distribution of liposomes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

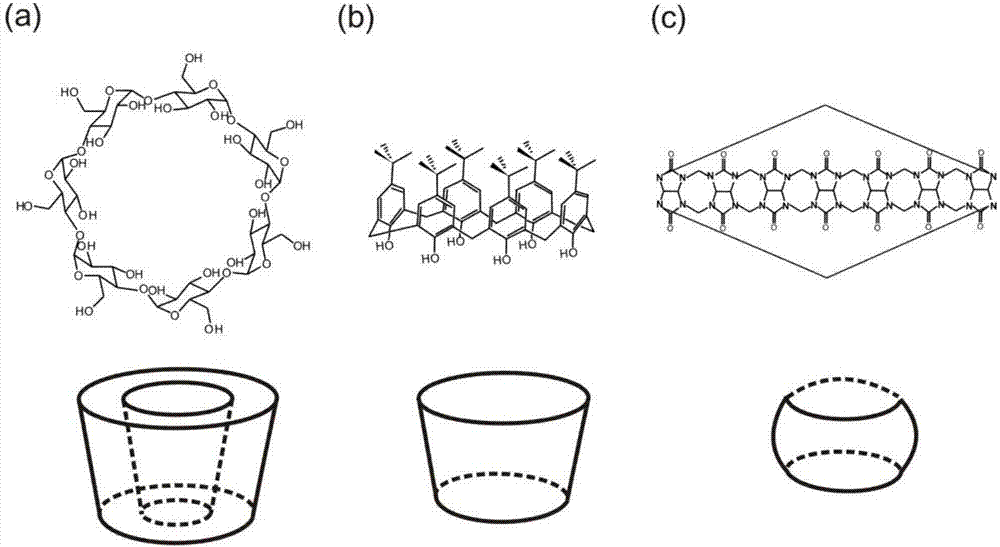

Method used

Image

Examples

Embodiment 1

[0116] Example 1 Preparation of very small liposomes of monophospholipid components (the molar ratio of guest molecule to host molecule is 1:5)

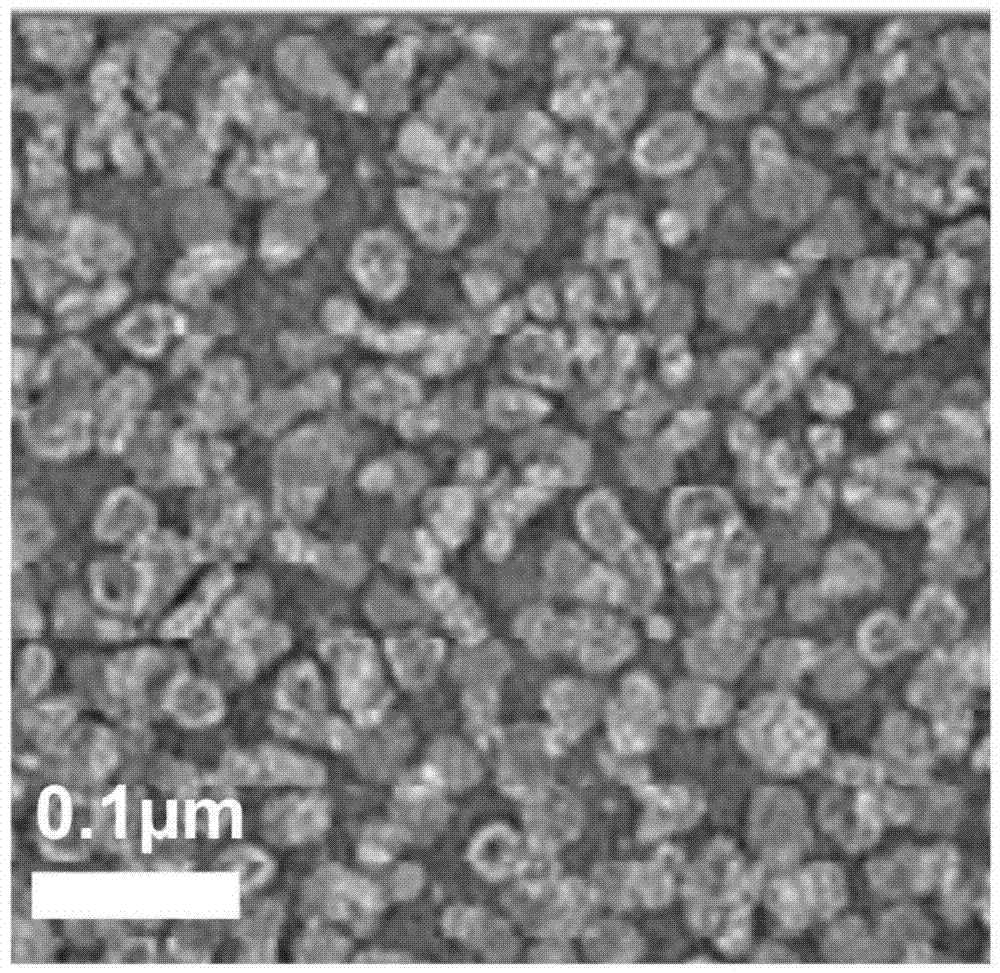

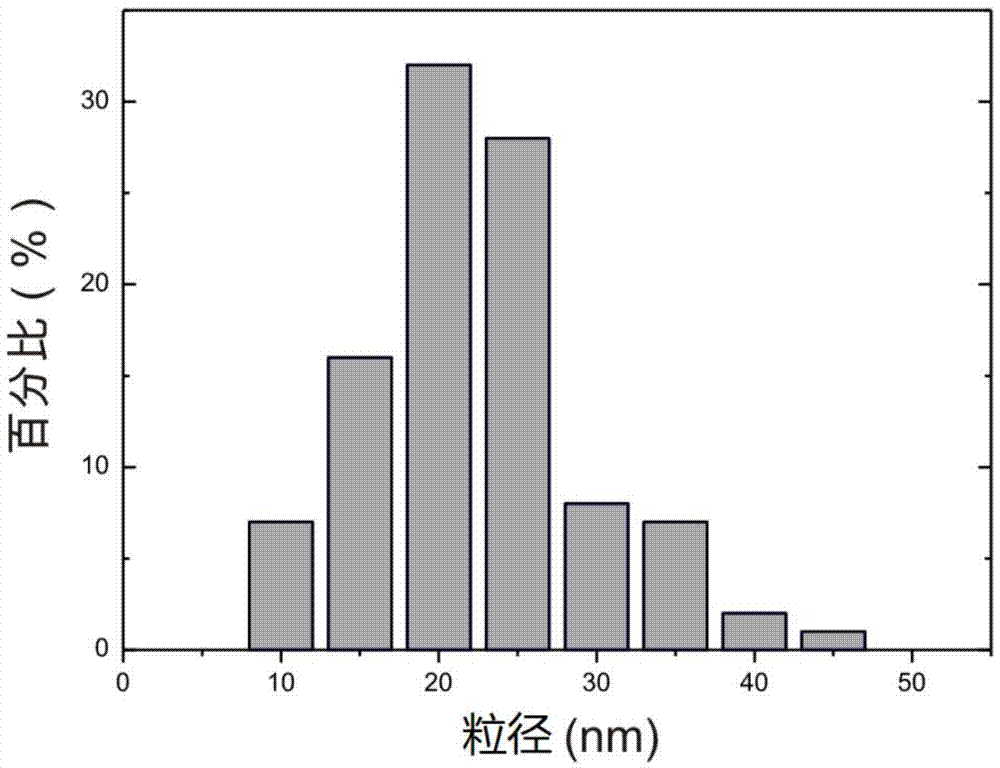

[0117] Dissolve 0.01 g of 1-stearoyl-2-oleoyl lecithin (chemical name 1-stearoyl-2-oleoyl-sn-glyceryl-3-phosphocholine, SOPC, molecular weight 788) with 25 ml of chloroform , into a 100 ml round bottom flask, and evaporate the solvent to dryness under reduced pressure. Add 50 mL of phosphate-buffered saline solution containing 1 mmol / L n-dodecyl-β-D-maltoside (nonionic surfactant) to the round bottom flask, pH 7.4. SOPC was completely dissolved in the nonionic surfactant phosphate buffered saline by shaking the round bottom flask. 0.33 g of γ-cyclodextrin (molecular weight 1297) was dissolved in 50 ml of water at room temperature (25° C.) to obtain a 5 mmol / L aqueous solution of γ-cyclodextrin. The SOPC solution was added to the aqueous γ-cyclodextrin solution and mixed under vigorous stirring for 15 minutes. In this way, the SOPC...

Embodiment 2

[0120] Example 2 Preparation of very small liposomes of monophospholipid components (the molar ratio of guest molecule to host molecule is 1:2)

[0121] Dissolve 0.16 g of 1-stearoyl-2-oleoyl lecithin in 50 ml of chloroform, put it into a 250 ml round bottom flask, and evaporate the solvent to dryness under reduced pressure. Into the round bottom flask was added 100 ml of pH 7.4 phosphate buffered saline solution containing 8 mmol / L of n-dodecyl-β-D-maltoside (non-ionic surfactant). SOPC was completely dissolved in the nonionic surfactant phosphate buffered saline by shaking the round bottom flask or applying magnetic stirring. 2.1 g of γ-cyclodextrin was dissolved in 100 ml of room temperature (25° C.) water. The resulting SOPC solution was mixed with the 100 ml aqueous solution of γ-cyclodextrin under vigorous stirring for 15 minutes at room temperature. In this way, the SOPC single-component ultrafine liposome solution is prepared. The particle size of the ultrafine lipo...

Embodiment 3

[0122] Embodiment 3 prepares solid single phospholipid component very small liposome

[0123] 0.32 g of 1-stearoyl-2-oleoyl lecithin (SOPC, molecular weight 788) was dissolved in 50 ml of chloroform, put into a 250 ml round bottom flask, and the solvent was evaporated to dryness under reduced pressure. Add 100 ml of phosphate buffered saline solution containing 16 mmol / L nonyl-β-D-glucoside (non-ionic surfactant) to the round bottom flask, pH 7.4, stir and warm the solution to 55°C , so that SOPC is completely dissolved in the non-ionic surfactant phosphate-buffered saline. Dissolve 4 g of β-cyclodextrin in 100 ml of water at 55°C and keep warm. Mix under vigorous stirring for 15 minutes. Thus, SOPC single-component extremely tiny liposomes are prepared. When standing to room temperature, a pale yellow cyclodextrin-nonylglucoside complex precipitated, and the precipitate was removed by filtration. Continue to lower the temperature to 4°C, precipitate the cyclodextrin-nonyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com