Polyethylene micropore diaphragm containing organic/inorganic composite cross-linking coating and preparation method of polyethylene micropore diaphragm

A polypropylene microporous membrane and inorganic composite technology, which is applied in the direction of separators/films/diaphragms/spacers, electrical components, circuits, etc., can solve the problem of insufficient binding force, affecting battery performance, coating and diaphragm binding force Poor and other problems, to achieve the effect of increasing the temperature of thermal shrinkage film rupture, improving the safety performance of use, and high closed cell temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

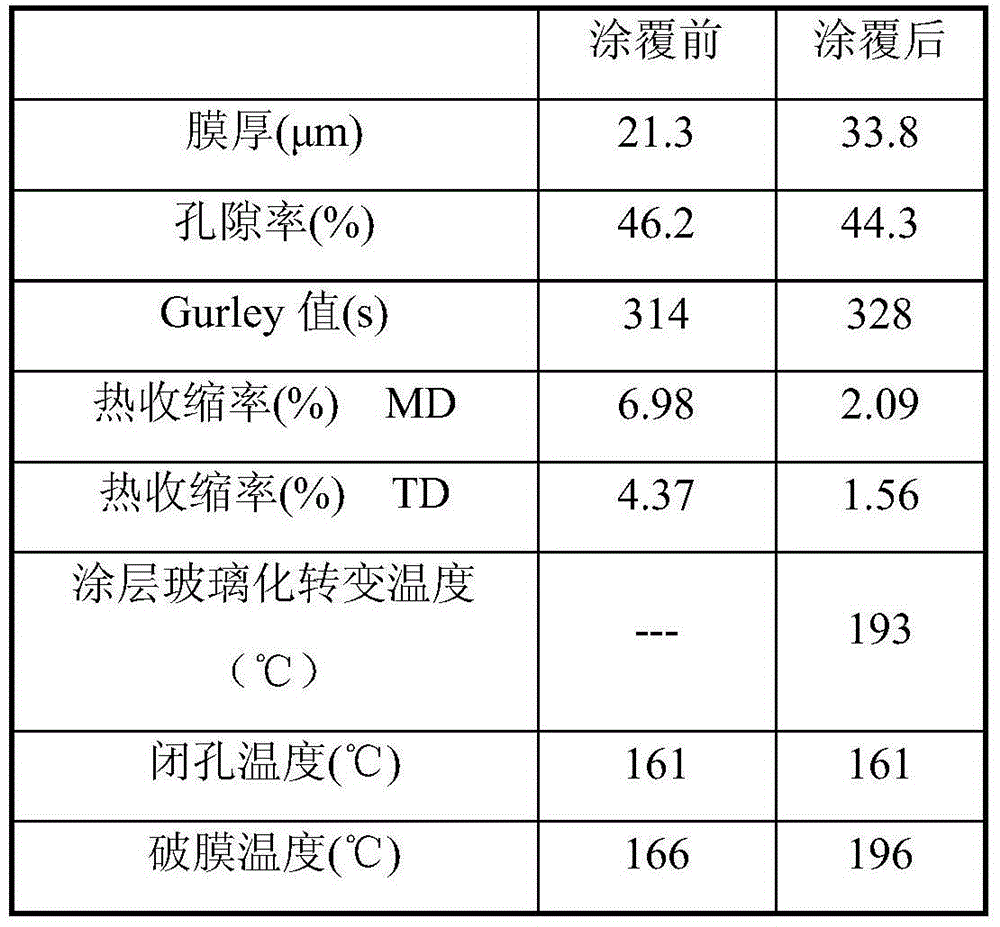

[0038] The polypropylene microporous membrane prepared by the uniaxial stretching process is used as the coating base membrane, with a thickness of 21.3 μm, a porosity of 46.2%, and a Gurley value reflecting the air permeability of 157s. The two surfaces of this polypropylene microporous membrane are subjected to the same degree of normal temperature and low pressure plasma treatment, and air is used as the treatment atmosphere, and the base membrane is treated for 30 seconds at room temperature (25 ° C), 45W power and 60Pa vacuum condition, and the plasma The water contact angle of the basement film surface decreased from 103° to 25° after bulk treatment, and the treated basement film was used for the coating process within 15 minutes.

[0039] The aromatic isocyanate is a mixture of naphthalene diisocyanate (NDI) and trimeric isocyanate (the molar ratio is 50:50), with a molecular weight of 1000, an average functionality of 3, a hydroxyl value of 166mgKOH / g, and p-phenylene i...

Embodiment 2

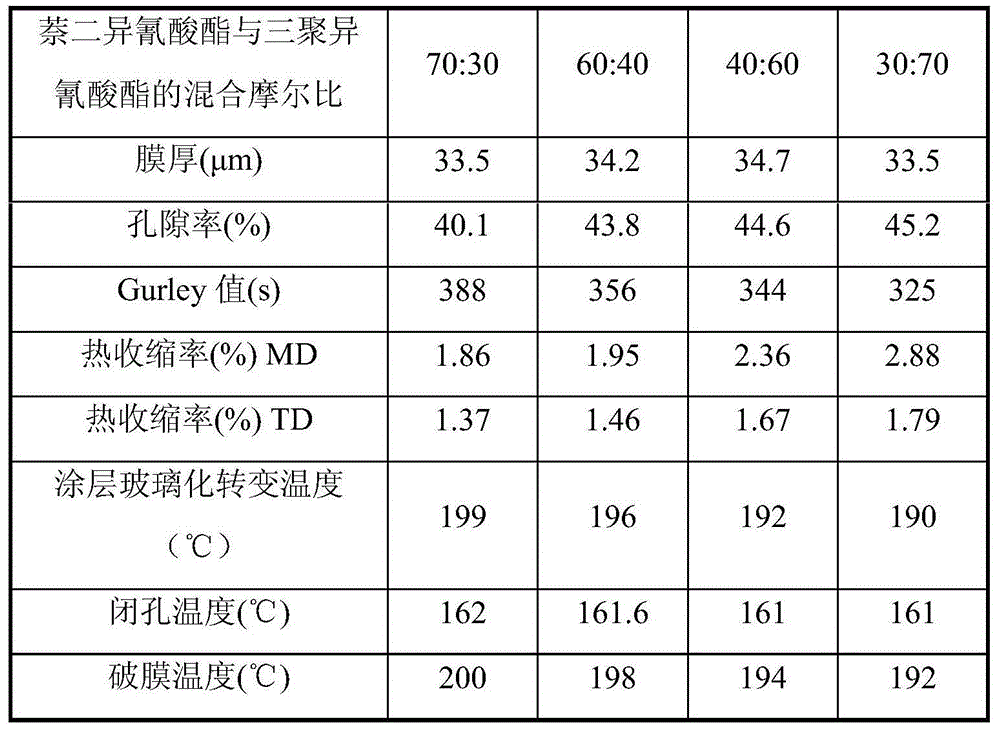

[0045] The polypropylene microporous membrane in Example 1 was used as the coating base membrane. The mixing molar ratio of naphthalene diisocyanate and trimeric isocyanate in the example 1 coating solution is changed to 30:70, 40:60, 60:40 and 70:30 respectively from 50:50, other components in the coating solution and The dosage was still the same as in Example 1, and four coating solutions were prepared respectively. Then according to the coating process and curing process in Example 1, four kinds of polypropylene microporous membranes with different cross-linked composite coating structures were prepared respectively. The results of the tests on these four microporous membranes are listed in Table 2.

[0046] Table 2 Performance of crosslinked composite coating PP microporous membrane in Example 2

[0047]

[0048] From the test results in Table 2 and Table 1, it can be seen that changing the mixing molar ratio of naphthalene diisocyanate and isocyanurate in aromatic i...

Embodiment 3

[0050] The polypropylene microporous membrane in Example 1 was used as the coating base membrane. In the coating solution of Example 1, the molecular weight is 1000, the average functionality is 3, the aromatic polyester with a hydroxyl value of 166mgKOH / g, and the molar ratio of terephthalic acid and phthalic anhydride in the molecular chain is 65:35, respectively Replace it with aromatic polyester polyols with molecular weights of 500, 1500, and 2000. Their hydroxyl values are 332, 112, and 84 mgKOH / g, respectively, and the molar ratio of terephthalic acid to phthalic anhydride in the molecular chain is 65. :35. The other components and dosages in the coating solution were still the same as in Example 1, and three coating solutions were prepared respectively. Then according to the coating process and curing process in Example 1, three kinds of polypropylene microporous membranes with different cross-linked composite coating structures were prepared respectively. The resu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com